Heat collection and heat exchange component, solar heat collection plate and solar heat collector

A component and heat collection technology, applied in the field of heat collection and heat exchange components, can solve the problems of heat collection efficiency reduction, material corrosion, increase heat capacity of heat collectors, etc., achieve high heat collection and heat exchange efficiency, reduce production costs, and improve The effect of heat collection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

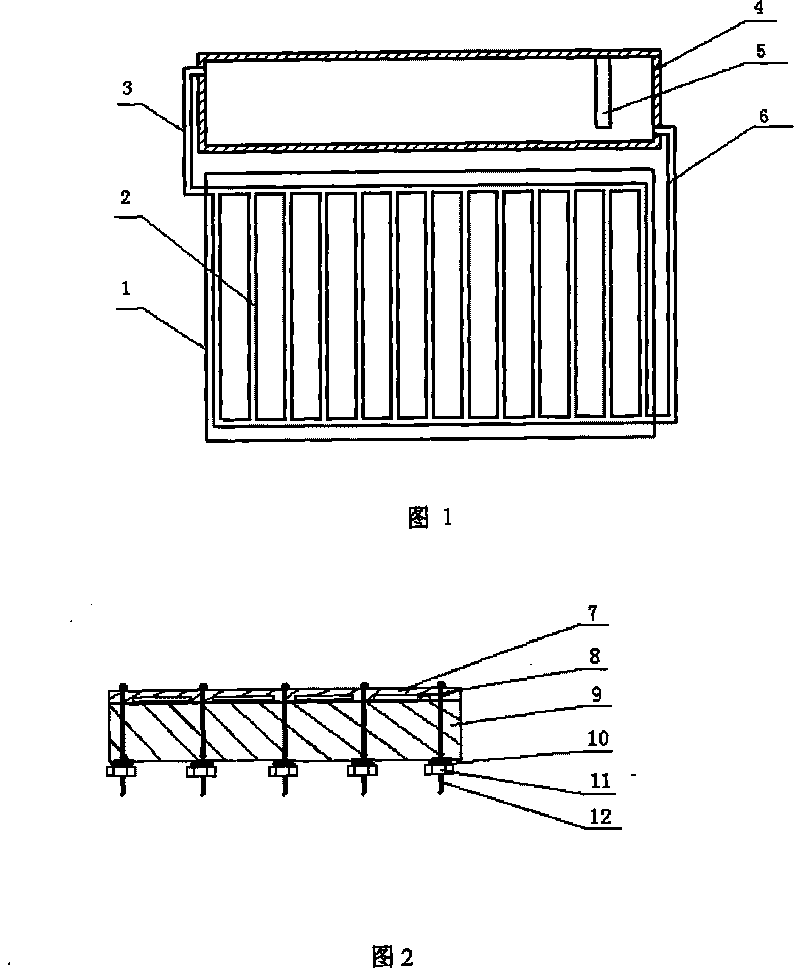

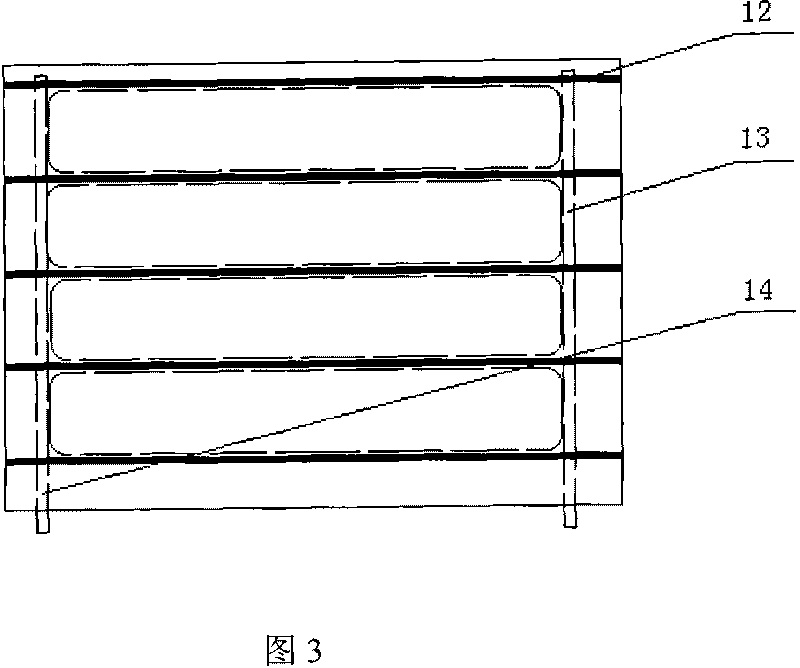

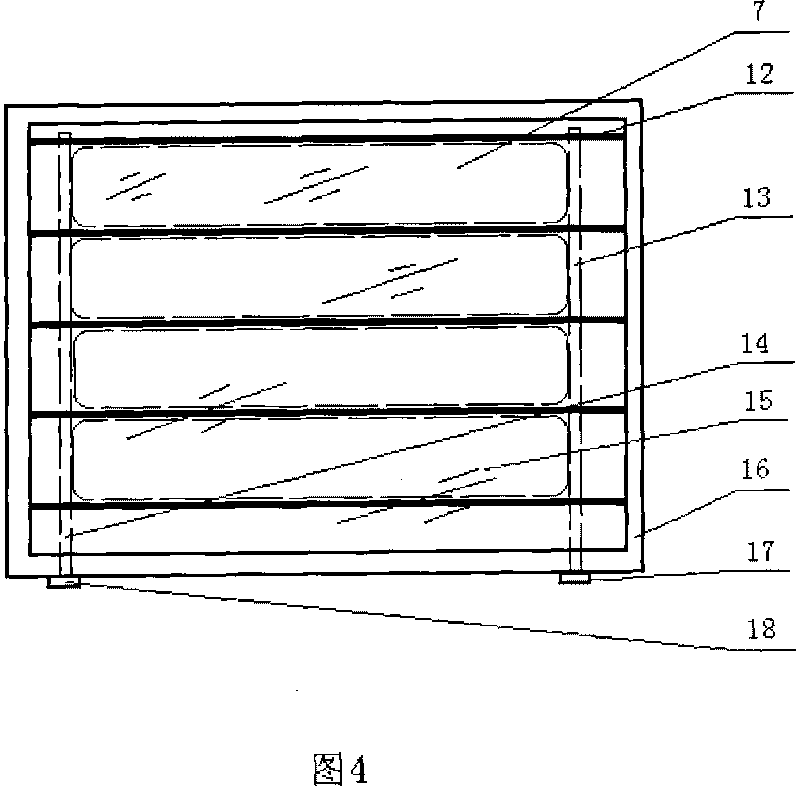

[0023] The present invention will be described in more detail below with reference to the accompanying drawings and embodiments.

[0024] The heat collection and heat exchange member of the present invention includes a pair of plate-shaped members disposed opposite to each other and a fixed sealing structure for fixedly sealing the pair of plate-shaped members, wherein at least one of the pair of plate-shaped members is formed with a concave portion, and the one At least one of the pair of plate-shaped members is made of a thermally conductive material, and when the pair of plate-shaped members is attached together by the fixed sealing structure, the concave portion forms a closed space, and the closed space is provided with at least one inlet and at least one outlet.

[0025] At least one of the pair of plate-like members is formed of a thermally conductive material, and the other is formed of a rigid plate material having a certain flexural strength. Among them, the plate-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com