Ring surface enveloped non-clearance worm and gear speed-reduction apparatus

A technology of worm gear and reduction gear, applied in the direction of gear transmission, hoisting device, transmission device, etc., can solve the problems of reducing transmission accuracy, increasing transmission clearance, unable to meet transmission requirements, etc., so as to improve transmission precision and eliminate clearance. , the effect of enhancing the stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

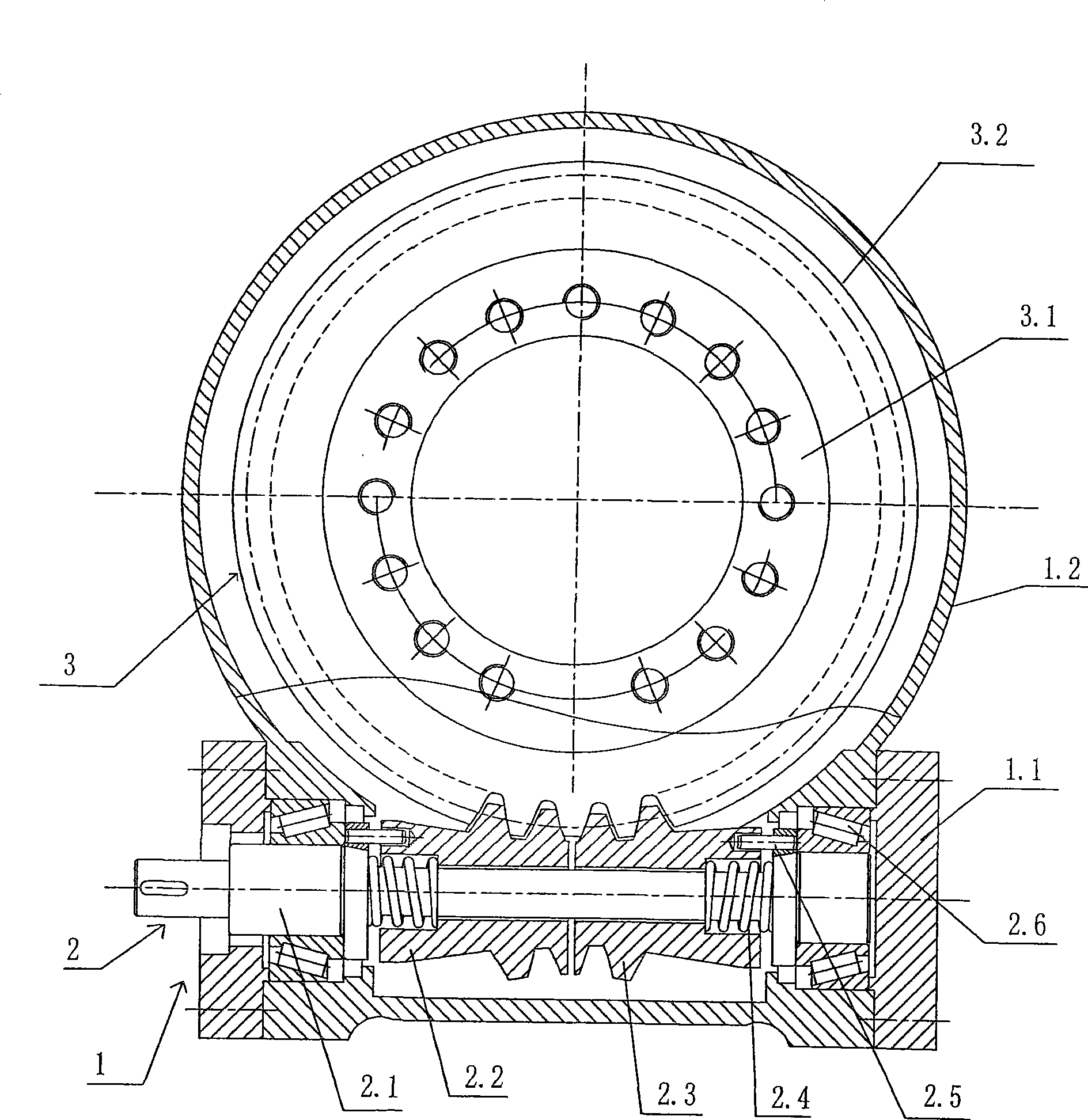

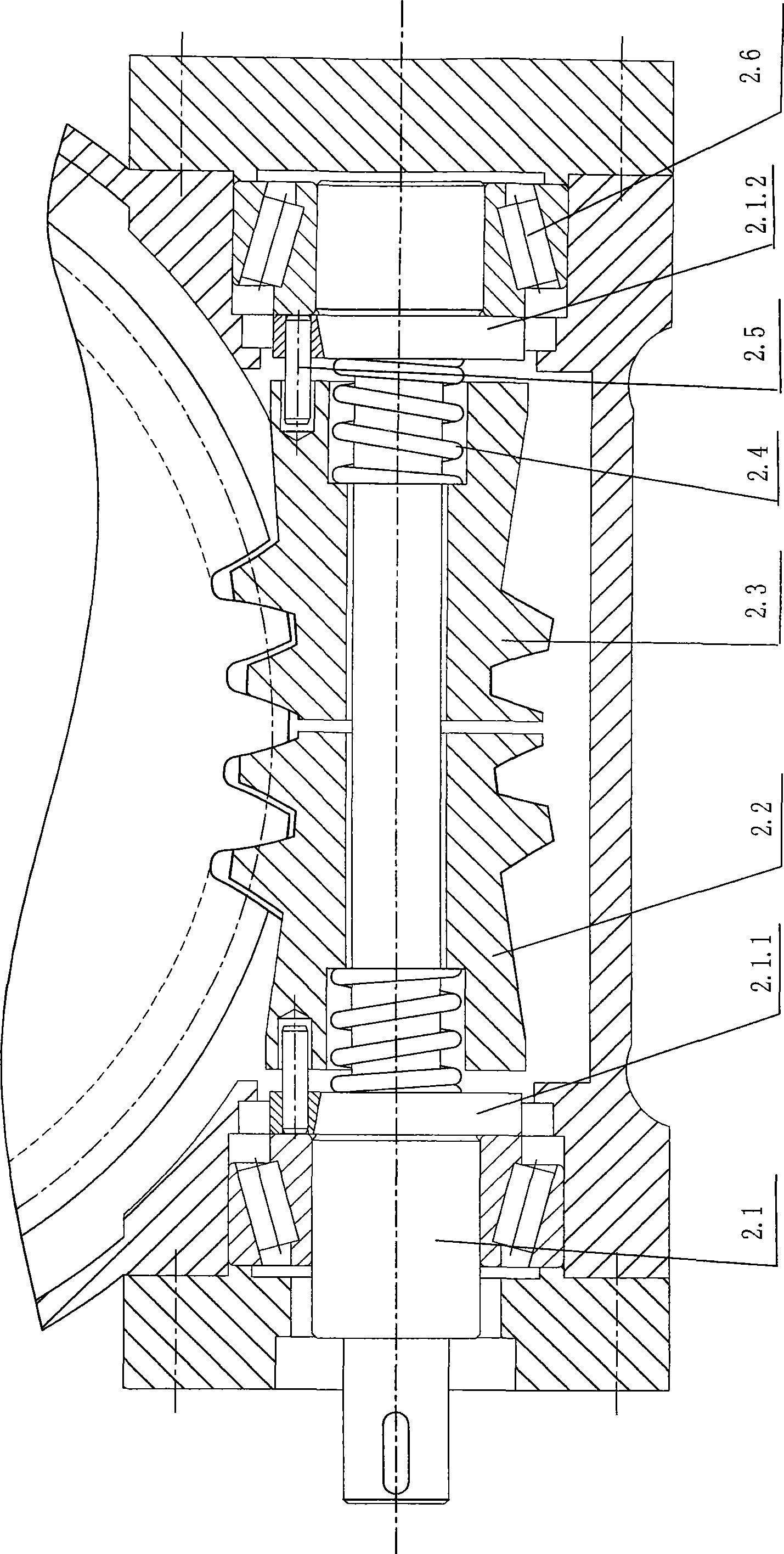

[0015] see Figure 1-2 , The present invention envelops the gapless worm gear reducer, which is mainly composed of a base 1, a worm 2 and a slewing bearing 3. The base 1 includes a shaft housing 1.1 on which the worm 2 is installed and a seat ring 1.2 on which the slewing bearing 3 is installed, and the shaft housing 1.1 and the seat ring 1.2 are integrally connected. The axis line of the shaft housing 1.1 and the axis line of the seat ring 1.2 are perpendicular to each other in space. An opening is provided on the shell wall of the shaft shell 1.1 close to the raceway 1.2 to expose the toothed part in the middle of the worm.

[0016] The worm 2 is installed in the shaft housing 1.1 of the base 1, and the worm 2 is mainly composed of a mandrel 2.1, a left half worm 2.2, a right half worm 2.3, a spring 2.4 and a dial pin 2.5. The mandrel 2.1 is installed in the shaft housing 1.1 through a bearing 2.6, the left half worm 2.2 is axially provided with stepped holes from left to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com