A method of treating an electrically insulating oil

An electrical insulating oil and oil treatment technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of complex process and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] A detailed description of the preferred embodiments is provided herein. However, it should be understood that the invention may be embodied in a variety of forms. Therefore, specific details disclosed herein are not to be interpreted as limiting, but rather as a basis for the claims and as a practical basis for teaching one skilled in the art to employ the invention in any suitably detailed system, structure or manner.

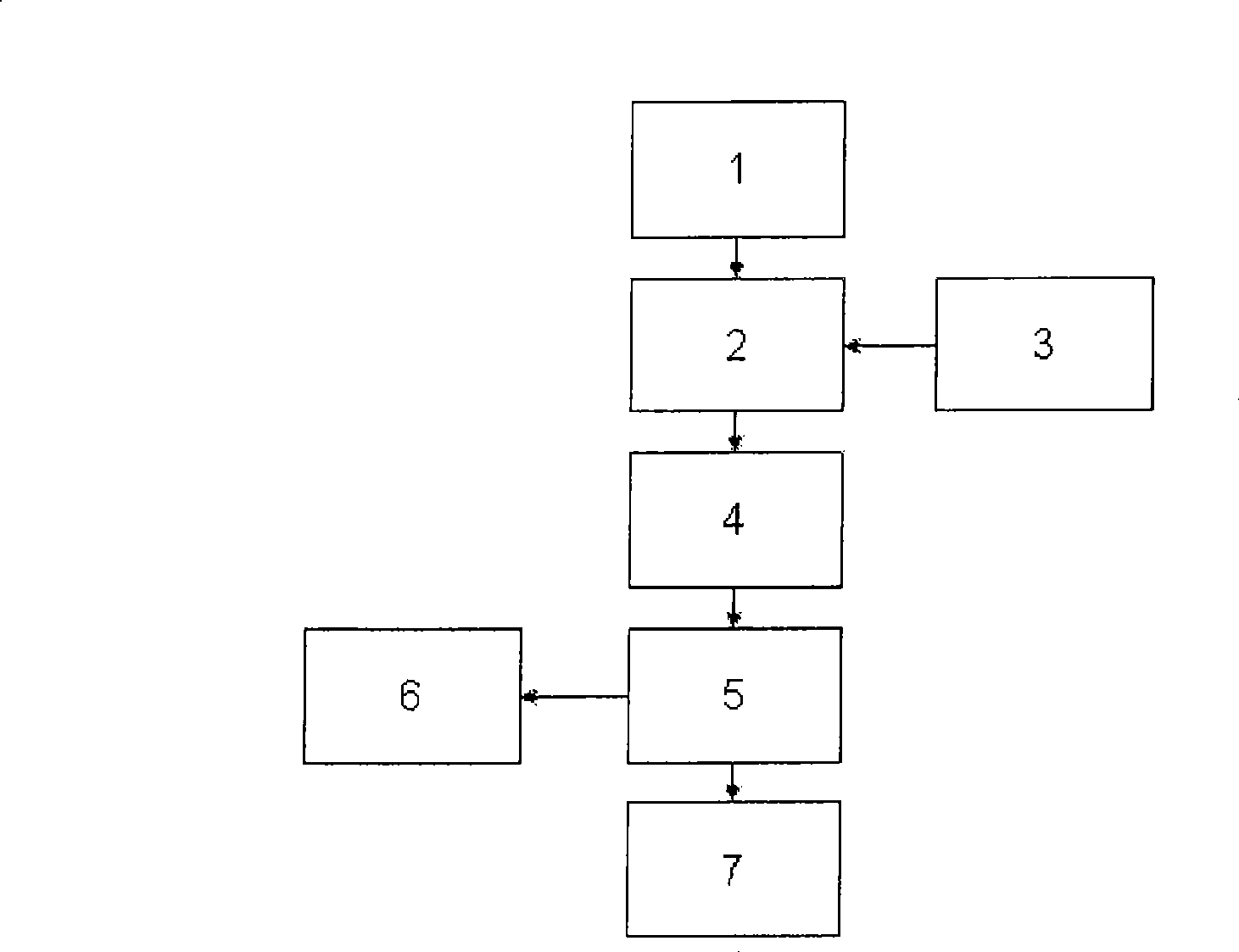

[0047] figure 1 A schematic process diagram of the method is shown. In Block 1, the electrical insulating oil is tempered to the correct temperature for the reaction to proceed. At Box 2, chemicals (from the source of chemicals in Box 3) are added to the oil along with an inert gas and begin to react with the active organosulfur compounds present in the oil. An inert gas is added to the oil to facilitate the reaction between the chemical reagent and the reactive organosulfur compound by keeping volatile reaction products out of the oil phase during t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com