Setting method for photo-etching system NA-sigma

A lithography system and lithography technology are applied in the direction of photolithography for photomechanical processing of originals, optics, and patterned surfaces. It can solve problems such as reducing OPC efficiency, abnormal data processing, and OPC complexity. Achieve the effects of reducing complexity, improving correction efficiency, and saving data processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

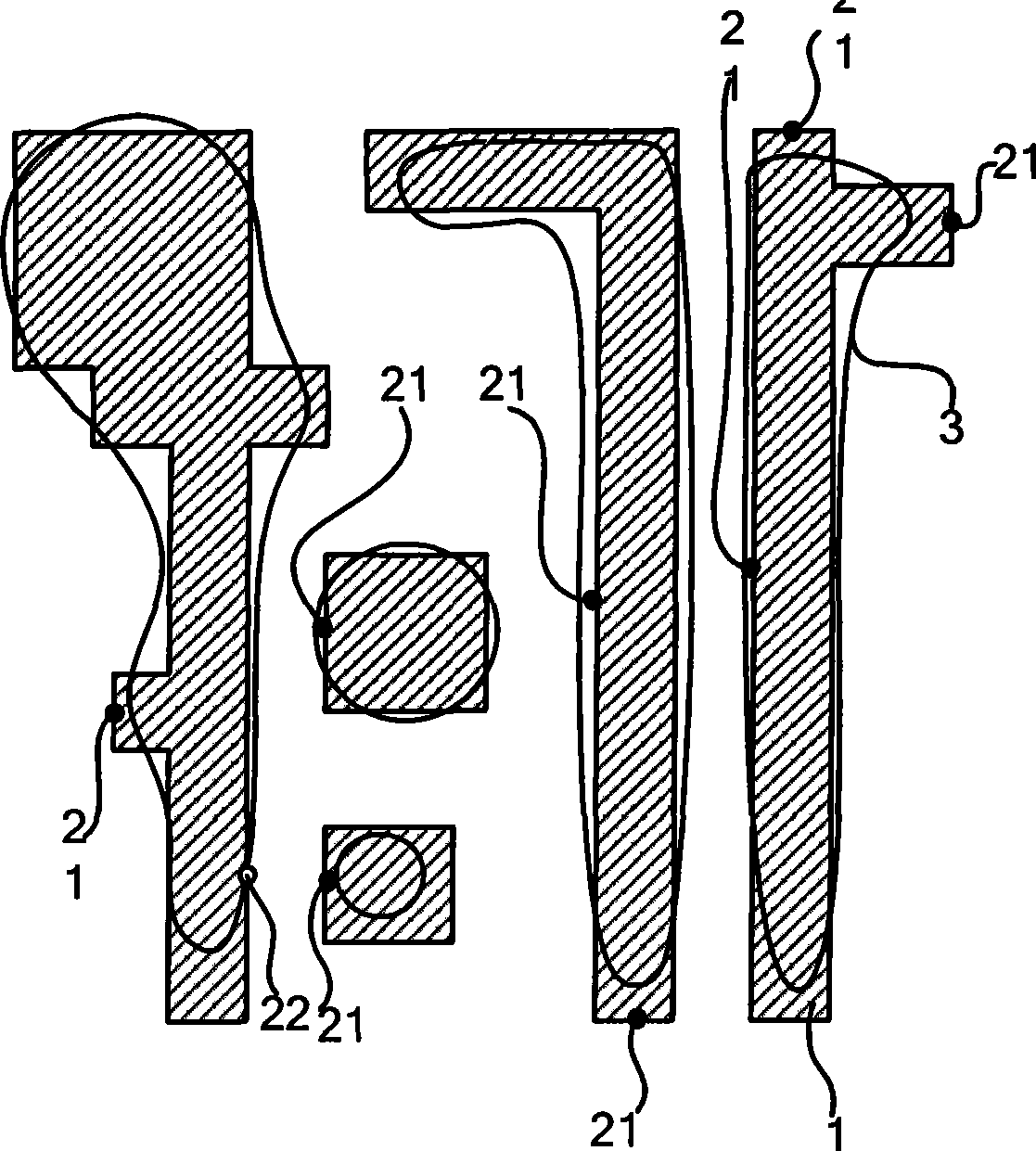

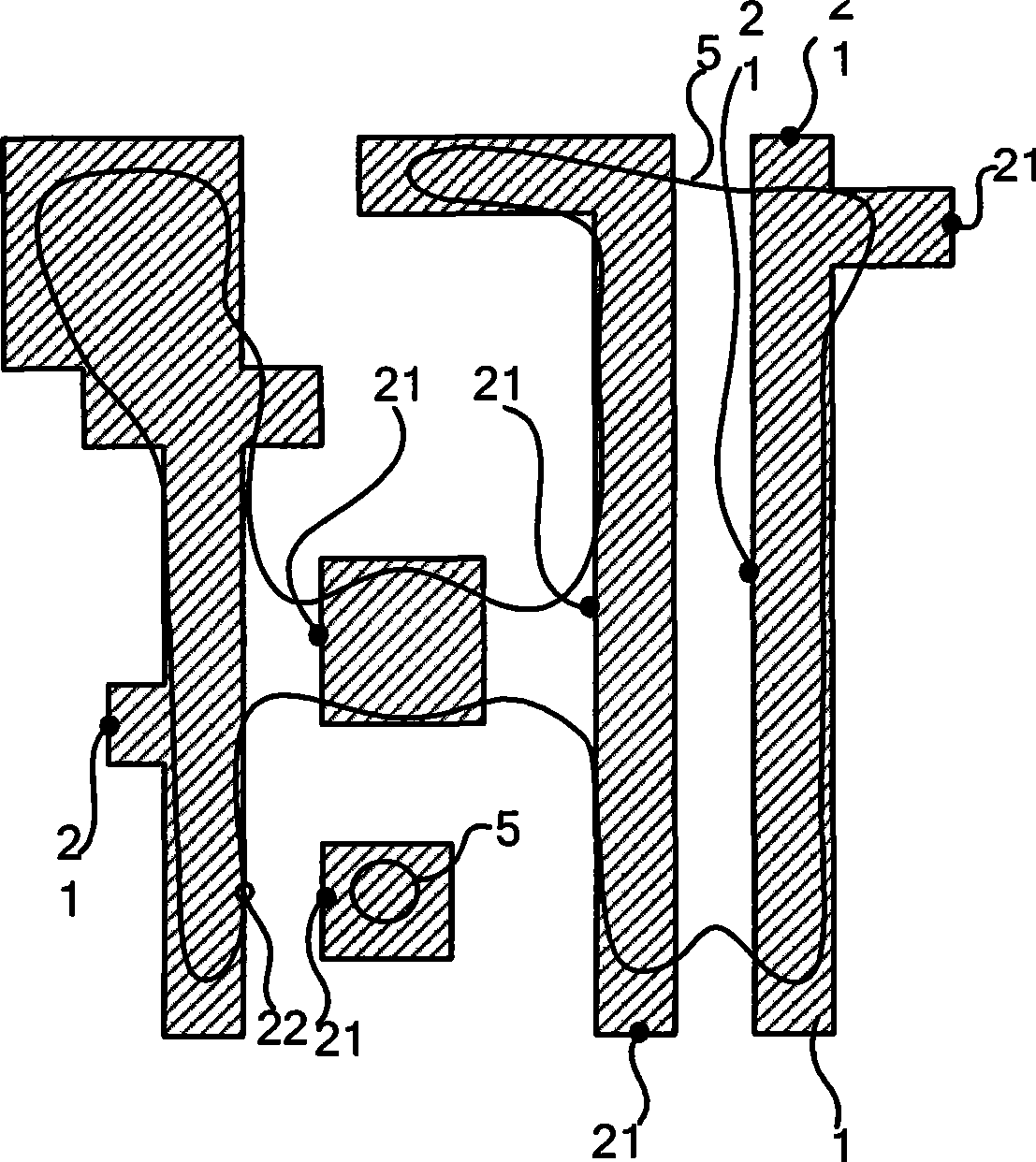

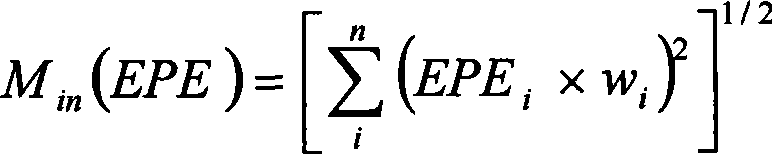

[0019] According to the traditional NA-σ setting method of the lithography system, a series of NA-σ values of the lithography system with a larger lithography window for a design pattern with a certain feature size, ie, a larger M value, are obtained. For example, under the same NA value, one is a ring illuminator and the other is a quadrupole illuminator. The illuminator with these two different σ values has a larger photolithographic process window when exposing a pattern of a certain feature size, that is, it is relatively small. Large M value. First, under a series of NA-σ setting values of the lithography system obtained with a larger lithography window, several monitoring points are positioned according to a design pattern with a certain feature size. Generally speaking, to locate monitoring points is to locate these monitoring points according to some key parts in the pattern to be designed and the design characteristics of the pattern. see figure 1 , the design...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com