Multipurpose plant for surface treatment of printing material

A technology of printing materials and equipment, which is applied in the field of multi-purpose equipment for surface treatment of single printing materials, can solve the problems of low equipment utilization, high price, and large work space, and achieve high equipment utilization, low processing costs, and equipment investment prices Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

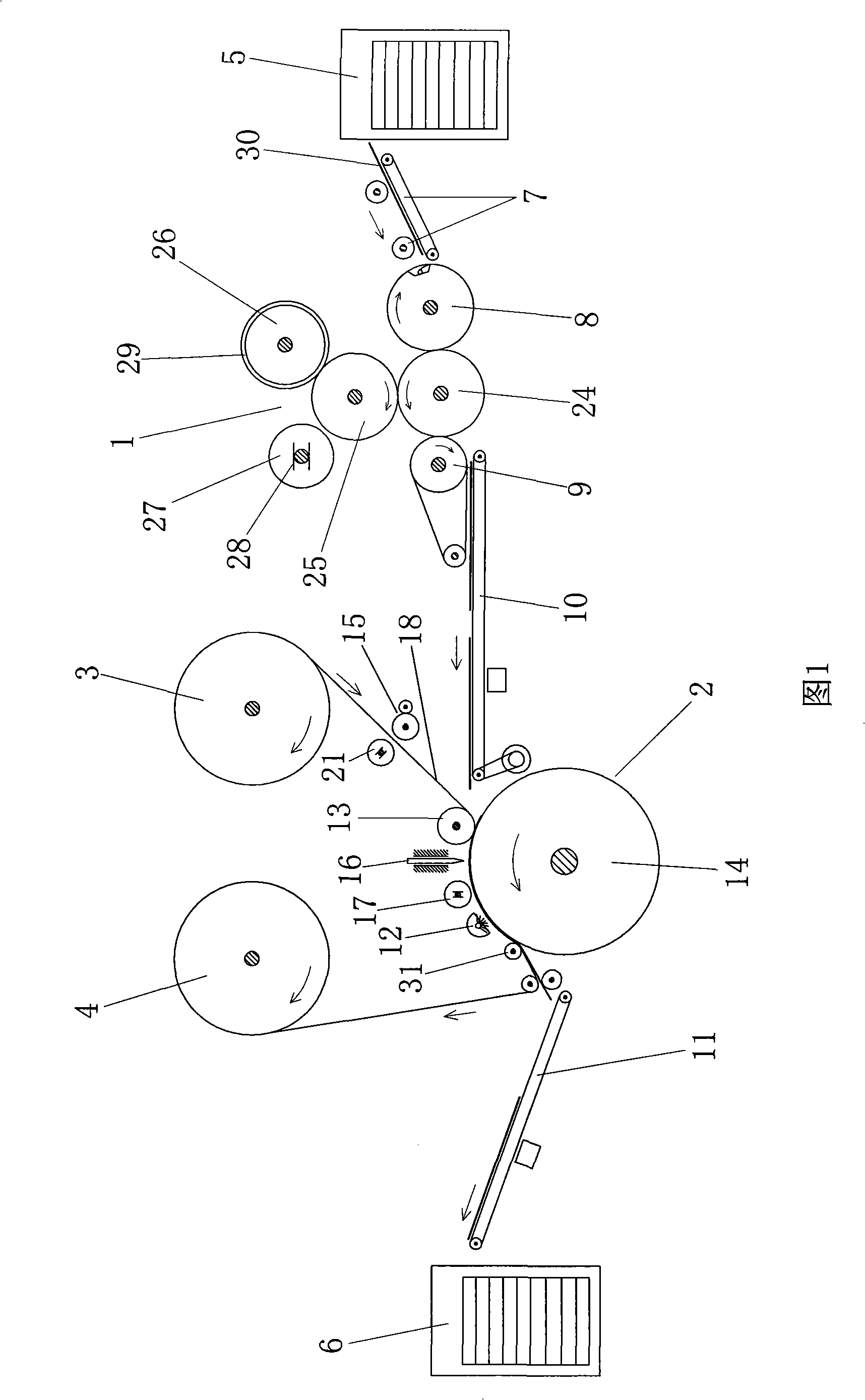

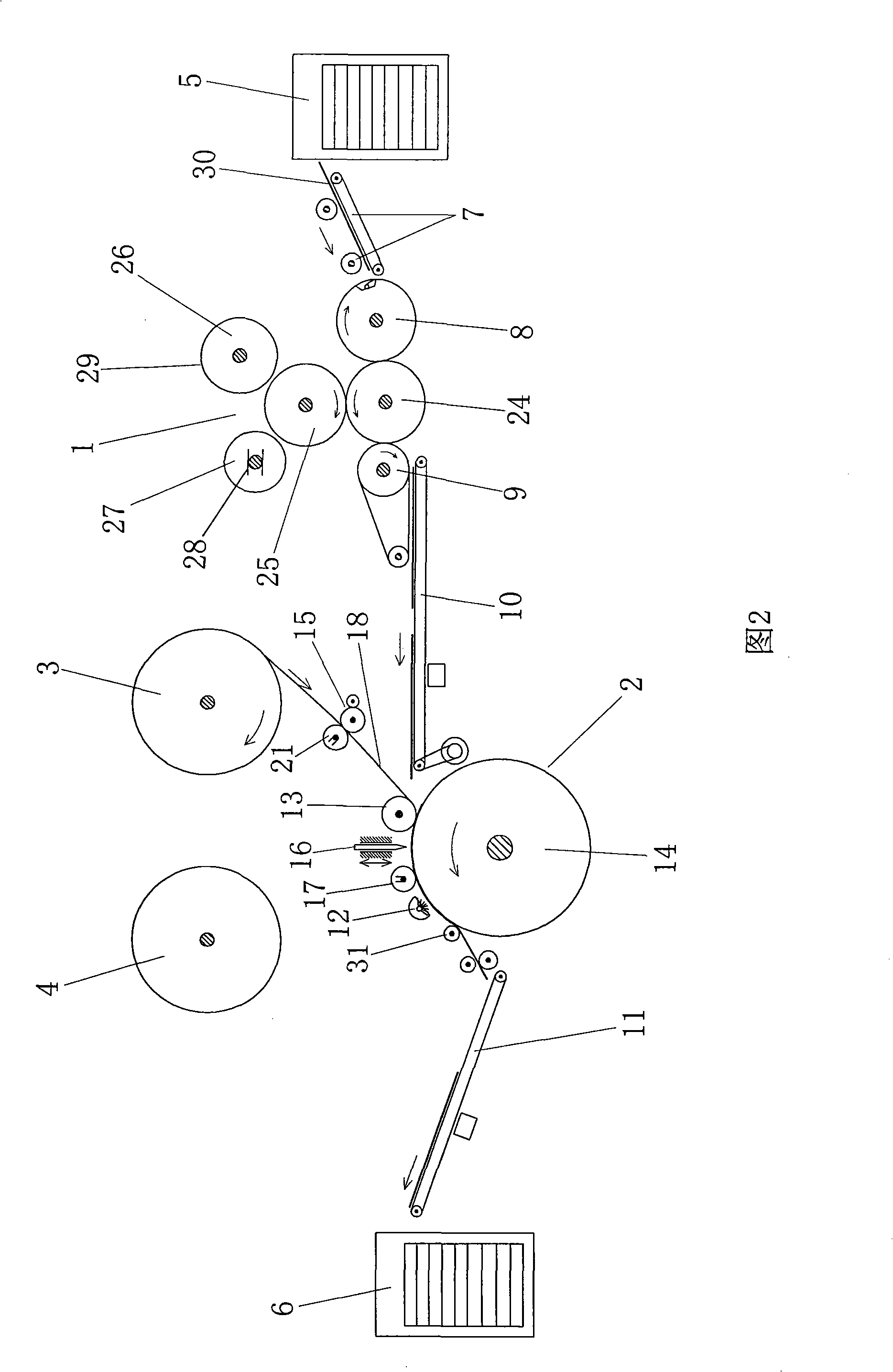

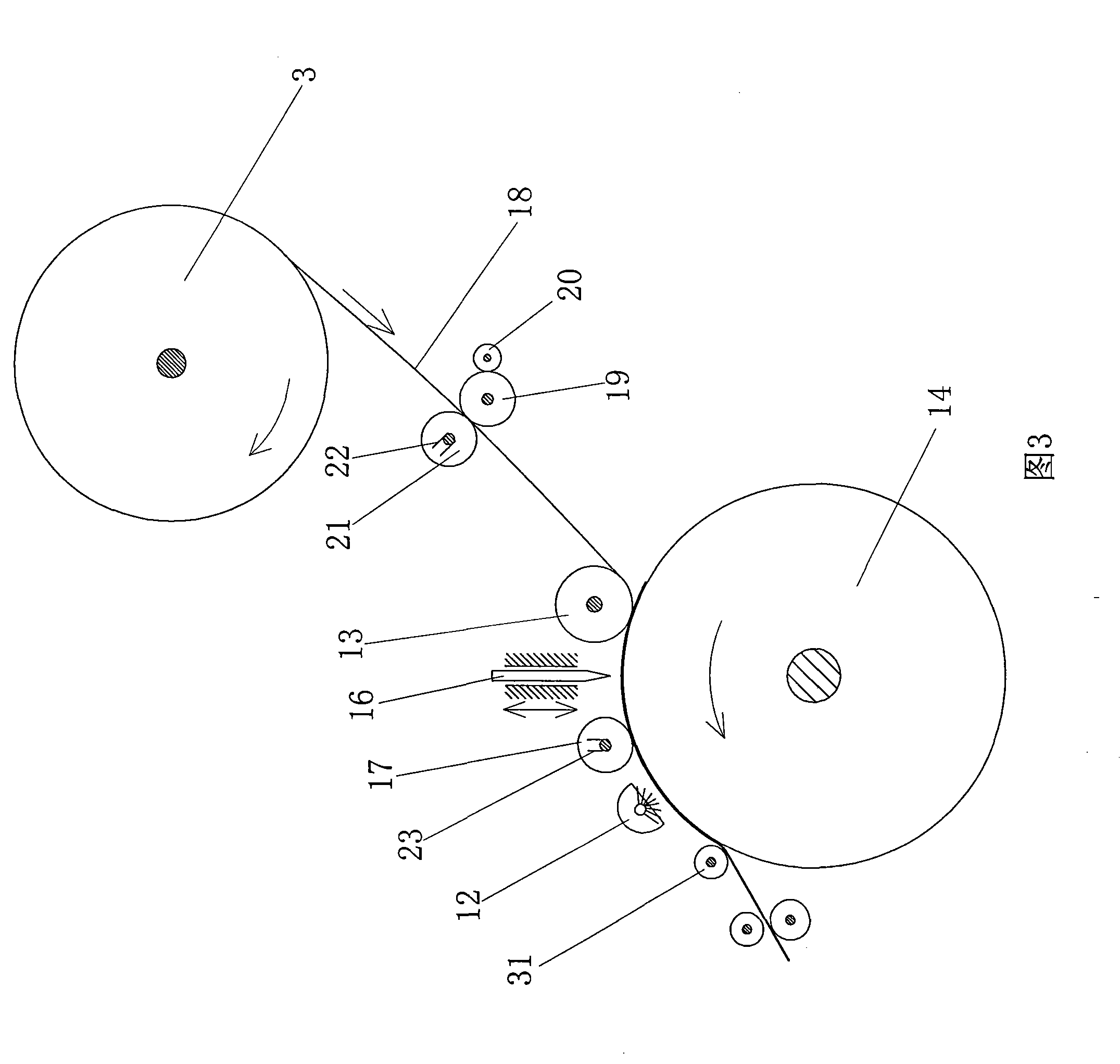

[0020] refer to figure 1 , the equipment that can perform multiple treatments on the surface of printed materials is a multi-purpose system that runs continuously in the direction of the arrow, including a frame (not shown in the figure) and a printing mechanism 1 installed on the frame, and a pressing mechanism 2 , laminating film unwinding mechanism 3, laminating film rewinding mechanism 4, printing material discharging mechanism 5, printed product receiving mechanism 6, several transmission and transmission fixing mechanisms 7, 8, 9, 10, 11, ultraviolet irradiator 12 . Wherein, the printing mechanism 1 is arranged behind the printing material discharging mechanism 5, the laminating mechanism 2 is arranged behind the printing mechanism 1, the laminating film unwinding mechanism 3 and the laminating film rewinding mechanism 4 are arranged near the laminating mechanism 2, and the printing The product receiving mechanism 6 is arranged behind the pressing mechanism 2, and the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com