Multi-layer co-extrusion film-blowing equipment and multi-layer co-extrusion film-blowing technique

A multi-layer co-extrusion and process technology, which is applied in the field of plastic product production equipment and plastic product production technology, can solve the problems of floating point easy to fall off, high cost, low adhesion between floating point and smooth surface, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

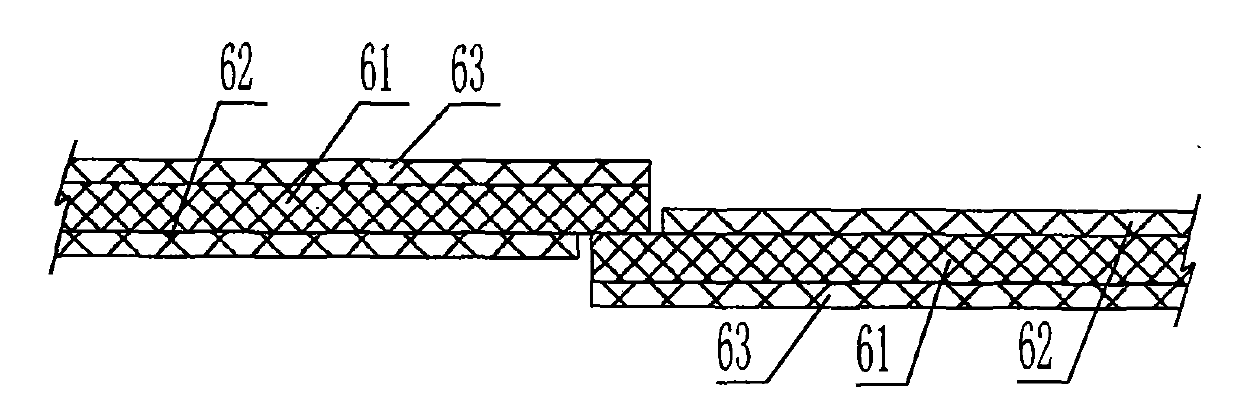

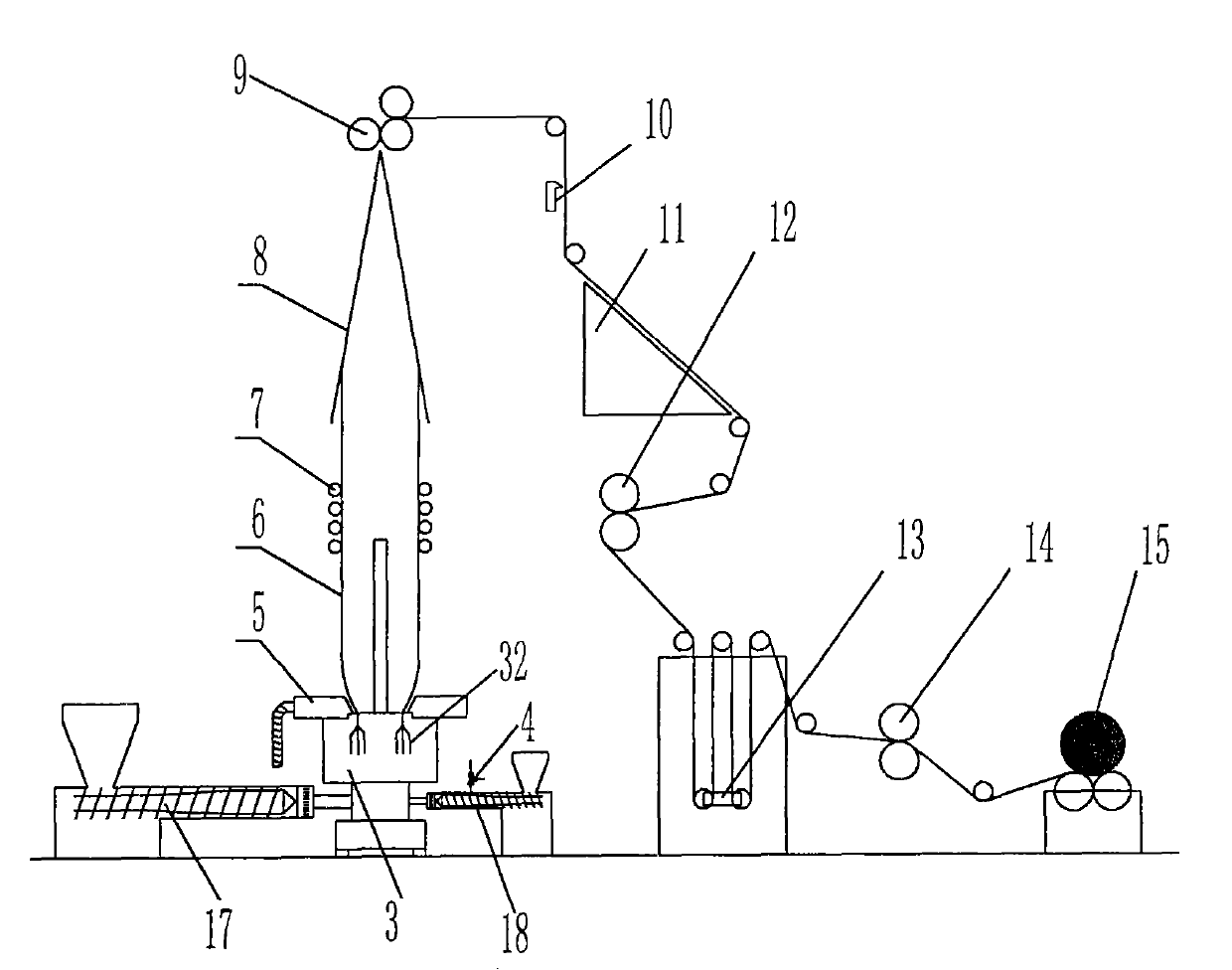

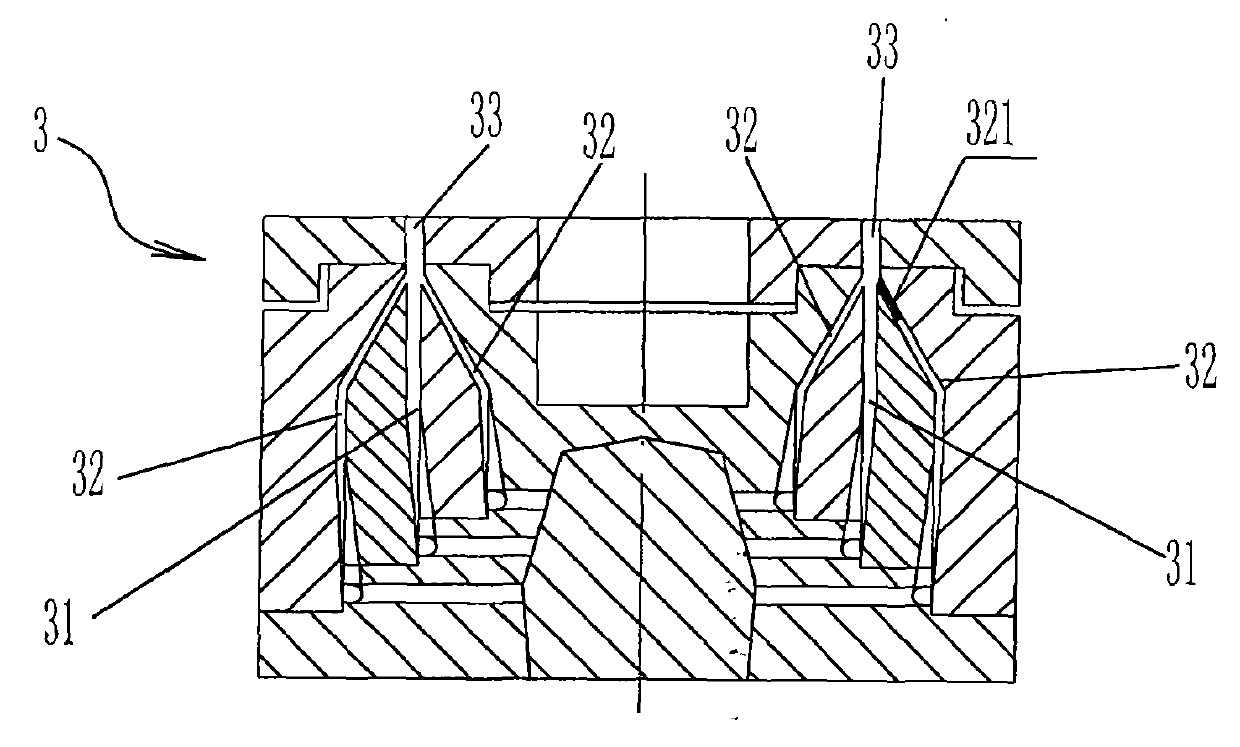

[0029] figure 1 , figure 2 , Figure 4 As shown, an embodiment of the present invention is a three-layer co-extrusion blown film equipment, including a base layer extruder 17, two surface layer extruders 18, a film blowing head 3, a cooling air ring 5, and a bubble stabilizer 7 , Herringbone splint 8, first traction device 9, cutting device 10, unfolding device 11, flattening device 12, film storage device 13, second traction device 14, coiling device 15. The film blowing head 3 is provided with an annular die opening gap 33 and three annular flow channels, wherein two annular flow channels (the annular flow channels positioned inside and outside) are surface layer annular flow channels 32, and the other annular flow channel (the one located in the middle Annular flow channel) is the base annular flow channel 31, each surface layer annular flow channel 32 is correspondingly connected to one of the surface layer extruders 18, and the base layer annular flow channel 31 is cor...

Embodiment 2

[0032]Embodiment 2 is a three-layer co-extrusion blown film equipment. The blown film head 3 is provided with two surface layer annular flow channels 32 and a base layer annular flow channel 31. Each surface layer annular flow channel is connected to a surface layer extruder correspondingly. Each base annular channel is correspondingly connected with a base extruder, and each surface extruder and base extruder are respectively provided with a barrel and a screw, and the screw is provided with a feeding section, a compression section, and a metering section. In addition, among the two surface layer extruders, the screw of one surface layer extruder is also equipped with an air-filling section, and the side wall of the barrel corresponding to the position of the air-filling section is also provided with a gas input port, and the gas input port is connected to a gas The input device; the screw of the other surface layer extruder does not have an air filling section. In embodiment...

Embodiment 3

[0035] Embodiment 3 is a five-layer co-extrusion blown film equipment, the film blowing machine head is provided with two surface layer annular flow channels and three base layer annular flow channels, and the screws of the two surface layer extruders are equipped with air-filling sections, and the air-filling The screw groove depth of the section is equivalent to 5 times the screw groove depth of the metering section, and a gas input port is opened on the side wall of the barrel at the corresponding position of the gas filling section, and the gas input port is connected to a gas input device. The corresponding surface annular runners of the two surface extruders are provided with detachable arc-shaped small stoppers. The three-dimensional shape of the arc-shaped small stopper is tile-shaped, and can be installed in the annular flow channel when needed.

[0036] In the above embodiment, the depth of the screw channel in the air-filling section can be designed to be 7 times or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com