Control method for restraining influence of coal mill start/stop to main vapour pressure of boiler

A main steam pressure and control method technology, which is applied in the combustion method, combustion control, and fuel supply adjustment, etc., can solve the fluctuation of parameters such as main steam temperature furnace negative pressure and oxygen content, the main steam pressure fluctuates greatly, and the main steam pressure Fluctuation and other problems, to achieve the effect of improving the quality of parameter control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

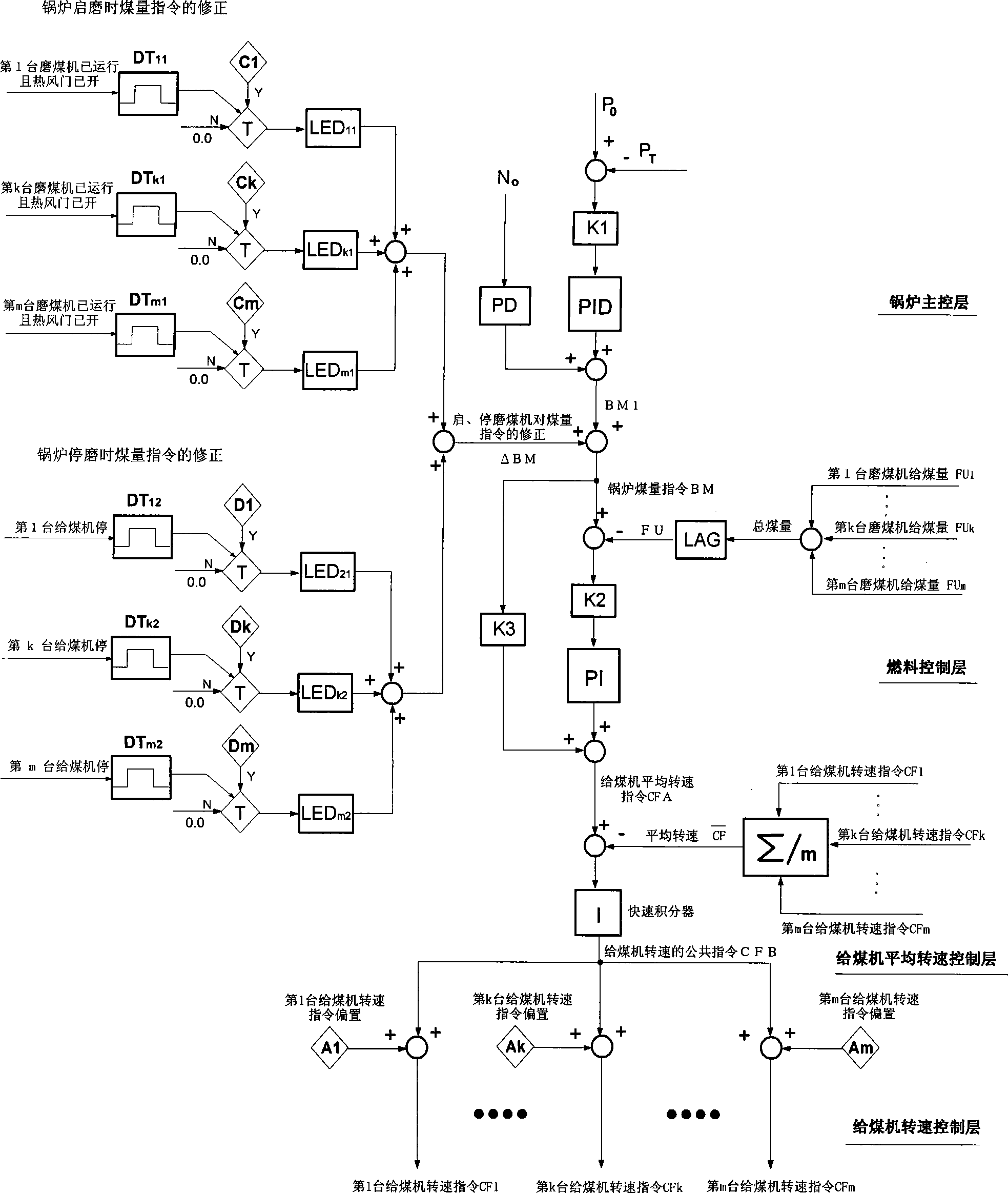

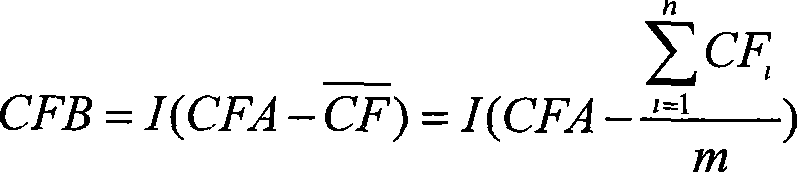

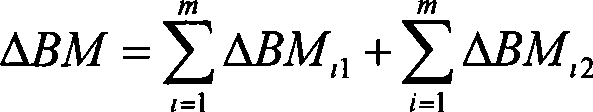

[0039] In this embodiment, a control method for suppressing the influence of starting and stopping the coal mill on the main steam pressure of the boiler adds a fast control layer for the average speed of the coal feeder on the basis of the original three-layer control mode of the boiler fuel, effectively suppressing the In the process of starting or stopping the coal mill, the influence of various operations of the operator on the main steam pressure of the boiler. The dynamic feed-forward technology based on actual differential is also applied to the feed-forward design of the main control system of the boiler, so as to realize the automatic correction of the coal quantity command of the boiler during the process of starting and stopping the coal pulverizer, and to offset the failure caused by the heating and pumping of the grinding mill or the pumping when the grinding is stopped. Part of the amount of pulverized coal that enters the boiler combustion during the pulverizatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com