Motor vehicle brake stick and novel braking system

A brake system and brake rod technology, applied in the direction of brakes, brake components, vehicle parts, etc., can solve the problems of complex machinery, prone to failure, long process, etc., and achieve the effect of improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

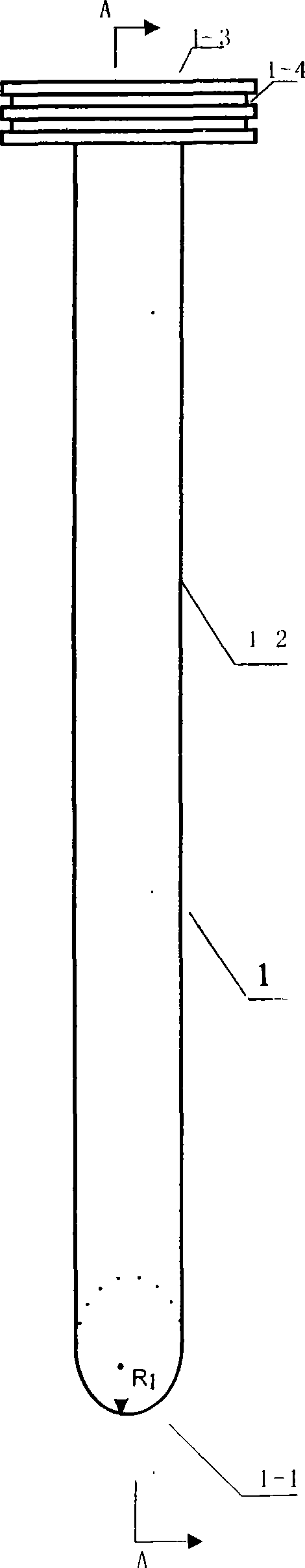

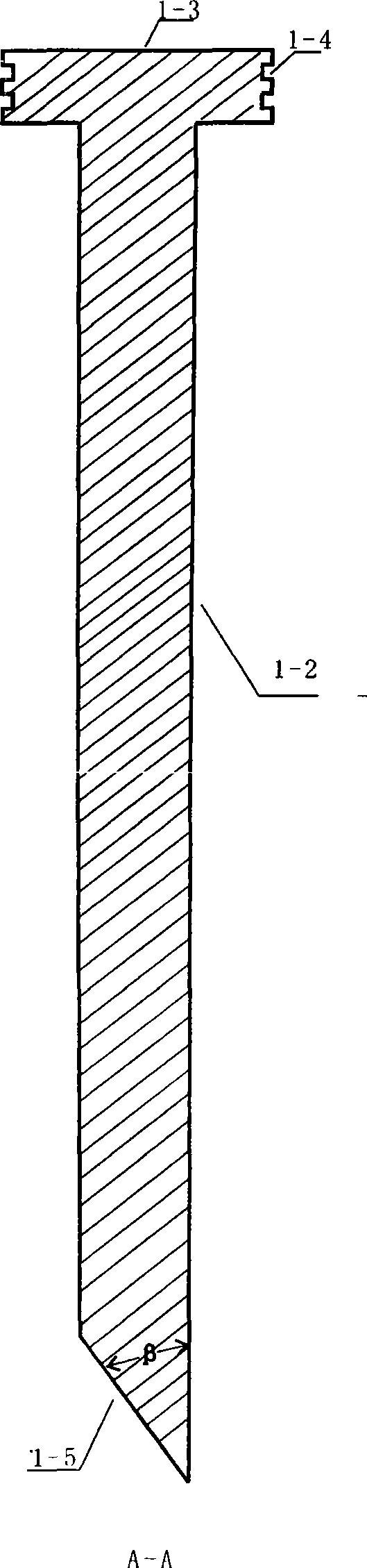

[0042] like figure 1 and figure 2 Shown is an A-1 type brake rod 1, which is a component directly used for braking in the brake system. The brake rod is a cylinder 1-2 with changes in its upper and lower ends, and its upper end is directly connected to a piston. 1-3, 1-4 are piston ring grooves, the front of the lower end is an arc 1-1 of an ellipse, and one of the radii of the ellipse is R 1 , its lower end side is a sharp bullhorn 1-5, and its angle is wedge angle β; the brake rod is made of tough material such as alloy steel, and the tip should be heat-treated to improve hardness and comprehensive performance.

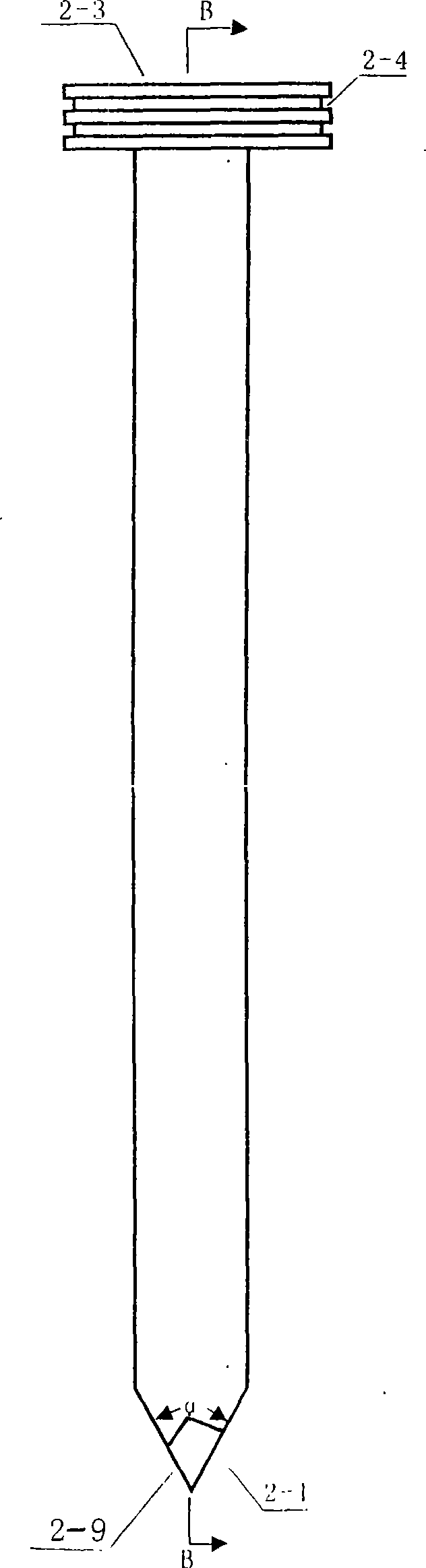

[0043] like image 3 and Figure 4 Shown is the A-2 type brake rod 2, which is an improved version of the A-1 type brake rod. In order to make the brake rod stronger and reduce resistance during work, and work more reliably, the lower end of the brake rod 1 The front is made into an acute angle ∠α, which becomes 2-1 of the brake rod 2, that is, the tool tip an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com