Magnetic force torque converter

A torque converter and magnetic technology, applied in the field of torque converters, can solve the problems of large energy loss, low efficiency, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

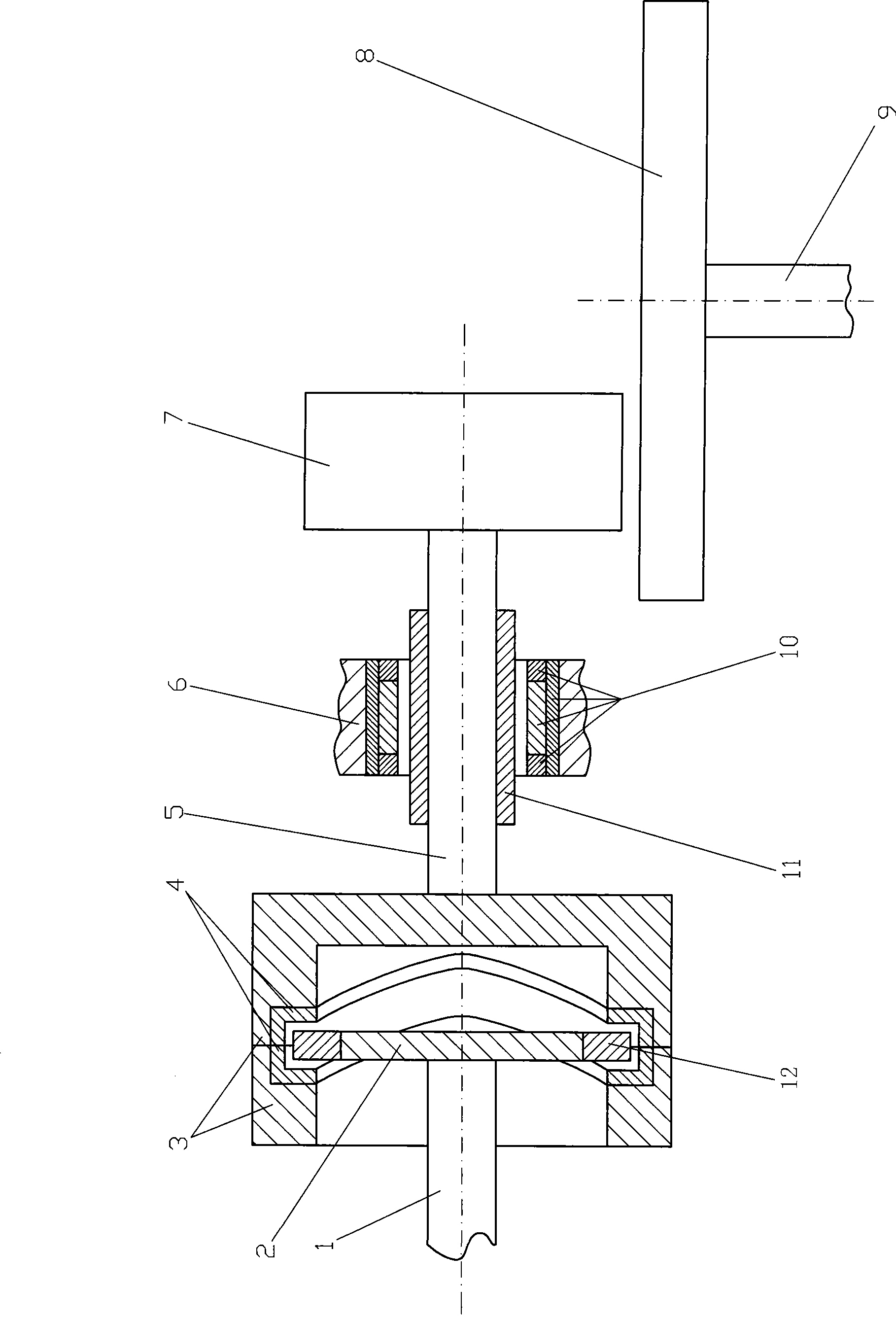

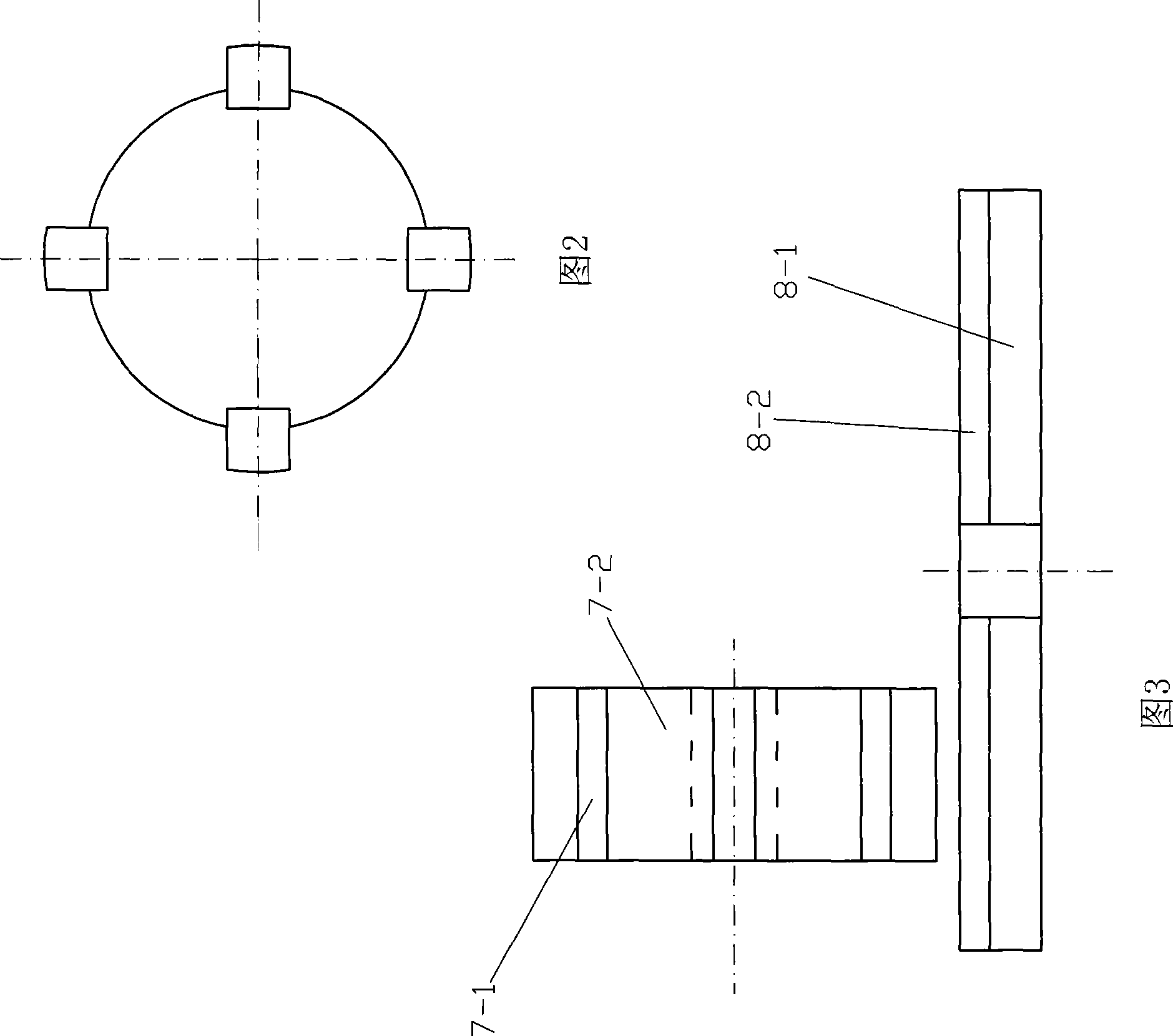

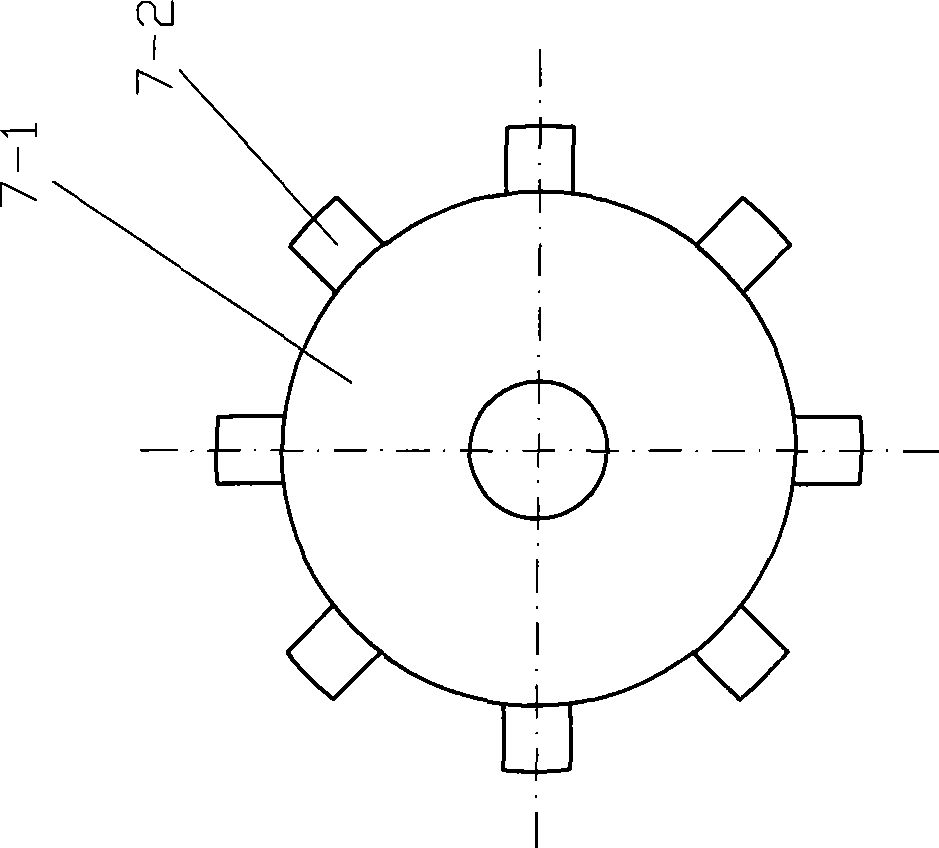

[0046] Such as figure 1 , Figure 2 shows that the right end of the power input shaft 1 is coaxially connected to the disk 2, and several combined permanent magnets 12 are consolidated on the disk 2, and the cylinder 3 combined in the axial direction is arranged, and the first and last phases are formed inside it. Connected wave-shaped combined permanent magnet groove 4, permanent magnet 12 inserts in the permanent magnet groove 4 but leaves a gap of the groove wall of permanent magnet groove 4, and makes permanent magnet 12 and the groove wall of permanent magnet groove 4 opposite to each other, permanent magnet 12 Due to the repulsive force of the permanent magnet groove 4, it is suspended in the permanent magnet groove 4; the transmission shaft 5 is coaxially connected with the right end of the cylinder 3 and the left end of the magnetic transmission wheel 7. When installing, the transmission shaft 5 is coaxial with the shaft 1, and the transmission The magnetic bearing inne...

Embodiment 2

[0057] In Embodiment 1, the magnetic transmission wheel 7 and the magnetic transmission disc 8 can be replaced with a coaxial transmission gear pair transmission mechanism. Such as Figure 15 Figure and Figure 16 As shown, the magnetic transmission wheel 7 is replaced by the ring gear 17, the magnetic transmission disc 8 is replaced by the gear 18 coaxial with the ring gear 17 and meshed with the transmission, and the output shaft 19 is coaxially connected with the right end face of the internal gear 18; The ring gear 17 and the gear 18 are exchanged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com