Special weft airflow acting force test device for main nozzle of jet loom

An air-jet loom and testing device technology, applied in tension measurement and other directions, can solve the problems of improvement, disadvantageous air-jet loom performance, inability to obtain accurate and effective actual data, etc., and achieve the effect of improving research work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

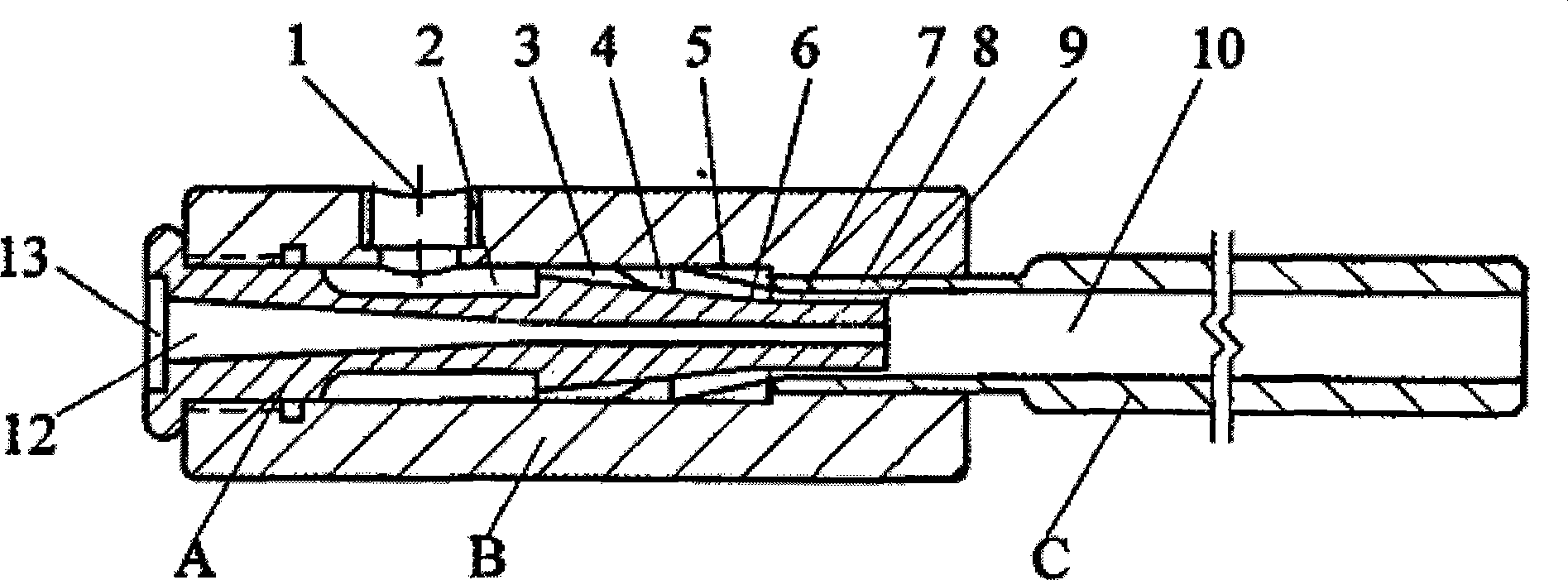

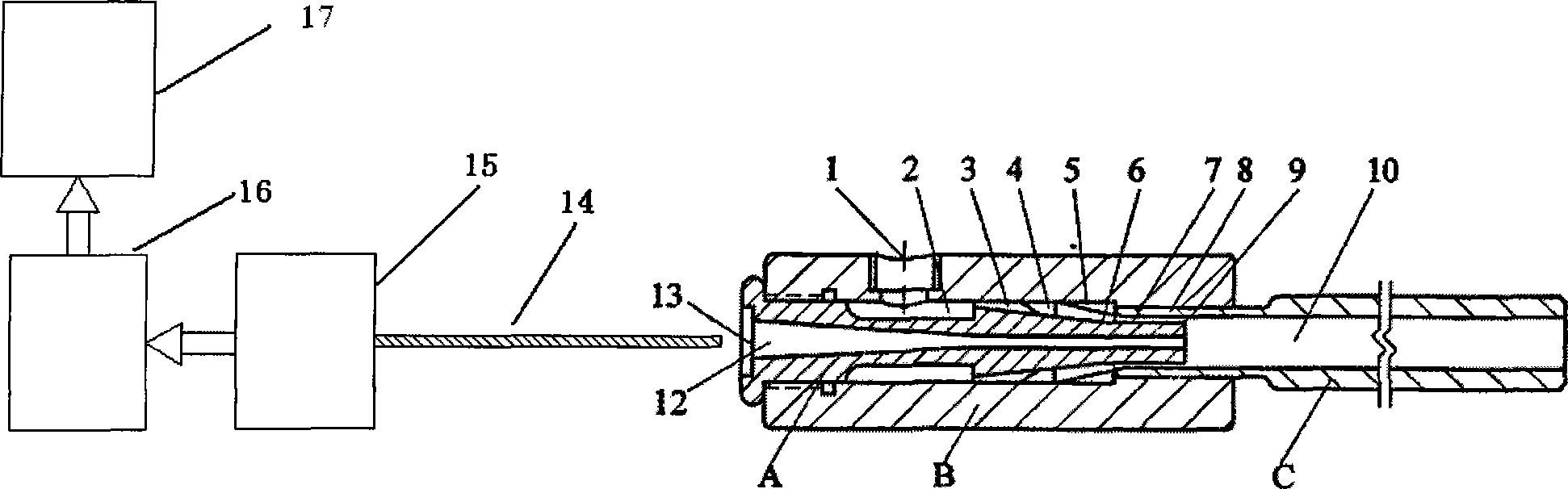

[0013] A device for testing the weft airflow action force of the main nozzle of an air-jet loom, which is composed of a main nozzle of a simulated air-jet loom, a tension sensor 15, a data acquisition card 16, a computer 17 and a measured yarn 14, and the simulated main nozzle of an air-jet loom includes Nozzle core A, nozzle body B and yarn guide tube C. The central line of the main nozzle of the simulated air-jet loom and the tension sensor 15 are located on the same horizontal plane, one end of the yarn 14 to be tested is fixed at the center of the tension sensor 15, and the other end is in a free state.

[0014] When the compressed air enters the first air chamber 2 through the air inlet 1 to form a high-speed vortex, then passes through the rectification groove 3 to adjust the flow direction of the air flow, passes through the wake area 4 and the tapered sleeve 5, passes through the subsonic acceleration area 6, and finally passes through the throat 7 reaches the speed of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com