Bearing rope anchor of cable crane and its construction method

A construction method and technology of load-bearing ropes, applied in the direction of foundation structure engineering, erection/assembly of bridges, sheet pile walls, etc., can solve the problems of limited working surface, narrow construction site, high cost and other problems, and achieve little impact on the surrounding environment , Improve mechanical properties, obvious economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

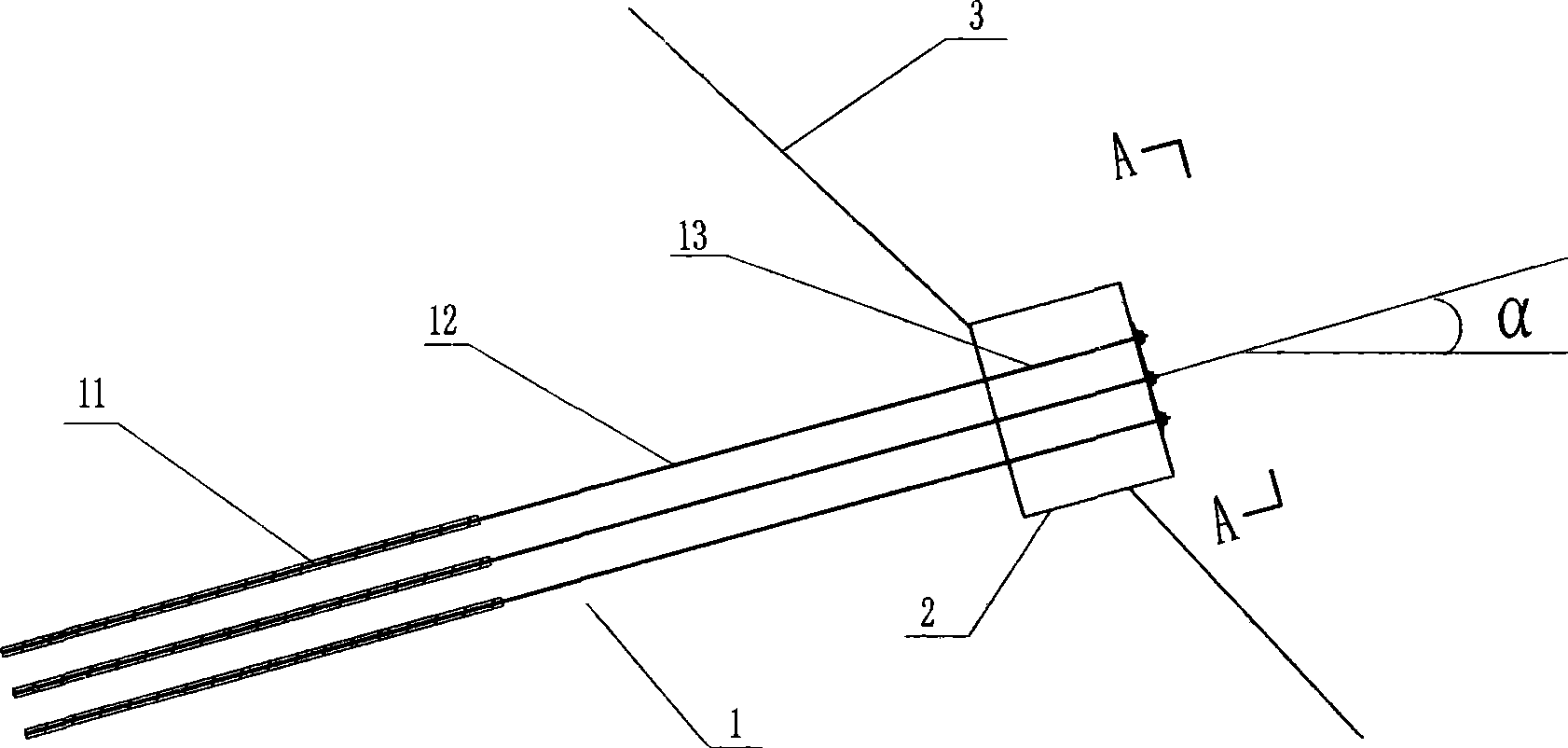

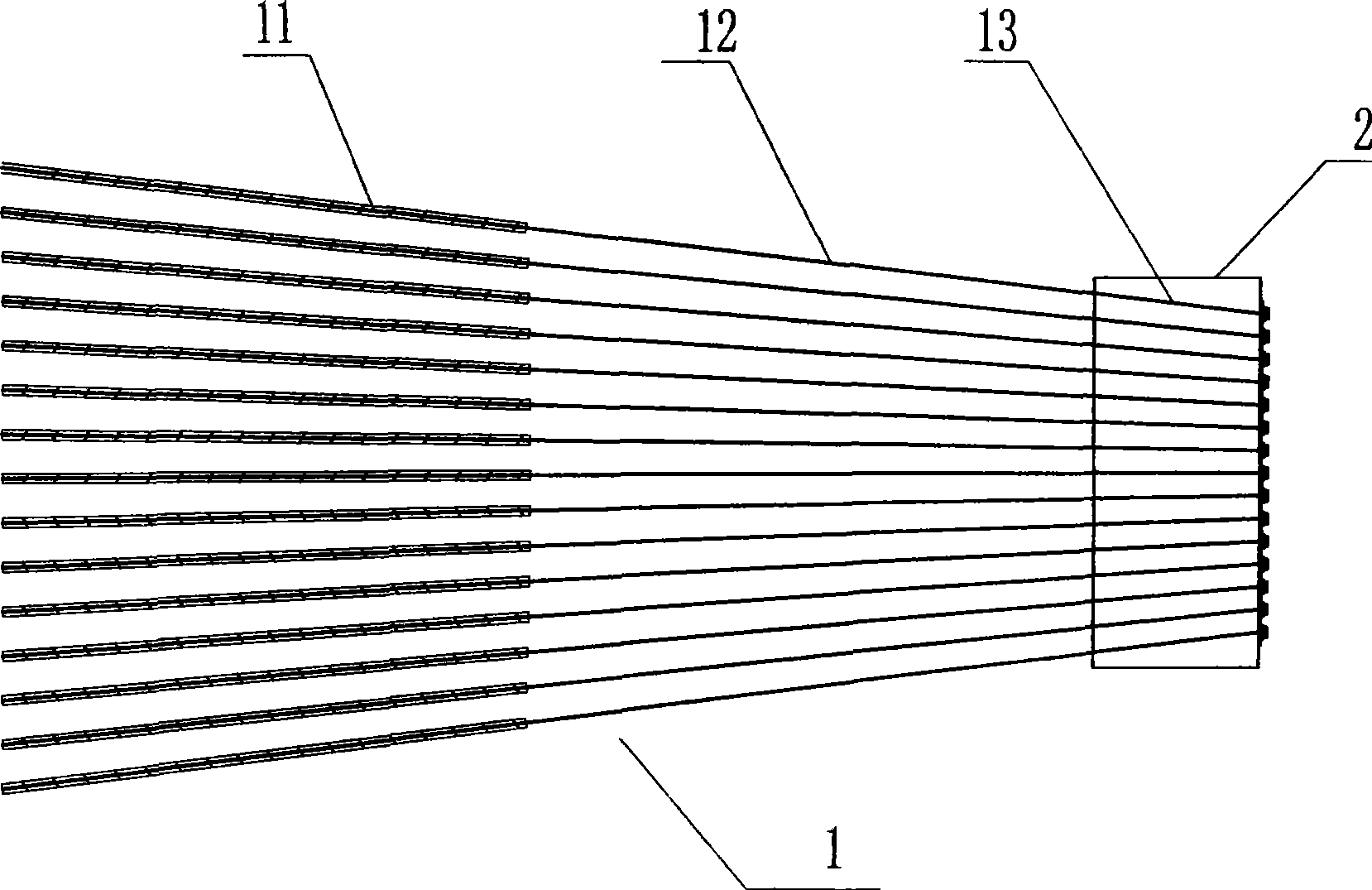

[0025] The ground anchor of the present invention utilizes the rock mass on both sides of the suspension bridge to bear the pulling force of the load-bearing rope of the cable suspension, and adopts a composite structure of prestressed rock anchor + anchor wall. Such as figure 1 with figure 2 As shown, the ground anchor includes a prestressed rock anchor 1 and a reinforced concrete anchor wall 2, wherein the reinforced concrete anchor wall 2 is poured on the rock mass slope 3 on both banks, and the prestressed rock anchor 1 includes an anchor section 11, a free section 12 and an anchor The anchoring section 13 of the wall, the anchoring section 11 is anchored in the rock mass, the anchoring section 13 of the anchoring wall is anchored in the anchoring wall 2, and the free section 13 is in the middle.

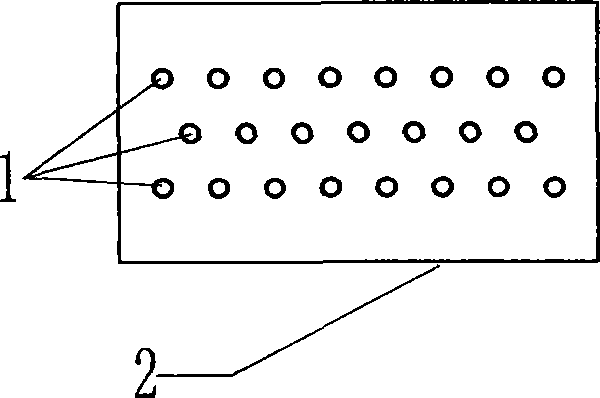

[0026] As a specific embodiment, each ground anchor may include 23 prestressed rock anchors, which are arranged in 3 rows of upper, middle and lower, 8 in the upper row, 7 in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com