Patents

Literature

31results about How to "Corrosion resistance is not easy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

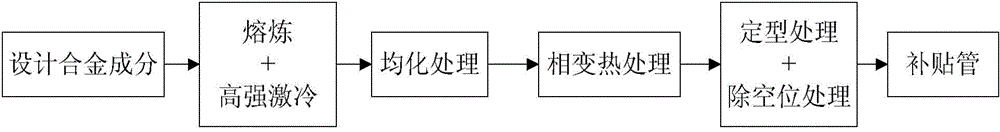

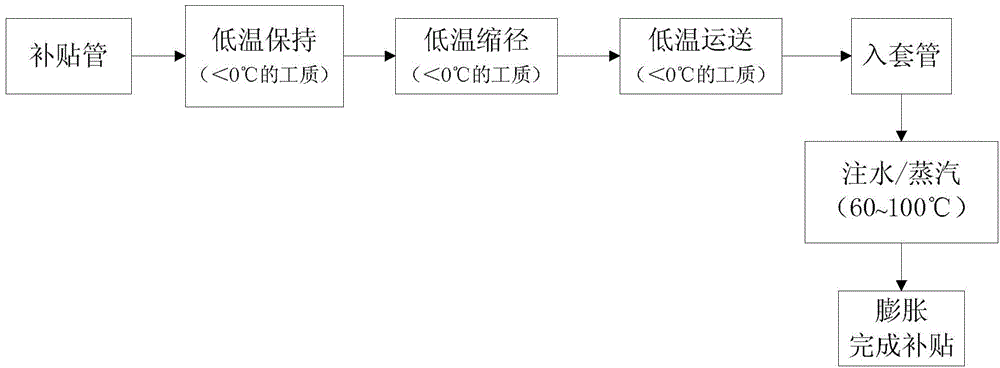

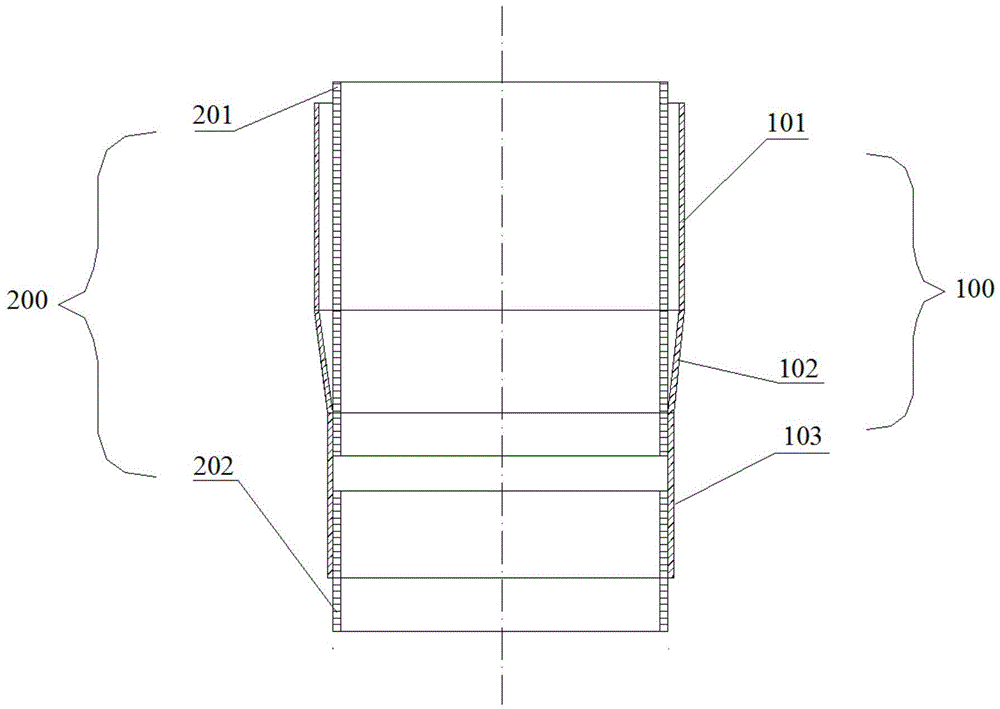

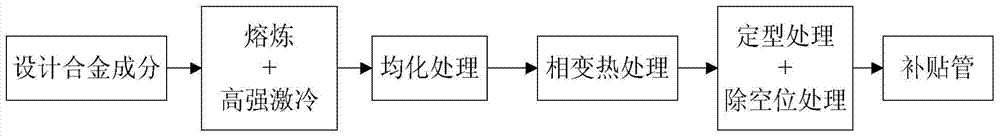

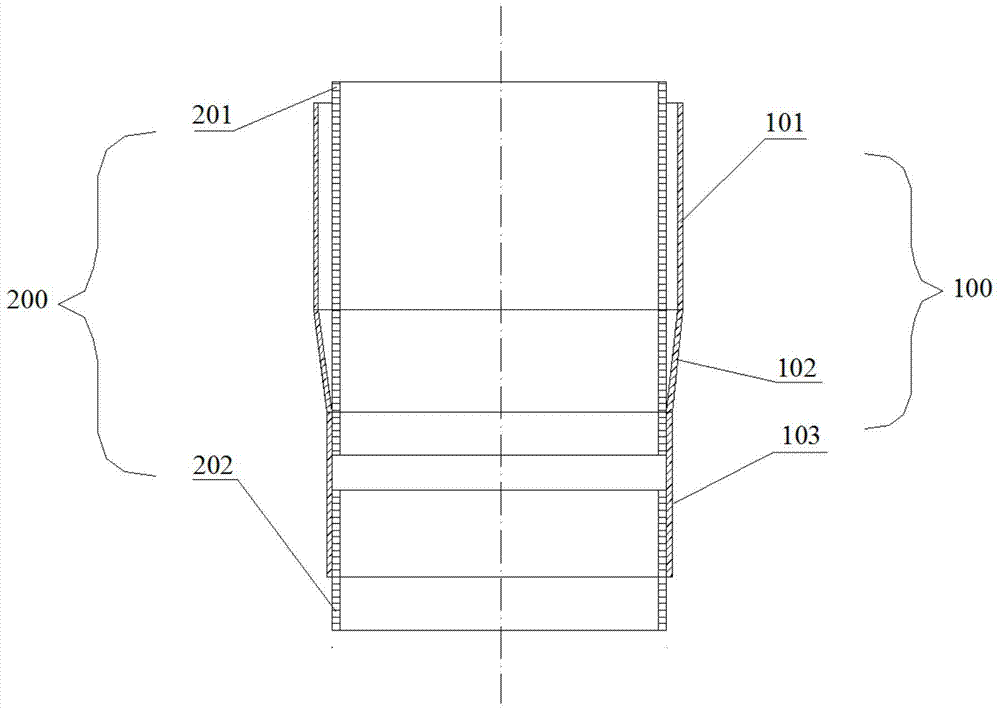

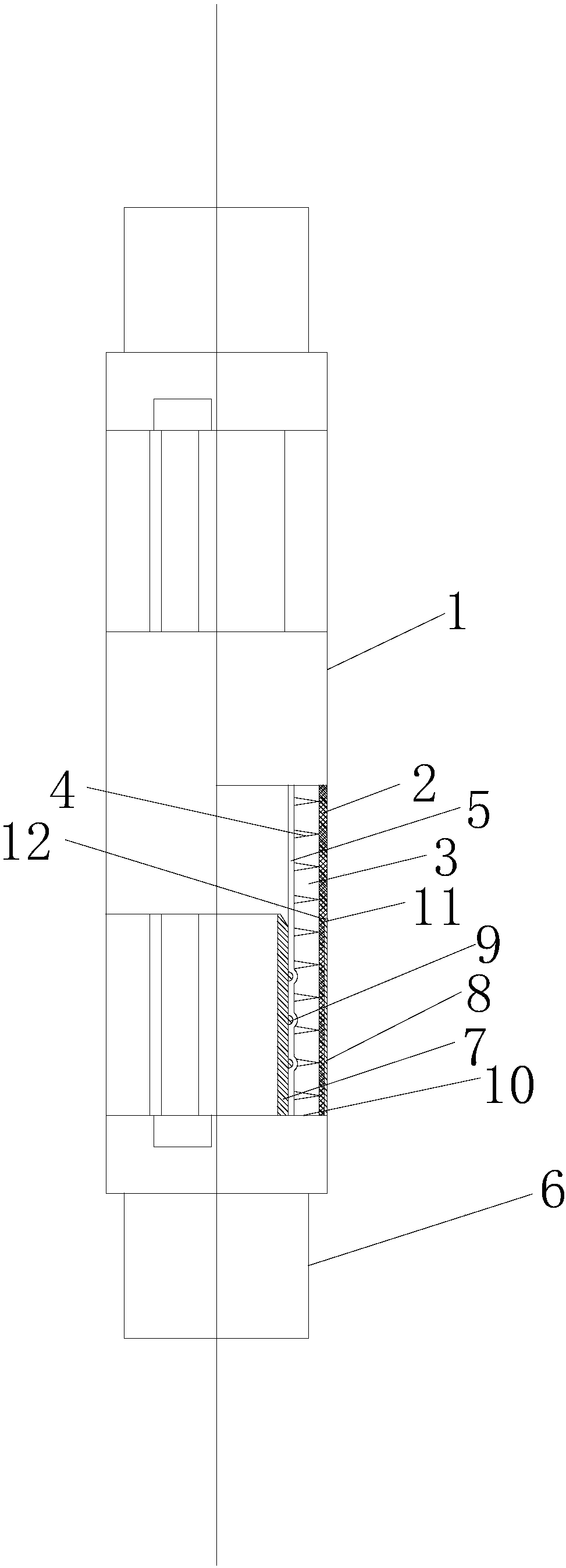

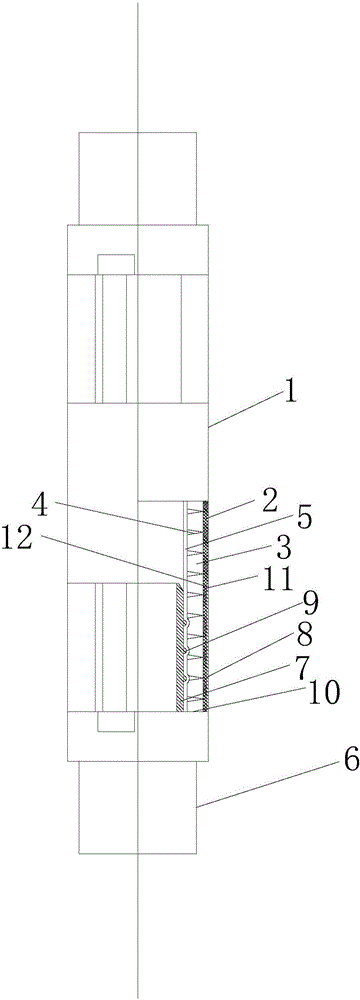

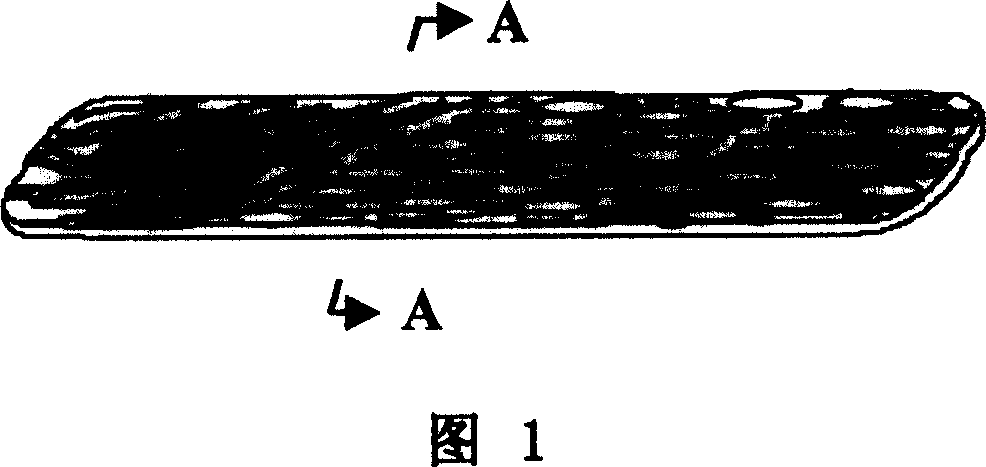

Copper-based memory alloy mended and patched pipe as well as preparation method, mending and patching method and application thereof

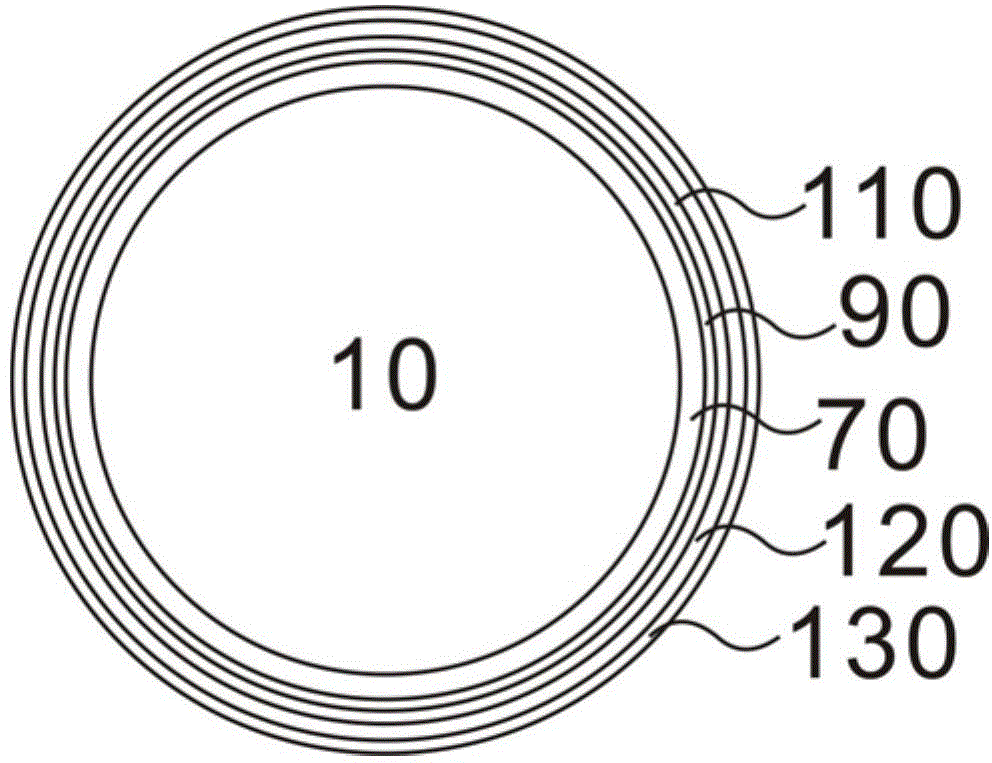

InactiveCN104831112AGood thermoelastic phase transition propertiesLow costBorehole/well accessoriesInterference fitShape-memory alloy

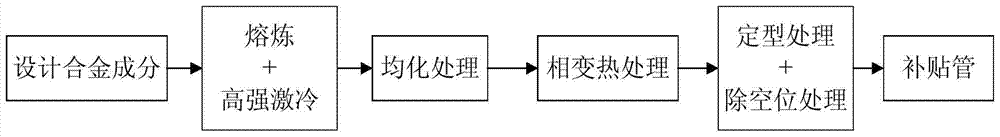

The invention provides a copper-based memory alloy mended and patched pipe as well as a preparation method, mending and patching method and application thereof. A copper-based memory alloy comprises the following elements by mass percent: 0.2-1.6% of Be, 6-14% of Al, 1-10% of Mn, 0-3% (more than 0) of Ga, 0-0.1% of impurities and the balance of Cu. The mended and patched pipe is formed by connecting an expansion component with connecting pipes, wherein the expansion component comprises an expanded cylinder, a conical connector and an internally threaded cylinder, which are connected with each other in sequence. The preparation method comprises the following steps: weighing the raw materials according to the alloy components, smelting the raw materials and then cooling the product in a directional solidification cooling system to prepare a cast ingot; then carrying out thermal mechanical treatment, thus obtaining the mended and patched pipe. The mended and patched pipe is simple in mending and patching process and can be in powerful interference fit with a casing to be mended and patched, thus generating great sealing pressure and friction between the mended and patched pipe and the casing and preventing oil leak and fall.

Owner:无锡源创机械科技有限公司

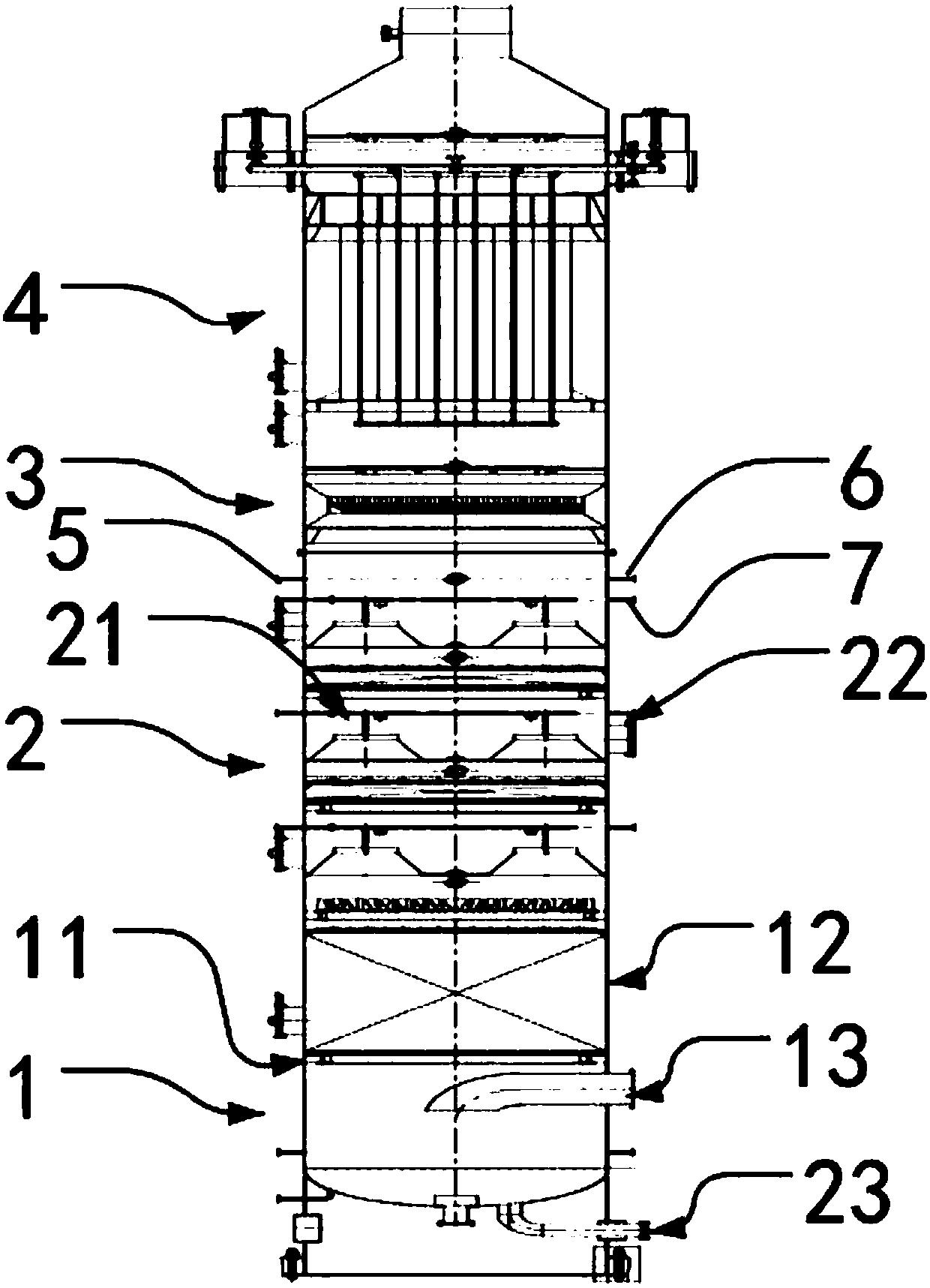

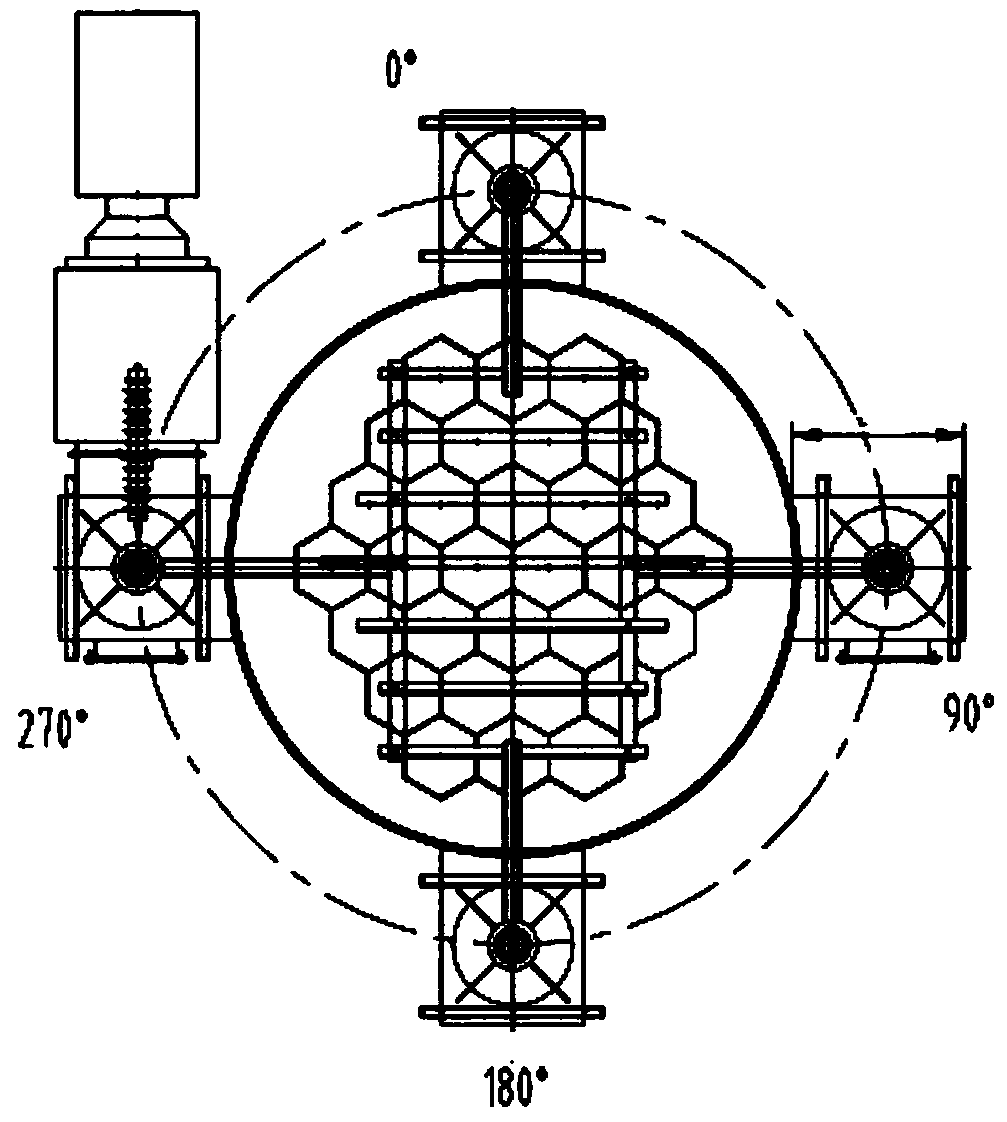

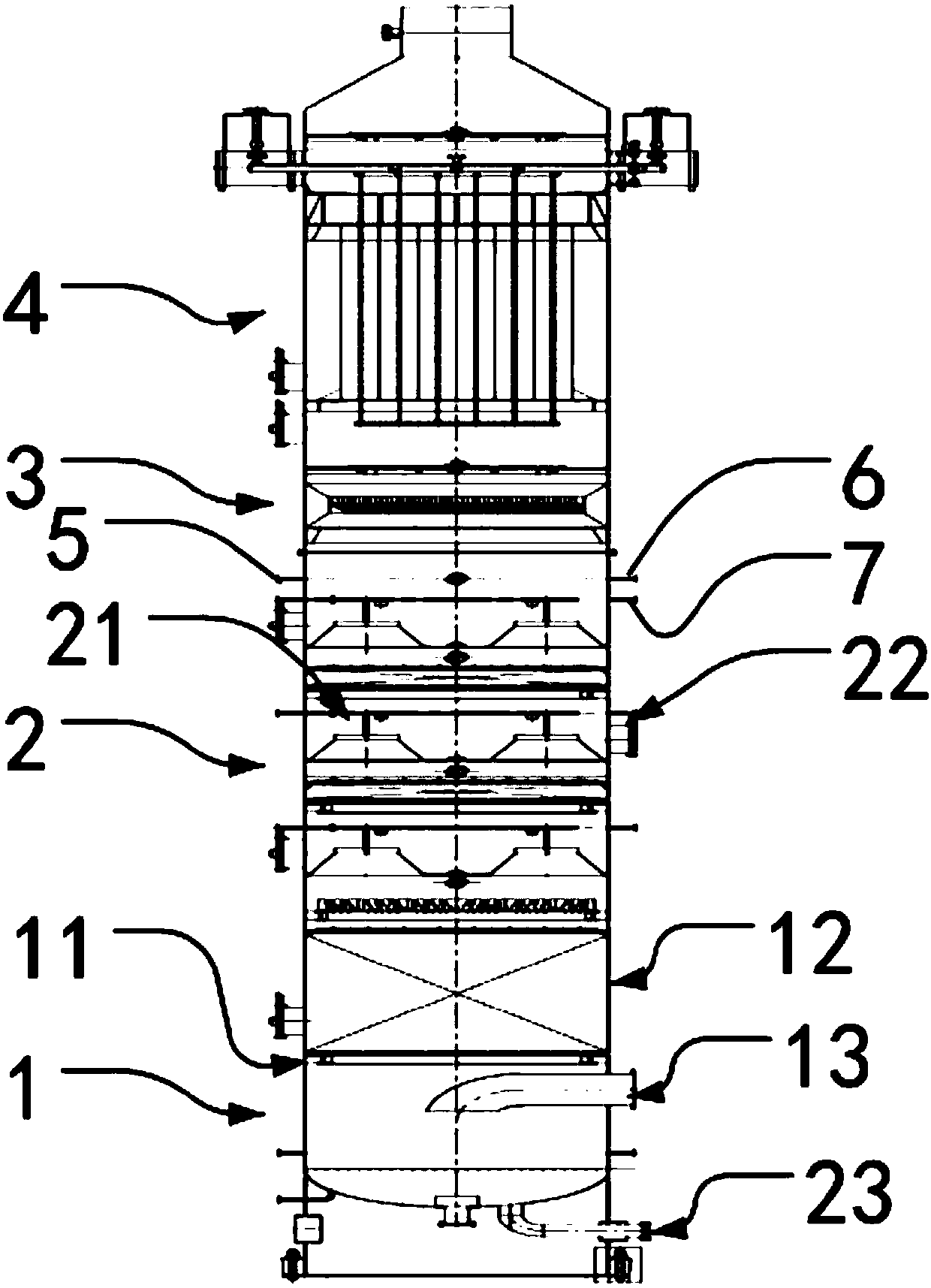

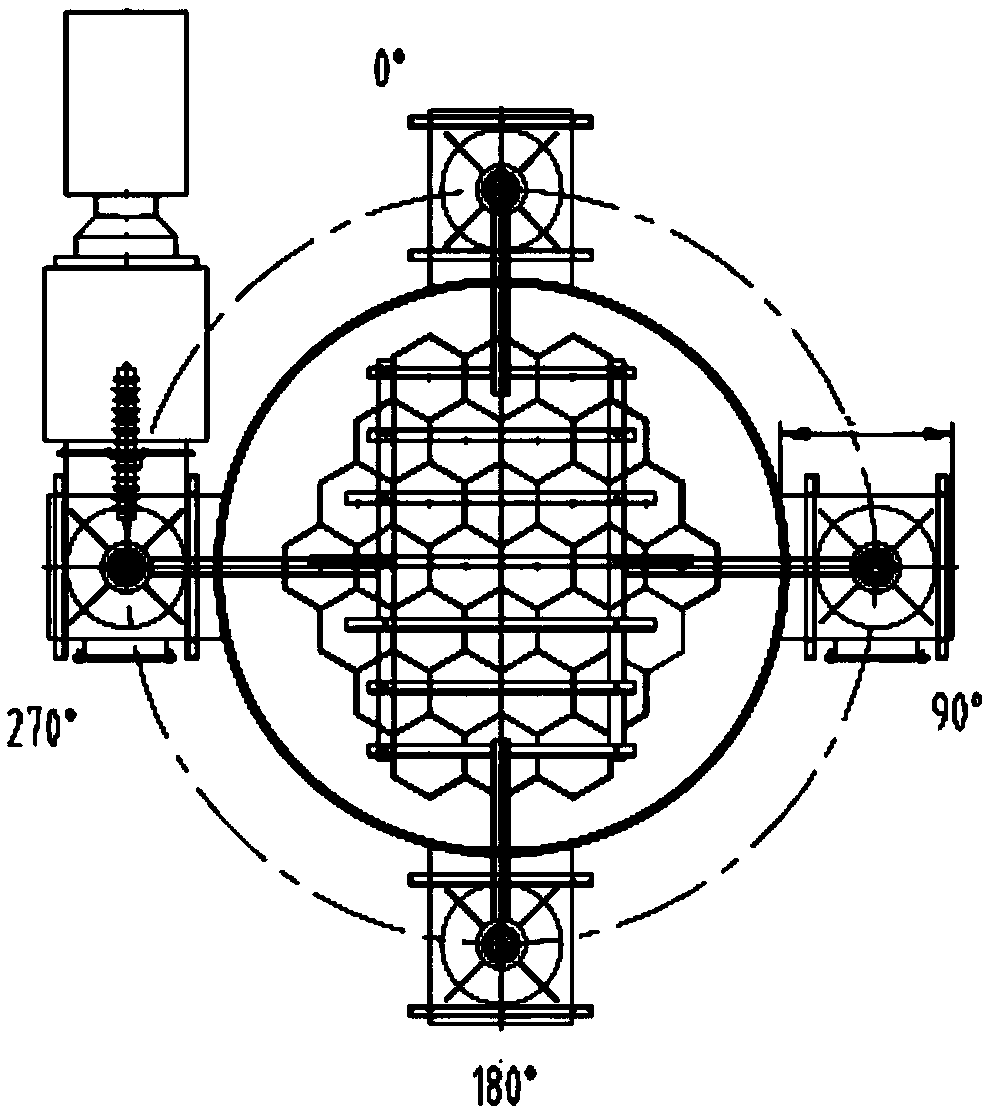

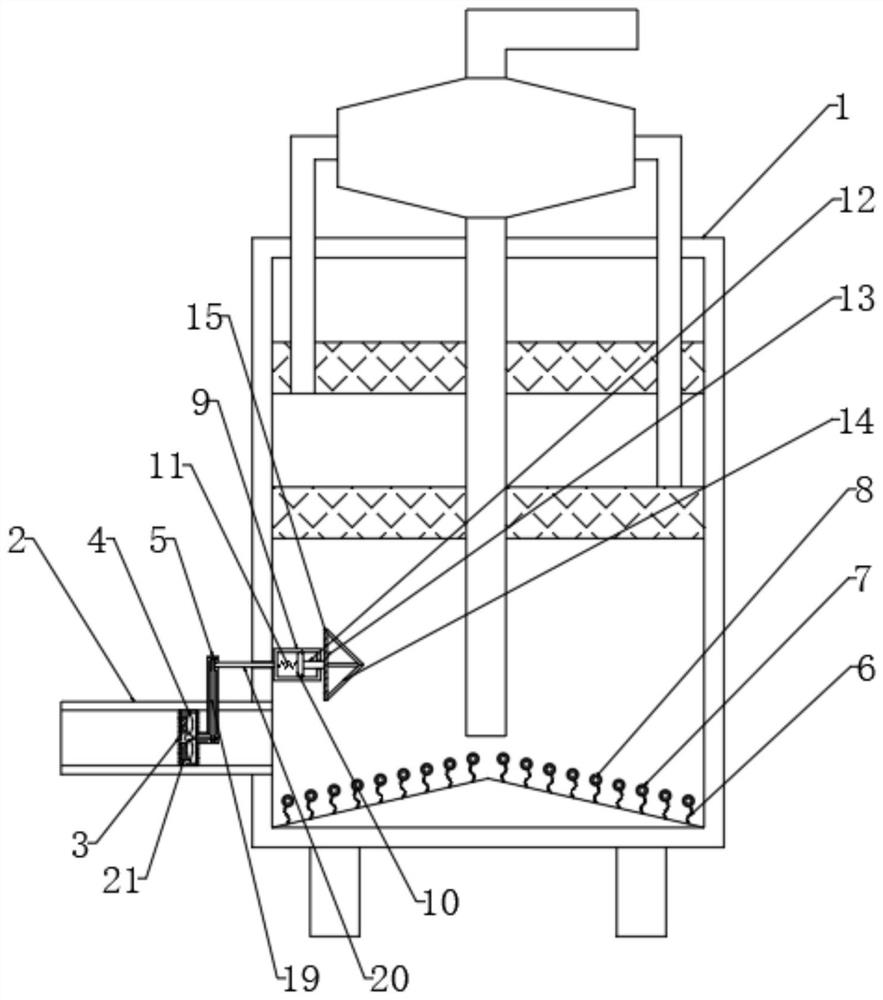

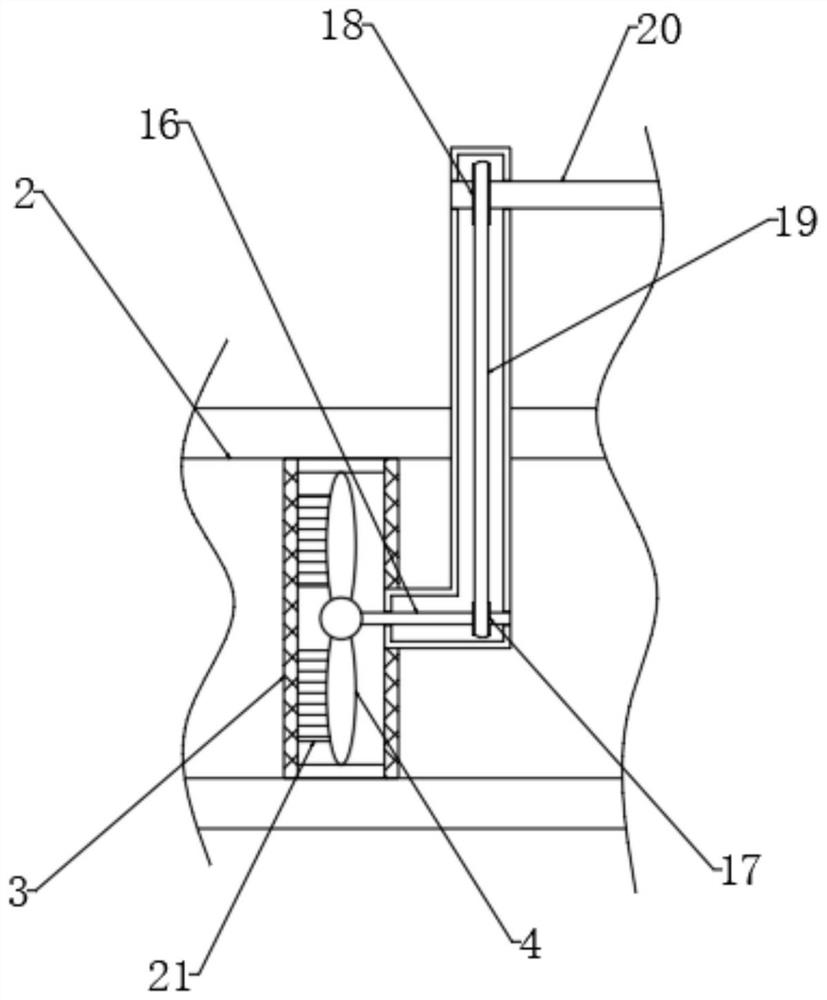

Low-temperature waste heat treatment equipment for dried tail gas

InactiveCN107606928AAchieve emission standardsMaximize the recycling processCombination devicesDrying solid materialsHeat pumpFlash evaporation

The invention discloses low-temperature waste heat treatment equipment for dried tail gas. The low-temperature waste heat treatment equipment comprises a tail gas treatment chamber, wherein the tail gas treatment chamber is sequentially equipped with a vacuum flash-evaporation section, a spraying and heat-collecting section, an atomizing and dust-collecting section and an electrostatic dust-collecting section from bottom to top; tail gas enters the spraying and heat-collecting section, heat is enriched by circulating water, the circulating water enters the vacuum flash-evaporation section to generate negative-pressure steam, and the negative-pressure steam is used as a heat source of a vacuum heat pump in the vacuum flash-evaporation section; and after the circulating water is cooled through flash-evaporation treatment, the circulating water is conveyed through the vacuum heat pump and is circulated, cooled tail gas sequentially enters the atomizing and dust-collecting section and theelectrostatic dust-collecting section for being further subjected to dust collection, and part of tail gas which passes through the electrostatic dust-collecting section is introduced into the spraying and dust-collecting section.

Owner:苏州卓润赛豚节能环保科技有限公司

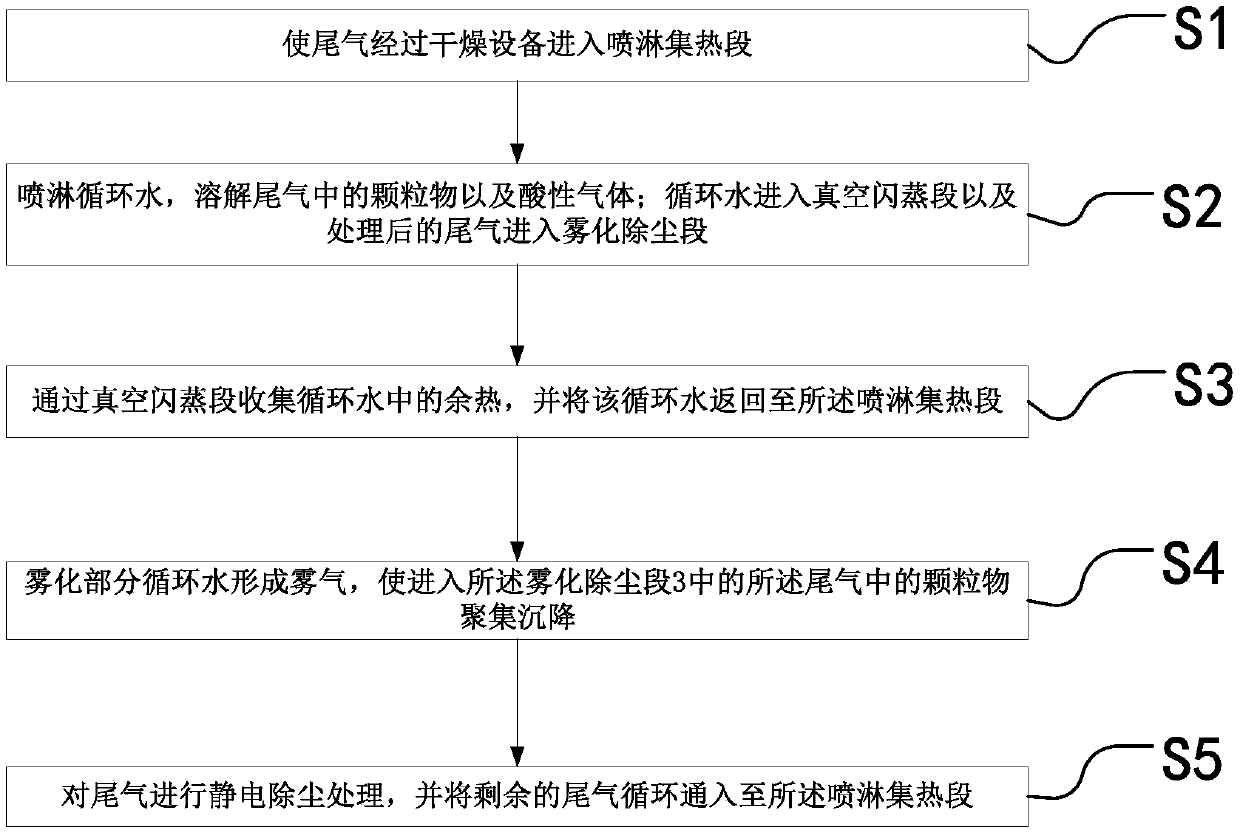

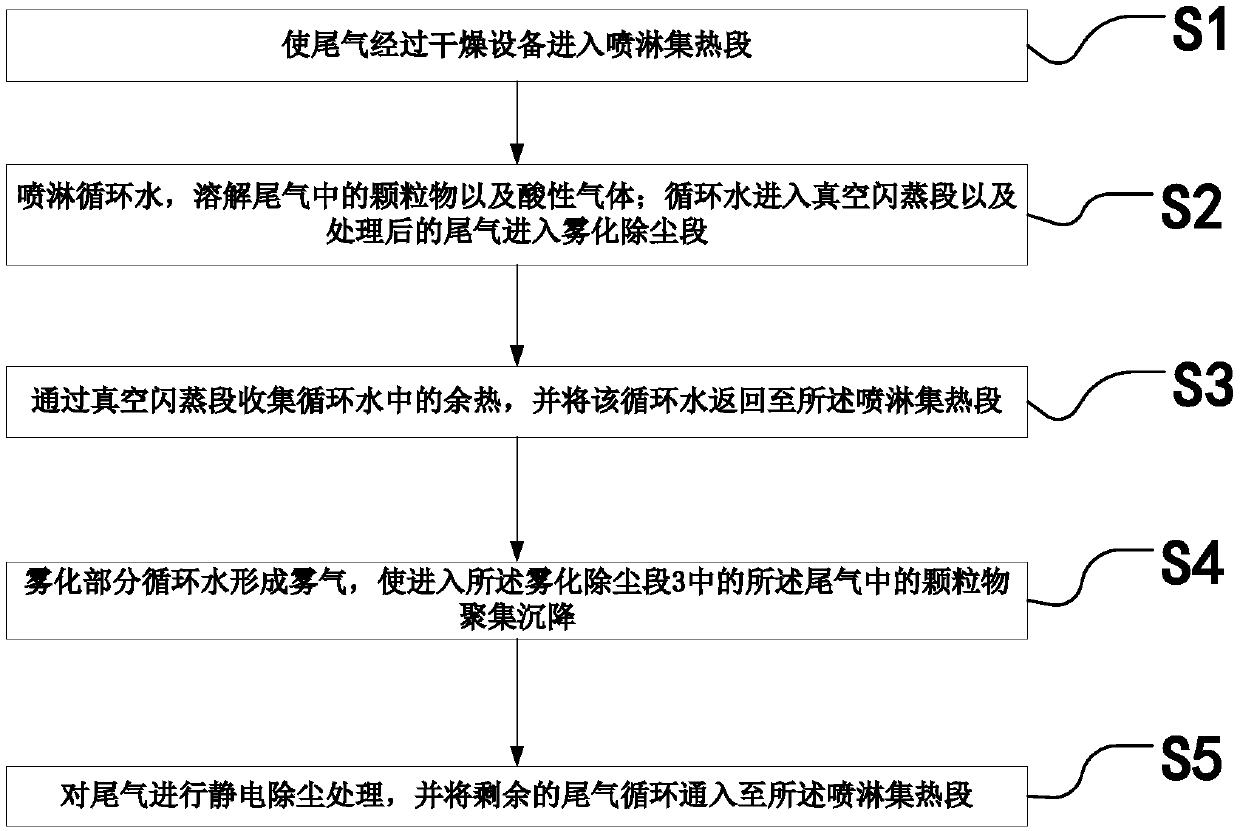

Low-temperature waste heat treatment method for dry tail gas

InactiveCN107726831AAchieve emission standardsGuaranteed emission standardsCombination devicesHeat pumpsParticulatesEnvironmental engineering

The invention discloses a low-temperature waste heat treatment method for dry tail gas. The low-temperature waste heat treatment method comprises the following steps that S1, tail gas passes through drying equipment to go into a spraying heat collection section; S2, circulating water is sprayed to dissolve particulate matter and acid gas in the tail gas and goes into a vacuum flashing section, andthe treated tail gas goes into an atomization dust removal section; S3, waste heat of the circulating water is collected through the vacuum flashing section, and the circulating water is returned tothe spraying heat collection section; S4, part of the circulating water is atomized to form mist to make the particulate matter in the tail gas going into the atomization dust removal section gather and settle, and the treated tail gas goes into an electrostatic dust collection section; and S5, the tail gas is subjected to electrostatic dust collection treatment, and the remaining tail gas is cyclically introduced to the spraying heat collection section.

Owner:苏州卓润赛豚节能环保科技有限公司

A kind of graphene organic silver conductive ink and preparation method thereof

The invention discloses a graphene organic silver conductive printing ink and a preparation method thereof. The conductive printing ink comprises a conductive function unit precursor, an organic silver complexing agent, an adhesive, a solvent and auxiliaries. The preparation method comprises the following steps: (A) stirring and ultrasonically dispersing the organic silver, the solvent and the organic silver complexing agent under a lucifugal condition to obtain an organic silver complexing solution; and (B) putting the graphene, the resin adhesive, the auxiliaries and the organic silver complexing solution in the lucifugal condition and stirring and ultrasonically dispersing in an environment lower than 10 DEG C, wherein the obtained uniform mixture is the graphene organic silver conductive printing ink. The graphene organic silver conductive printing ink prepared by the method disclosed by the invention is low in solid content, good in stability, good in printing performance and wide in application.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Isolated axial flow pump blade

InactiveCN103899571AStrong weather resistanceCorrosion resistance is not easyPump componentsPumpsImpellerCorrosion

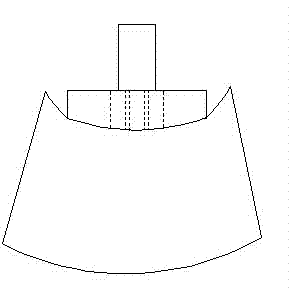

The invention discloses an isolated axial flow pump blade which comprises a blade body. The isolated axial flow pump blade is characterized in that the blade body is a disc-shaped connection part, one face of a disc is of a spiral blade structure and the other face of the disc is of a cylinder axis structure. The blade body is formed in an injection molding mode and made of thermosetting resin nanocomposite. The outer face of the blade body is coated with an ultra high molecular weight polyethylene layer. The shortcomings of the prior art are overcome, the designed structure is reasonable, the blade and an impeller shaft can be detached, the number of blades is freely chosen, and the material is the nanometer polymer composite material which is resistant to corrosion and high in weather fastness. The isolated axial flow pump blade is not prone to corrosion, and capable of ensuring the good working performance, prolonging the service life and greatly reducing fees in maintaining and replacing the blade of the impeller.

Owner:安徽华瑞塑业有限公司

Wear-resistant corrosion-resistant enamel glaze with good adhesive force

ActiveCN103723922AGood wear resistance and corrosion resistanceNot easy to fall offCorrosion resistantPOLYETHYLENE WAX

The invention discloses wear-resistant corrosion-resistant enamel glaze with a good adhesive force. The wear-resistant corrosion-resistant enamel glaze comprises the following components by mass: 8-9 parts of micaceous, 1 part of sodium pyrophosphate, 6 parts of lithium oxide, 7 parts of boric anhydride, 4 parts of cobaltous oxide, 3 parts of barium oxide, 6 parts of aluminium oxide, 6-8 parts of feldspar, 4 parts of calcium oxide, 8 parts of sodium oxide, 8 parts of polyethylene wax powder, 7 parts of calcium fluoride, and 10-15 parts of quartz. The enamel glaze provided by the invention cannot fall off easily, and is wear-resistant and corrosion-resistant.

Owner:得宝搪瓷(中山)有限公司

Corrosion resistant ethylene propylene diene monomer rubber

The invention provides a corrosion resistant ethylene propylene diene monomer rubber and relates to the technical field of high polymer materials. The corrosion resistant ethylene propylene diene monomer rubber contains the raw materials of 80-100 parts of ethylene propylene diene monomer rubber, 18-25 parts of polytetrafluoroethylene, 15-23 parts of butyl rubber, 11-16 parts of fluororubber, 7-13 parts of chloroprene rubber, 20-25 parts of CR232 type chloroprene rubber, 5-11 parts of glass, 8-13 parts of wax candles, 14-19 parts of titanium silicon, 7-11 parts of monel 400 alloys, 12-18 parts of 316 stainless steel, 15-22 parts of carbon monofluoride, 5-9 parts of a bactericide, 10-14 parts of a filler, and 12-16 parts of a fire retardant. The corrosion resistant ethylene propylene diene monomer rubber provided by the invention has the advantages of low raw material price, simple making process, good corrosion resistant effect of the prepared ethylene propylene diene monomer rubber and long service life.

Owner:佛山市高明区生产力促进中心

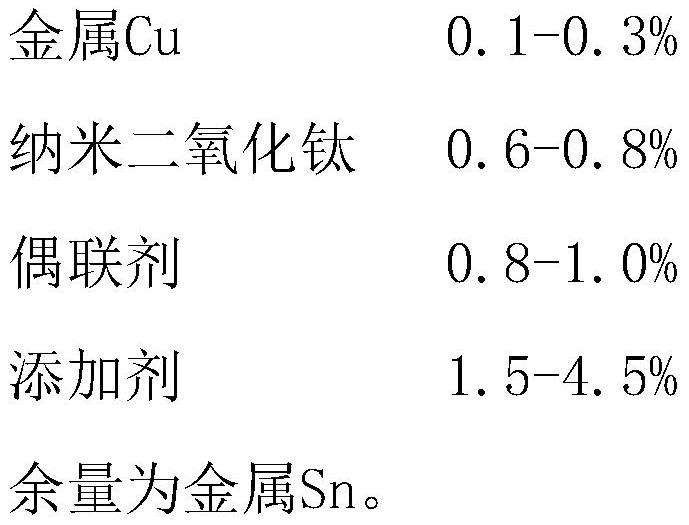

Copper-clad steel tinned wire and preparation process thereof

ActiveCN112071470ANovel structureHigh strengthSingle bars/rods/wires/strips conductorsAuxillary non-insulated conductorsTinningWire rod

The invention relates to the technical field of wires, in particular to a copper-clad steel tin-plated wire and a preparation process thereof. The copper-clad steel tin-plated wire sequentially comprises a core layer, a copper layer and a tin-plated layer from inside to outside, and the thickness of the tin-plated layer is 1-3 micrometers; the preparation method of the copper-clad steel tin-platedwire comprises the following steps: A, pulling a steel wire; b, electroplating a copper layer; c, performing wire drawing and annealing treatment; d, cooling and performing air-drying treatment; ande, performing tinning treatment. The copper-clad steel tin-plated wire is novel in structure, simple in preparation process operation and easy to control, the prepared wire is high in strength, the tin-plated layer is stabilized on the basis that the high-strength copper-clad steel wire is prepared, protection on the copper layer is improved, the oxidation resistance of the wire is improved, the copper layer is not prone to oxidation discoloration or corrosion, and the service life of the wire is prolonged; and practicality is high.

Owner:东莞市凯兴金属材料有限公司

Carbon oil and preparation method thereof

InactiveCN110564218AImprove high temperature resistanceImprove conductivityInksElectrical resistance and conductanceSolvent

The invention relates to the technical field of conductive ink, and discloses carbon oil which comprises poly(3,4-ethylenedioxythiophene)-poly(styrenesulfonate), acetylene black, graphene, hydroxypropyl cellulose, copper nanoparticles and a solvent. The invention also provides a preparation method of the carbon oil. A carbon oil printing product provided by the invention has the advantages of small resistance, high temperature resistance and long service life; and the carbon oil has good uniformity and adhesive force.

Owner:益阳市明正宏电子有限公司

A copper-based memory alloy subsidized tube and its preparation method, subsidized method and use

InactiveCN104831112BGood superelasticityIncreased maximum deformationBorehole/well accessoriesInterference fitIngot

The invention provides a copper-based memory alloy subsidized pipe and its preparation method, subsidized method and application. The copper-based memory alloy includes the following elements in terms of mass percentage: Be: 0.2-1.6%, Al: 6-14%, Mn: 1-10%, Ga: 0-3% and 0 is not included, and impurities: 0-10%. 0.1%, the balance is Cu. The auxiliary pipe is formed by connecting an expansion assembly and a connecting pipe; wherein, the expansion assembly includes an expansion cylinder, a conical connection body and an internal thread cylinder connected in sequence. The preparation method is as follows: taking raw materials according to the alloy composition and melting them, then cooling in a directional solidification cooling system to obtain ingots, and then performing thermomechanical treatment to obtain subsidized pipes. The subsidized pipe has a simple subsidizing process, and it can generate a strong interference fit with the casing to be subsidized, thereby generating a large sealing pressure and friction with the casing to prevent oil leakage and falling.

Owner:无锡源创机械科技有限公司

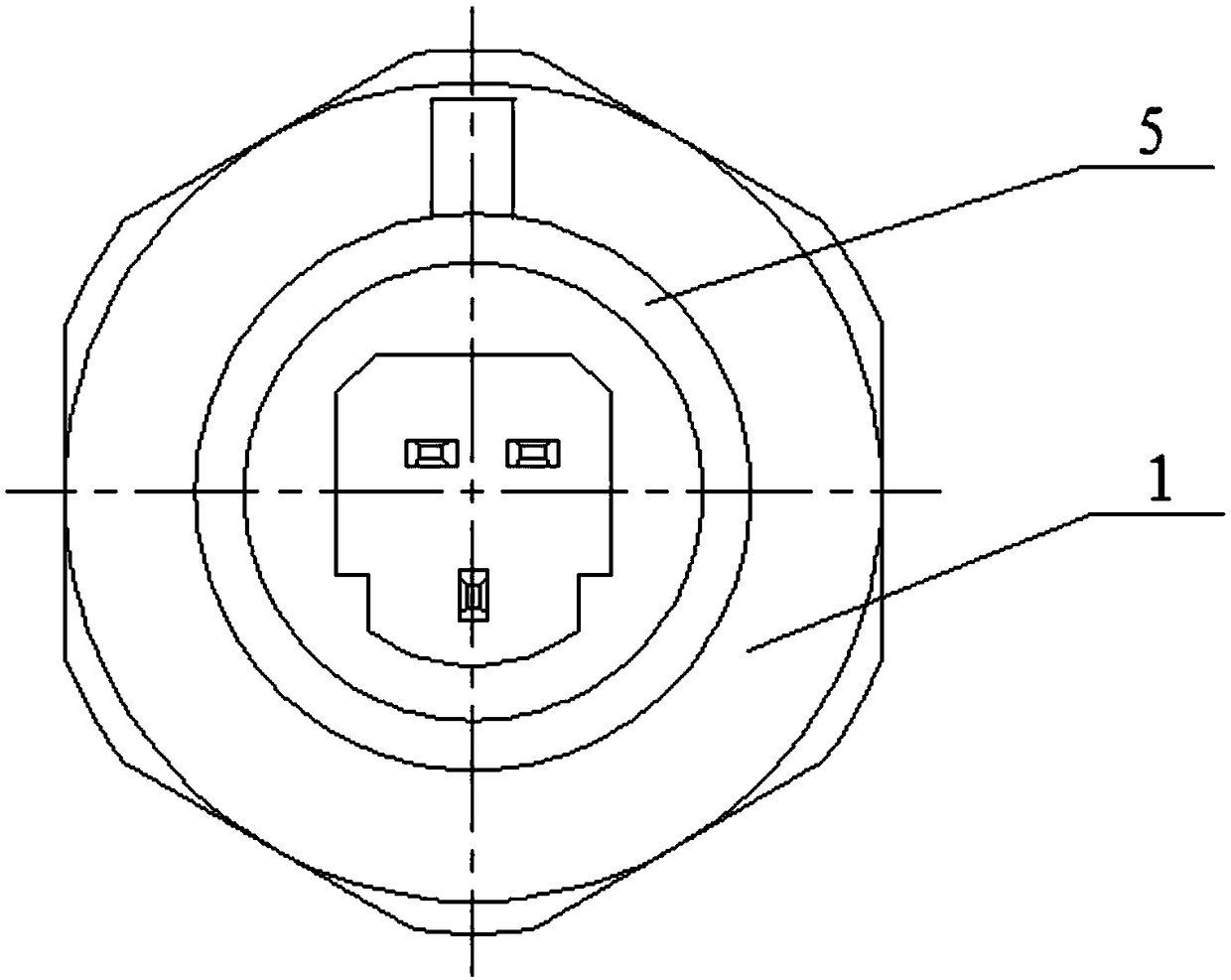

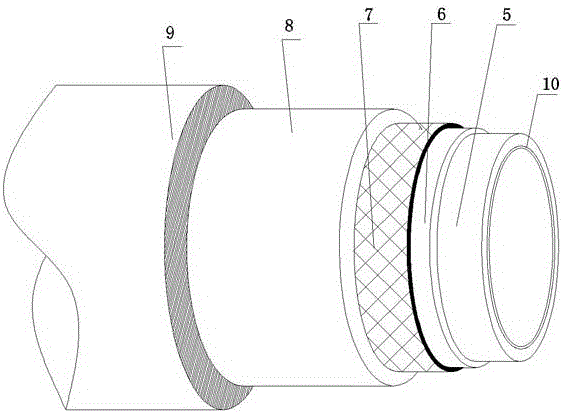

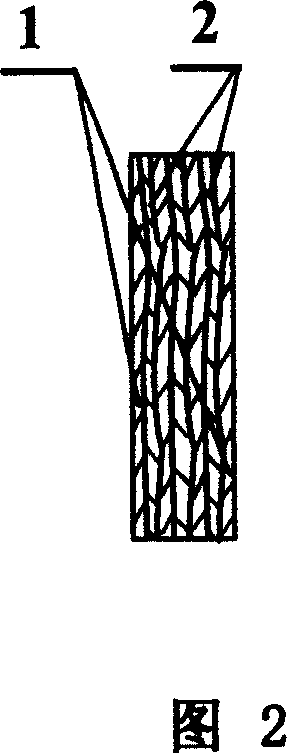

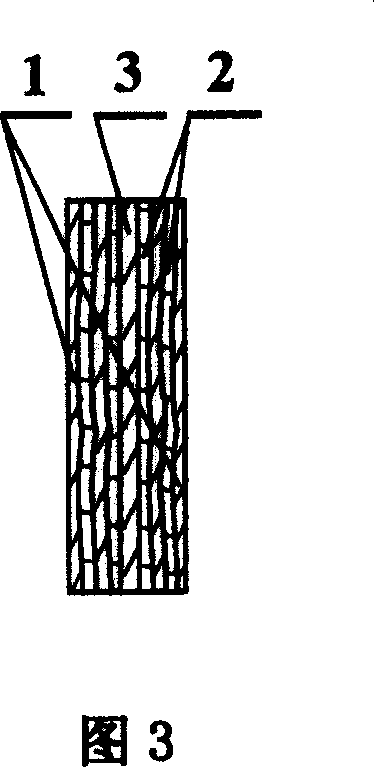

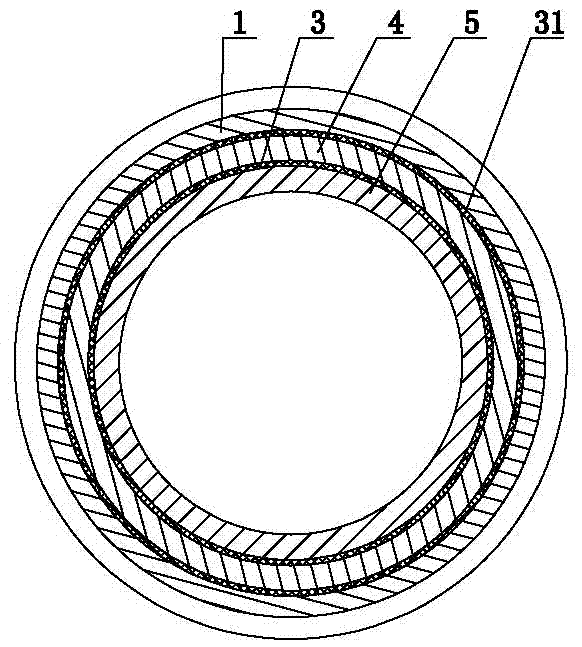

Corrosion-resistant hose assembly for swill collection vehicle

ActiveCN106499880BImprove corrosion resistanceExtended service lifeCorrosion preventionPipe protection against corrosion/incrustationEngineeringPipe layer

The invention discloses a corrosion resistant hosepipe assembly for a swill collection vehicle. The corrosion resistant hosepipe assembly comprises a hosepipe body, a metal silk screen layer, a rubber pipe layer, a spring shaping layer, a corrosion resistant membrane layer, a pipe connector body, an inner core pipe and a shrinking outer pipe. The hosepipe can have higher corrosion resistant performance and cannot be corroded by swill easily, the service life of the hosepipe assembly is effectively prolonged, the maintaining cost of the swill collection vehicle is reduced, the structure is reasonable, installation is convenient, and production, application and popularization are facilitated.

Owner:HAIYAN HAIGUAN PIPE FITTING MFG

Anaerobic reactor for vinasse wastewater treatment

ActiveCN114057293AImprove decomposition rateRapid responseWaste based fuelTreatment with anaerobic digestion processesMicroorganismWater soluble

The invention discloses an anaerobic reactor for vinasse wastewater treatment, and belongs to the field of anaerobic reactors, according to the scheme, wastewater is discharged into an anaerobic reactor body after being filtered through a water inlet pipe and a filter screen frame, anaerobic microorganisms in the anaerobic reactor body adsorb and decompose the wastewater, water-soluble balloons are dissolved in water, exposed reducing iron powder reacts with oxygen in water to generate ferroferric oxide, so that the iron element in the ferroferric oxide promotes the reaction of anaerobic microorganisms, shortens the anaerobic digestion reaction time, improves the decomposition rate of wastewater, increases the heat release, provides a good temperature environment for the growth and reaction of the anaerobic microorganisms, further improves the digestion reaction efficiency; and the wastewater flows to drive flowing blades to rotate, so that a rotating cylinder is driven to rotate through a first transmission wheel, a second transmission wheel and a transmission belt, and a memory stirring rod which is heated to bloom is driven to rotate and stir, so that the wastewater and anaerobic microorganisms are mixed and contacted more sufficiently, and the reaction effect is enhanced.

Owner:广东天泽环保科技有限公司

Wear-resistant and corrosion-resistant enamel glaze with good adhesion

The invention discloses wear-resistant corrosion-resistant enamel glaze with a good adhesive force. The wear-resistant corrosion-resistant enamel glaze comprises the following components by mass: 8-9 parts of micaceous, 1 part of sodium pyrophosphate, 6 parts of lithium oxide, 7 parts of boric anhydride, 4 parts of cobaltous oxide, 3 parts of barium oxide, 6 parts of aluminium oxide, 6-8 parts of feldspar, 4 parts of calcium oxide, 8 parts of sodium oxide, 8 parts of polyethylene wax powder, 7 parts of calcium fluoride, and 10-15 parts of quartz. The enamel glaze provided by the invention cannot fall off easily, and is wear-resistant and corrosion-resistant.

Owner:得宝搪瓷(中山)有限公司

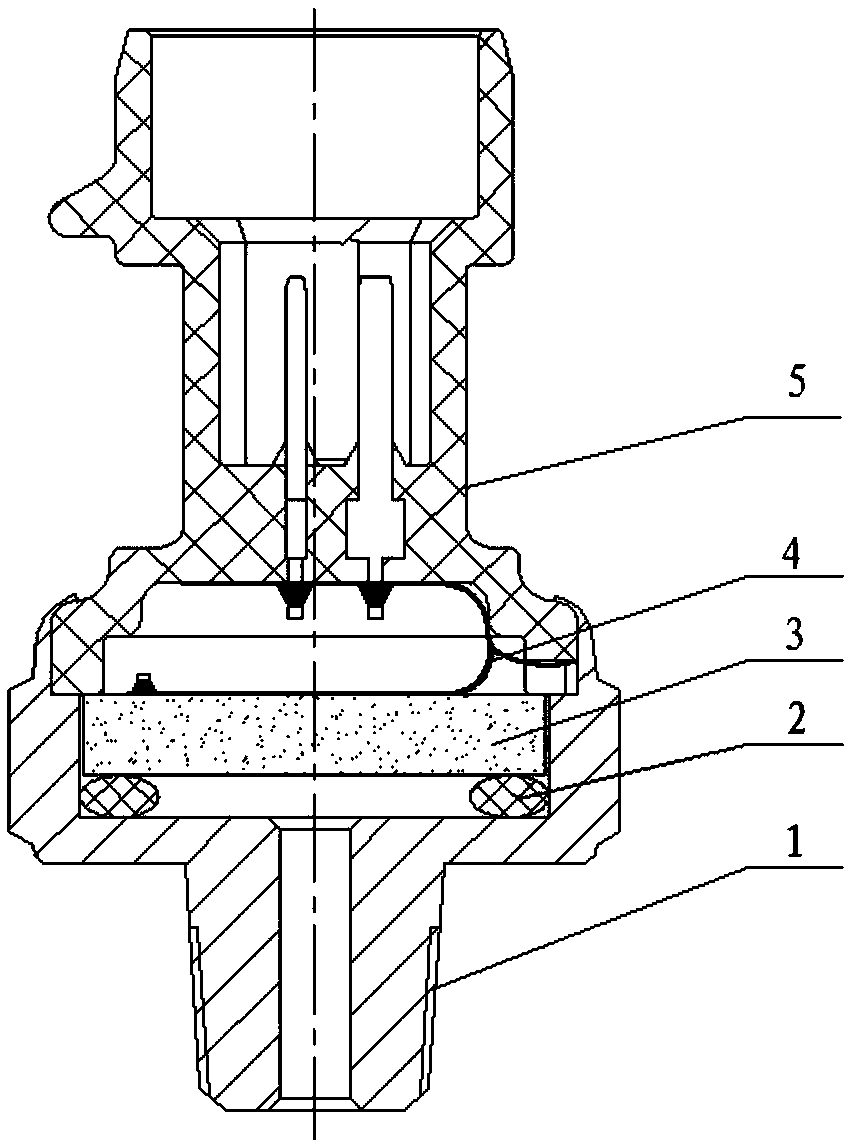

Novel pressure sensor

PendingCN109238520ANot easy to corrodeLittle influence of temperatureForce measurementFluid pressure measurement using capacitance variationCeramic capacitorWorking temperature

The invention provides a novel pressure sensor. The novel pressure sensor comprises a metal shell of the sensor, an end button, and a ceramic capacitive sensitive element assembly, wherein the lower end part of the end button is inserted into an opening in the top end of the shell, and the end button is mounted in a matched mode; the ceramic capacitive sensitive element assembly is mounted in themetal shell; an O-shaped sealing ring is arranged between the lower end of the ceramic capacitive sensitive element assembly and the shell; the ceramic capacitive sensitive element assembly and the end button are connected through a soft circuit board; the metal shell tightly presses the ceramic capacitive sensitive element, and the O-shaped sealing ring is extruded to form a sealing cavity. The novel pressure sensor is mainly used for detecting the external pressure, especially in an environment with certain corrosivity and wide working temperature range, and has the characteristics of compact structure, corrosion resistance, high and low temperature resistance and high reliability.

Owner:DONGFENG AUTOMOBILE ELECTRONICS

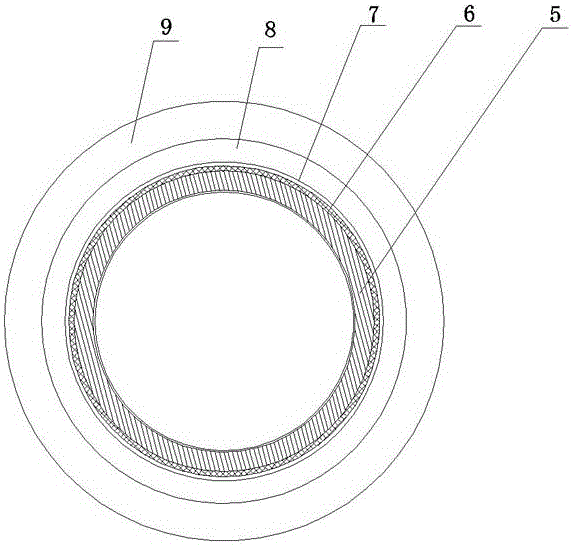

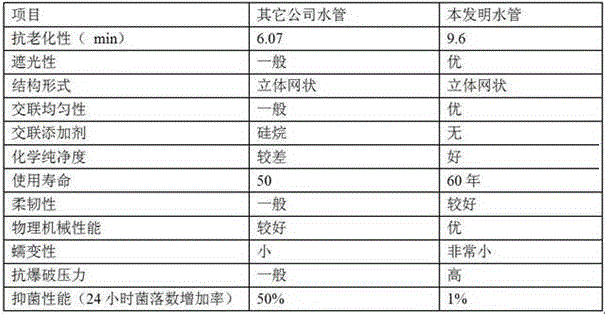

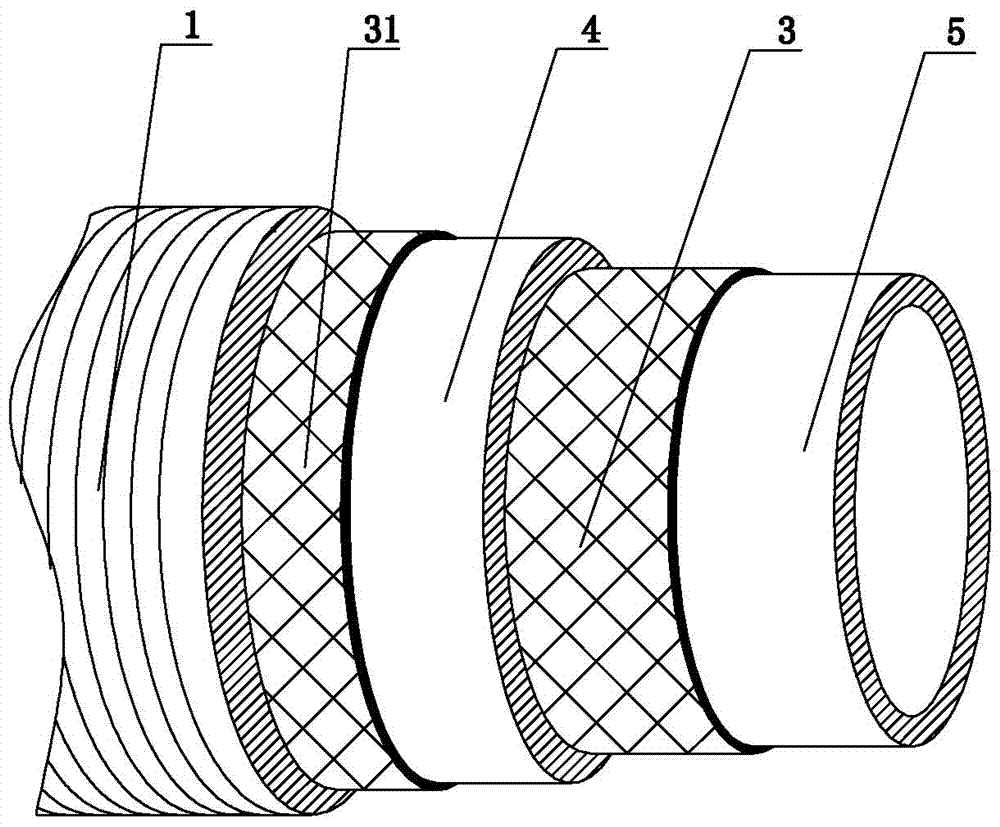

Ultrahigh molecular weight PP composite plastic water pipe

InactiveCN106641484AHigh bonding strengthHigh strengthGeneral water supply conservationFlexible pipesOrganic solventIrritation

The invention discloses an ultrahigh molecular weight PP composite plastic water pipe. The ultrahigh molecular weight PP composite plastic water pipe is characterized in that an innermost layer of the water pipe is an UHMWPP core pipe; the UHMWPP core pipe is wrapped by a first combination layer; the first combination layer is wrapped by a stainless steel wire net layer; the stainless steel wire net layer is wrapped by a PE middle combination layer; and the PE middle combination layer is wrapped by a HDPE weather resisting layer. The ultrahigh molecular weight PP composite plastic water pipe has such characteristics as high performances, high adaptability, high combination strength, bacteria resistance, no poison, no irritation, corrosion resistance and difficult rusting. A polyethylene weather resisting layer can resist erosion of such various corrosive mediums as acid, alkali, salt and organic solvent. The first combination layer and the PE middle combination layer both can be combined with different materials, and improve the pressure resisting strength of the pipe; the UHMWPP core pipe is high in strength, free of poison and environment-friendly; after the UHMWPP core pipe is combined with the stainless steel net layer by the first combination layer, the pressure resisting strength of the pipe can be further improved, and the pipe is not easy to break; under the condition of the same load, the pipe is higher than a steel pipe in strength by several times; and meanwhile, the pipe is excellent in impact resistance.

Owner:XIAOGAN JIARUI APPLICATION TECHNOLOGY DEVELOPMENT CO LTD

Manufacturing method of solar water heater

InactiveCN108489112AImprove durability and high temperature resistanceNot easy to produceSolar heating energySolar heat collector controllersWater storage tankWater quality

The invention discloses a manufacturing method of a solar water heater. The manufacturing method comprises the following steps of 1, manufacturing a water storage tank, wherein the water storage tankis made of a double-layer stainless steel plate, the middle of the water storage tank is filled with a heat preservation body with overall polyurethane foam, the interior of the double-layer stainlesssteel plate is coated with a black heat-absorption material, an exhaust port is formed in the upper portion of the water storage tank, and a sewage discharging port is formed in the lower portion ofthe water storage tank; and 2, manufacturing a support, wherein a thickened aluminum support is adopted, the slope between the support and the ground is 45 degrees, and support legs are formed by 9 cmultra-wide surfaces. Compared with other solar water heaters, the solar water heater has the advantages of being environment-friendly, good in heat preservation performance, mature in process and simple in installation technology, and that the use performance of the solar water heater is improved, the cleanness of water quality is guaranteed, and the service life is prolonged.

Owner:海宁市海创通日用品科技有限公司

Corrosion resistant hosepipe assembly for swill collection vehicle

ActiveCN106499880AImprove corrosion resistanceExtended service lifeCorrosion preventionFlexible pipesPipe layerMaterials science

The invention discloses a corrosion resistant hosepipe assembly for a swill collection vehicle. The corrosion resistant hosepipe assembly comprises a hosepipe body, a metal silk screen layer, a rubber pipe layer, a spring shaping layer, a corrosion resistant membrane layer, a pipe connector body, an inner core pipe and a shrinking outer pipe. The hosepipe can have higher corrosion resistant performance and cannot be corroded by swill easily, the service life of the hosepipe assembly is effectively prolonged, the maintaining cost of the swill collection vehicle is reduced, the structure is reasonable, installation is convenient, and production, application and popularization are facilitated.

Owner:HAIYAN HAIGUAN PIPE FITTING MFG

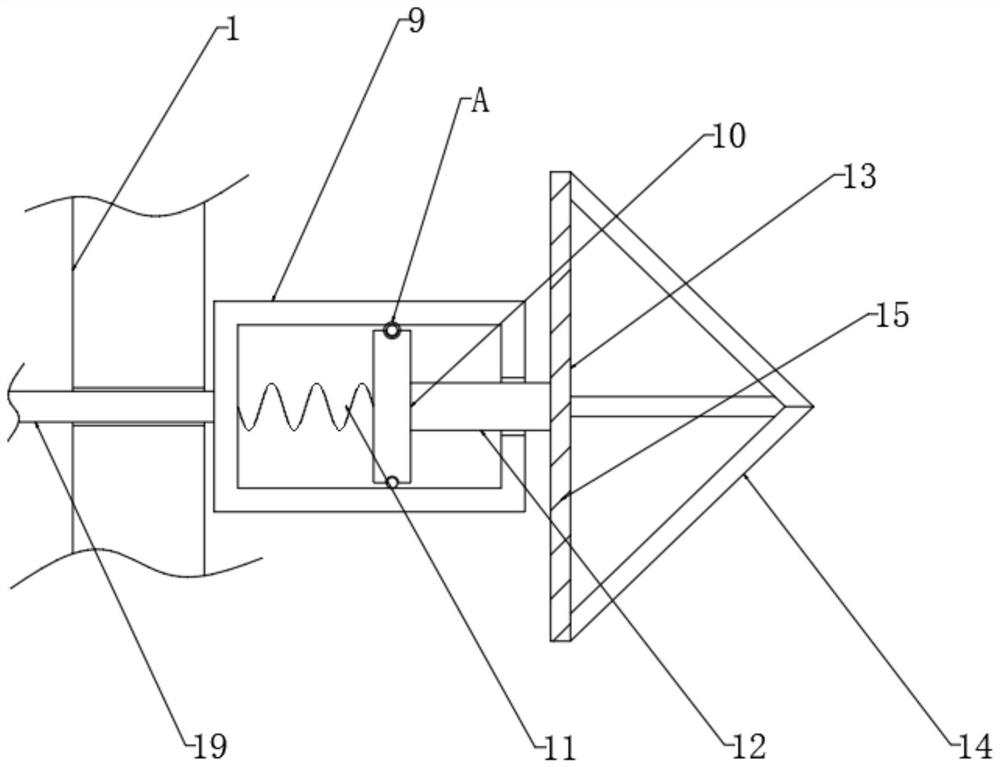

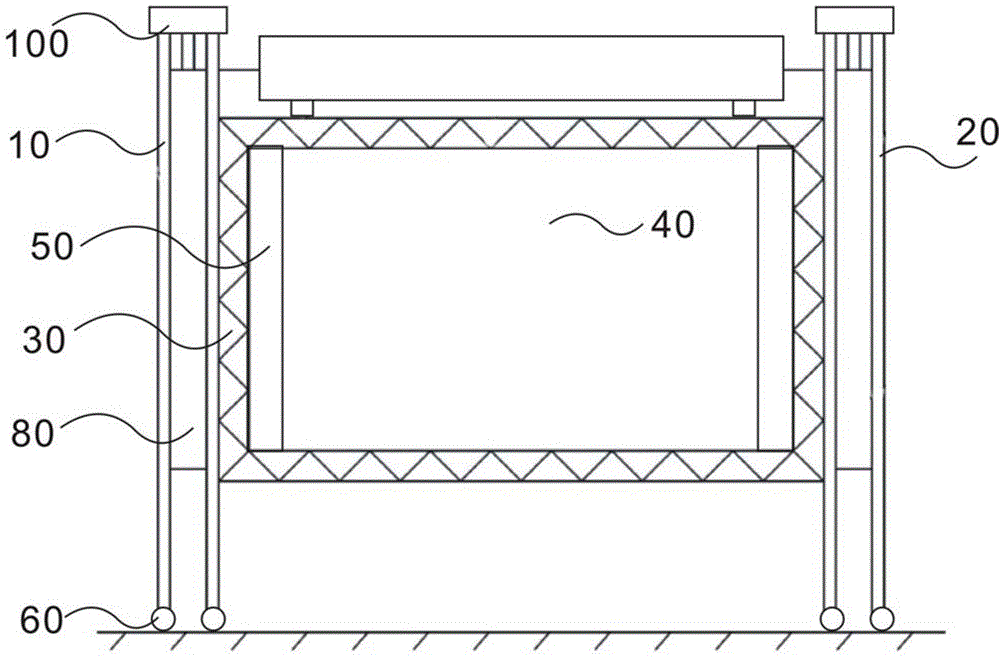

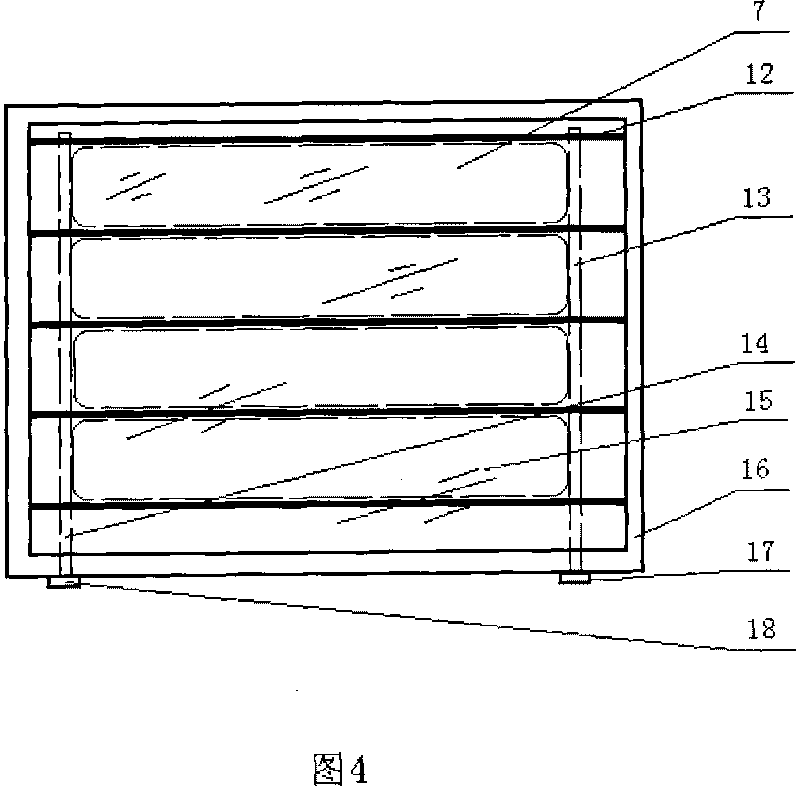

Corrosion-resistant movie screen stand

The invention relates to a corrosion-resistant movie screen frame, which comprises a left fixed frame, a right fixed frame, a screen frame, a screen screen and a curtain; the lower ends of the left fixed frame and the right fixed frame are provided with universal wheels, and the screen frame passes The rotating shaft is rotatably installed between the left fixed frame and the right fixed frame, the screen is installed on the screen frame, and the two sides of the screen are provided with arc-shaped strip-shaped anti-reflective plates, which can absorb part of the For light reflected by the screen, the outer walls of the left and right fixing frames are coated with a polymer fiber material layer, an arc-sprayed aluminum layer, and a galvanized layer in sequence. In the present invention, the polymer fiber material layer, the arc-sprayed aluminum layer and the galvanized layer are arranged to make it difficult to be corroded in the harsh external environment, so that the corrosion resistance of the entire movie screen frame is better, and its service life is prolonged.

Owner:SUZHOU HEIBAIHUAYING TELEVISION EQUIP CO LTD

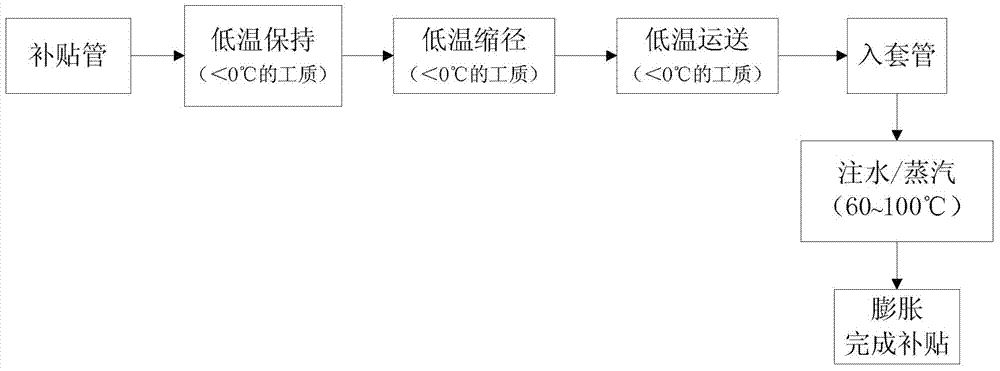

A copper-based memory alloy subsidized tube and its preparation method, subsidized method and use

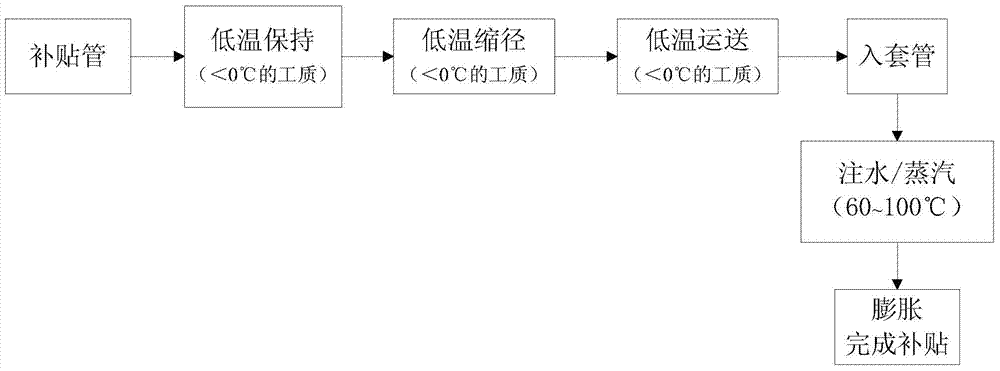

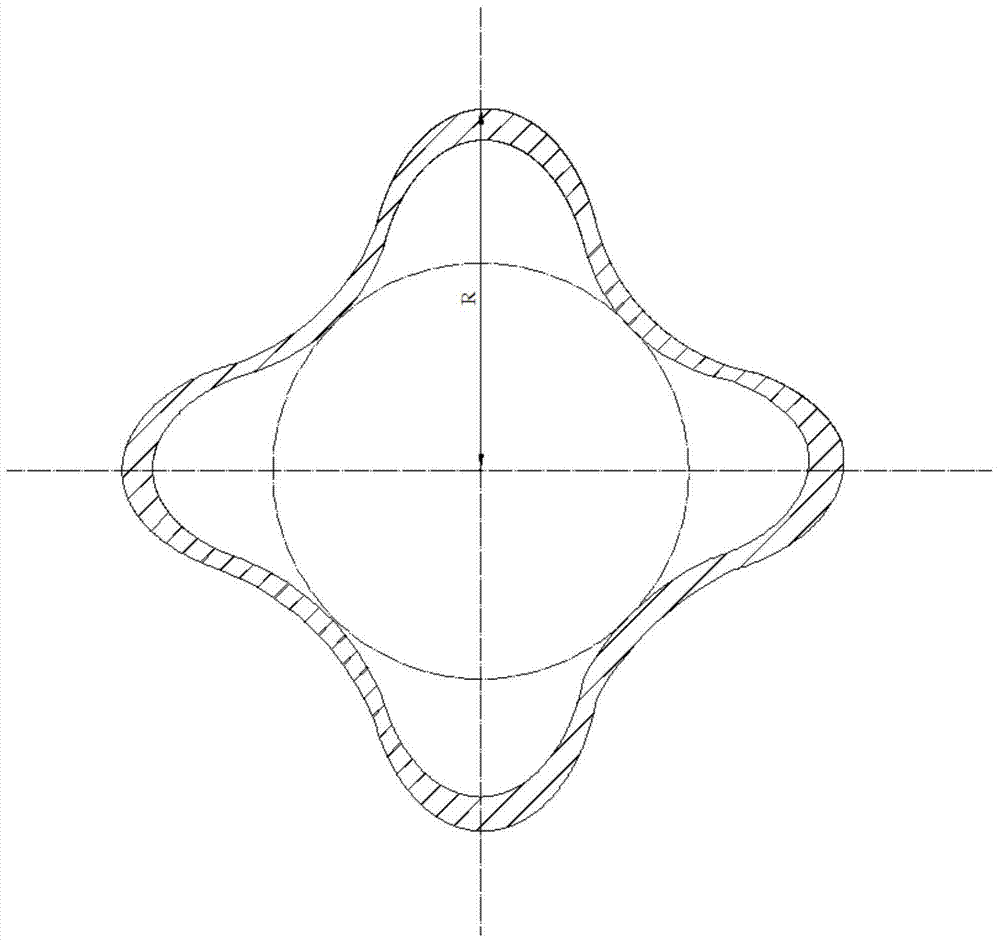

InactiveCN104831111BGood superelasticityIncreased maximum deformationBorehole/well accessoriesInterference fitWorking fluid

The invention provides a copper-based memory alloy subsidized pipe and its preparation method, subsidized method and application. The copper-based memory alloy includes the following elements in terms of mass percentage: Be: 0.2-1.6%, Al: 6-14%, Mn: 1-10%, Ga: 0-3% and 0 is not included, and impurities: 0-10%. 0.1%, the balance is Cu. The subsidized pipe is an alloy pipe with a wall thickness of 2.5-3.5mm, and its outer diameter is 3-4mm larger than the inner diameter of the bushing to be subsidized, and it can be pushed into a flower-shaped pipe in a working fluid of ≤0°C. The preparation method is as follows: taking raw materials according to the alloy composition and melting them, then cooling in a directional solidification cooling system to obtain ingots, and then performing thermomechanical treatment to obtain subsidized pipes. The subsidized pipe has a simple subsidizing process, and it can generate a strong interference fit with the casing to be subsidized, thereby generating a large sealing pressure and friction with the casing to prevent oil leakage and falling.

Owner:无锡源创机械科技有限公司

Multilayer composite patterned stainless steel and its mfg. method

InactiveCN1314534CNot easy to rustCorrosion resistance is not easyMetal rolling arrangementsMetal layered productsManufacturing technologyUltimate tensile strength

A patterned composite multi-layer stainless steel is composed of several stainless steel layers and the Ni layers and each Ni layer is positioned between two stainless steel layers. Its manufacture technology includes altenatively laminating the strainless steel sheets and Ni sheet, calendering at their fusing temp until needed thickness, patterning by grinding, carving or drilling, and rolling.

Owner:应卫忠

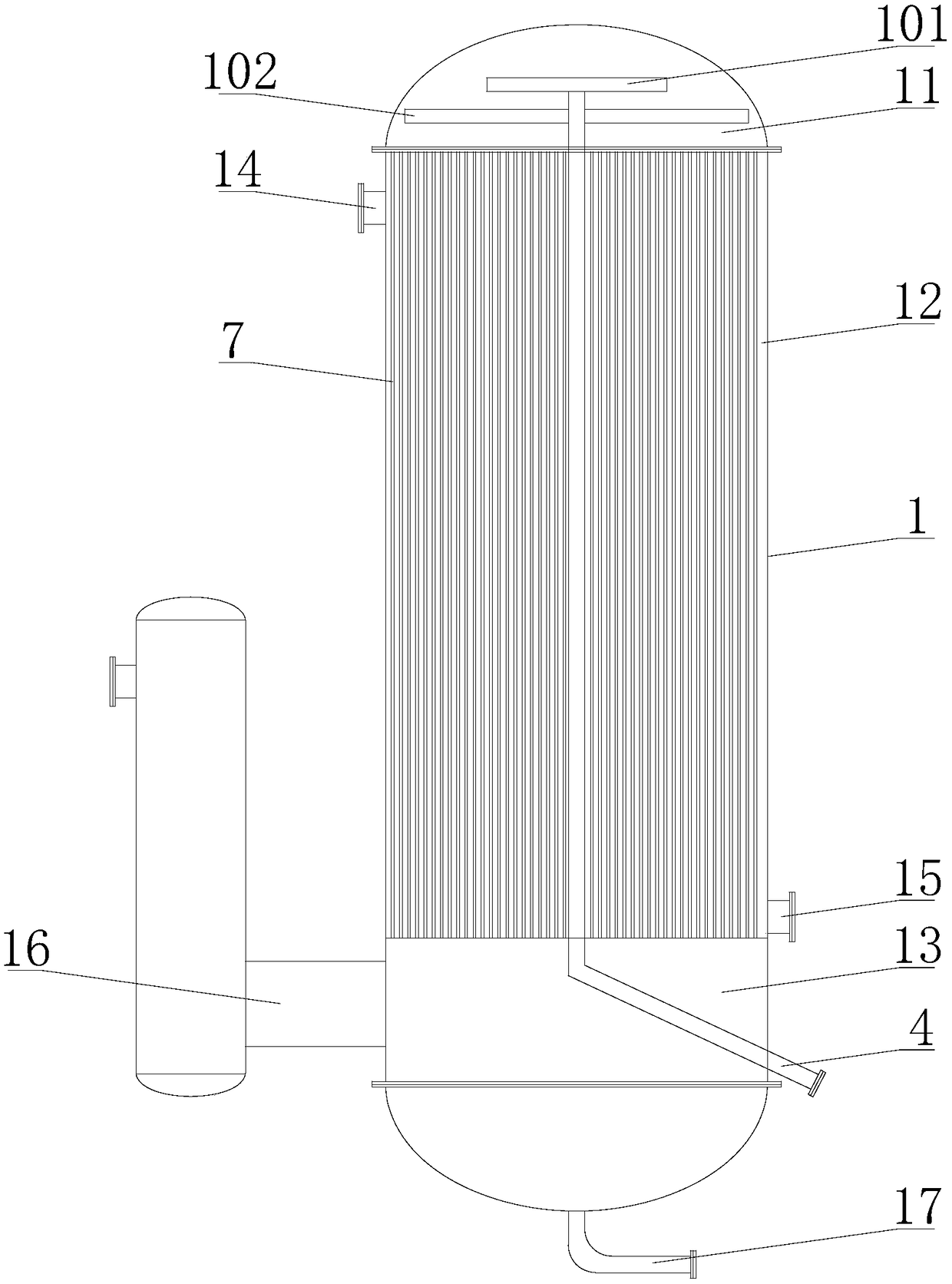

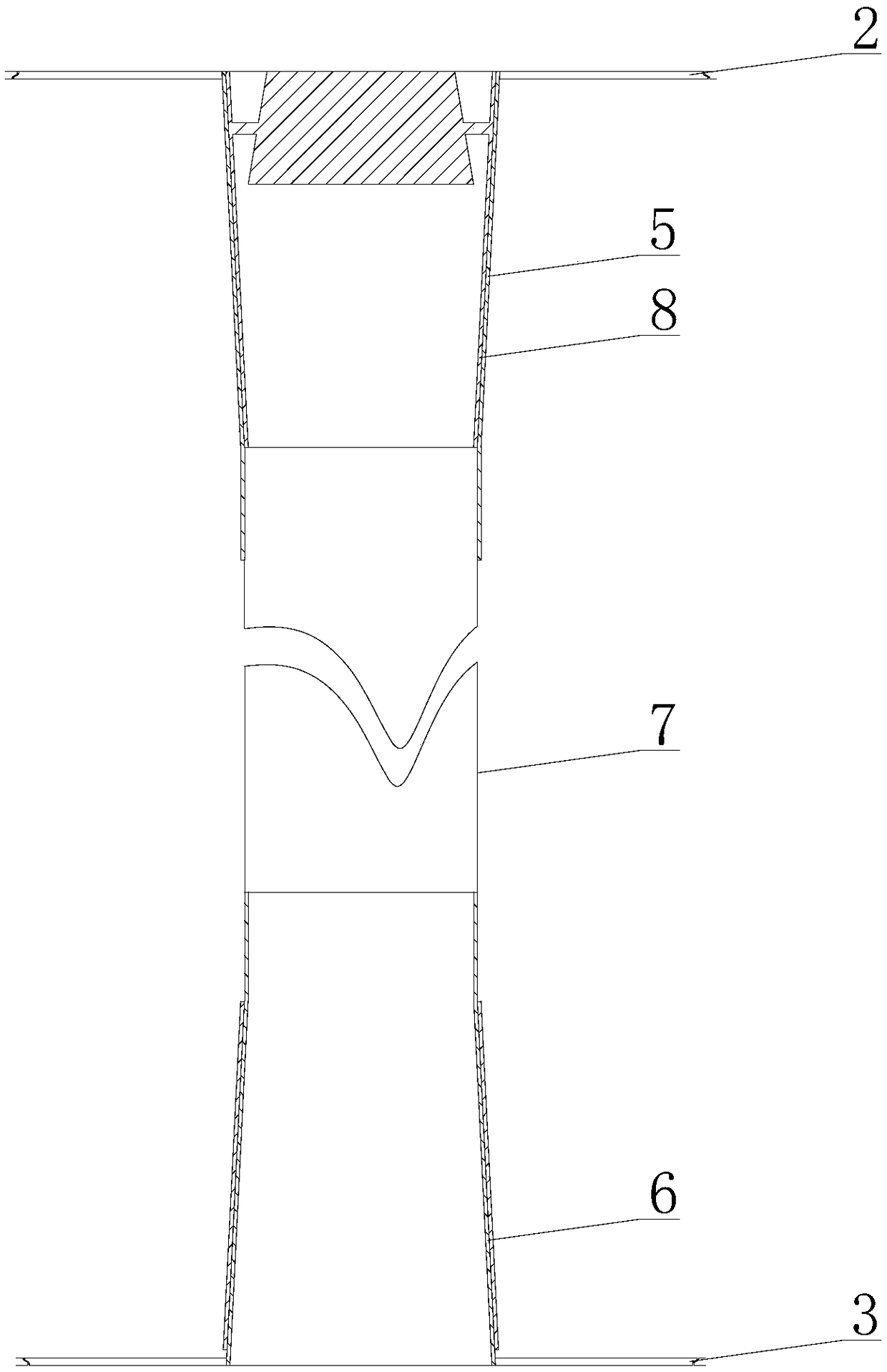

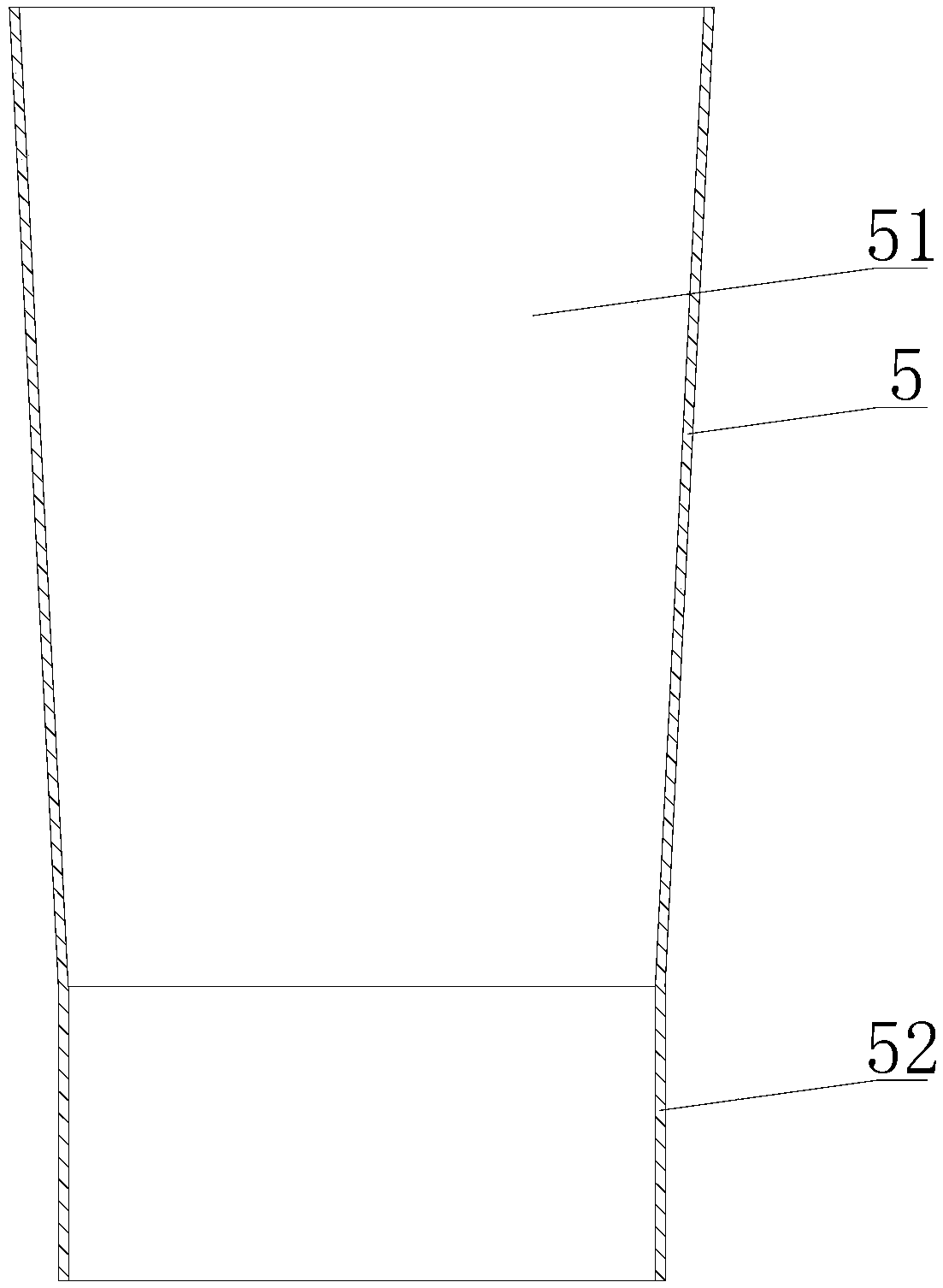

Membrane tube type falling film evaporator

PendingCN109157856AReliable connectionGood sealingEvaporator accessoriesCondensed waterAgricultural engineering

The invention provides a membrane tube type falling film evaporator and belongs to the technical field of evaporators. Problems that an existing membrane tube type falling film evaporator is easy to scale and easy to corrode because the existing membrane tube type falling film evaporator is made of metal are solved. The membrane tube type falling film evaporator comprises an evaporator body; an upper partition plate and a lower partition plate are arranged in the evaporator body; a cavity of the evaporator body is divided into a liquid inlet cavity, a heat exchanging cavity and a vapor-liquidseparating cavity by using the upper partition plate and the lower partition plate; a liquid inlet pipe communicated with the liquid inlet cavity is arranged on the evaporator body; a heated vapor inlet is formed in the upper part of the heat exchanging cavity; a condensed water outlet is formed in the lower part of the heat exchanging cavity; a secondary vapor outlet is formed in the upper part of the vapor-liquid separating cavity; a concentrated liquor outlet is formed in the lower part of the vapor-liquid separating cavity; a plurality of upper connecting heads are uniformly distributed onthe upper partition plate; a plurality of lower connecting heads are uniformly distributed on the lower partition plate; the upper connecting heads and the lower connecting heads are communicated with each other through vertical membrane tubes; and a film-distributor is arranged at the upper ends of the vertical membrane tubes. The membrane tube type falling film evaporator provided by the invention has the advantage that the heat exchanging efficiency is effectively enhanced by using the vertical membrane tubes to replace metal tubes while the manufacturing cost is reduced.

Owner:上海三耕储节能环保科技有限公司

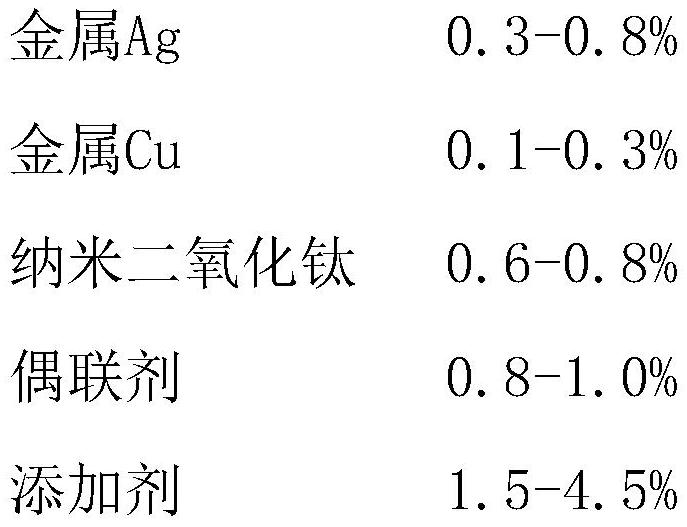

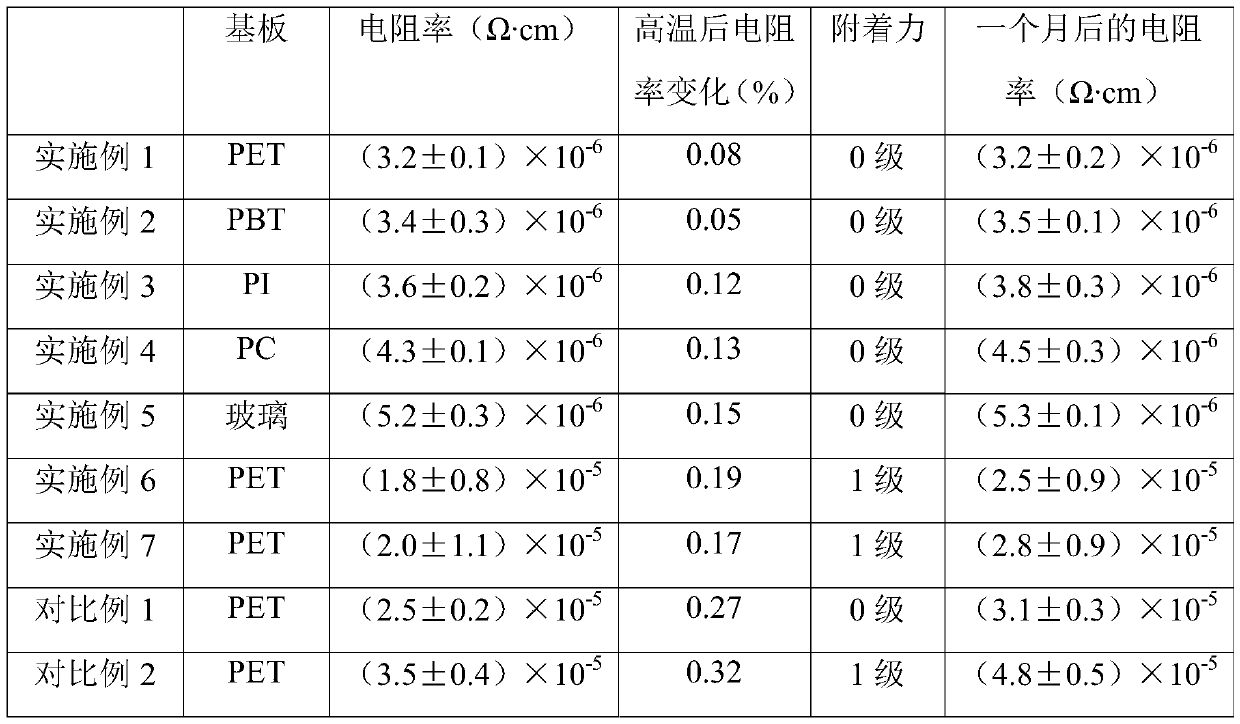

Antistatic coating taking rare-earth-modified barium zirconate titanate nano-powder as conductive filler, and preparation method thereof

InactiveCN101781511BNot easily oxidizedCorrosion resistance is not easyInorganic pigment treatmentEpoxy resin coatingsPolymer scienceConductive polymer

The invention provides an antistatic coating taking rare-earth-modified barium zirconate titanate nano-powder as conductive filler, and a preparation method thereof, which belongs to the field of antistatic coatings. The invention solves the problems that the prior metal powder serving as conductive filler of antistatic coatings is high in cost, big in surface resistivity change after high-temperature aging, and the like. The antistatic coating is prepared from polymer matrix, rare-earth-modified barium zirconate titanate nano-powder, diluent, curing agent and coupling agent. The preparation method comprises the following steps: weighing polymer matrix, diluent, curing agent and coupling agent respectively, mixing the materials well and then placing the mixture for 1 hour; adding rare-earth-modified barium zirconate titanate nano-powder and then performing ultrasonic dispersion for 5 minutes; performing normal-temperature curing to obtain the antistatic coating. The antistatic coatinghas the characteristics of low cost, strong anti-aging property, simple process method and no environmental pollution. After one hour of aging at 150 DEG C, the surface resistivity change of the antistatic coating is 5.3 to 7.8 percent.

Owner:HARBIN INST OF TECH

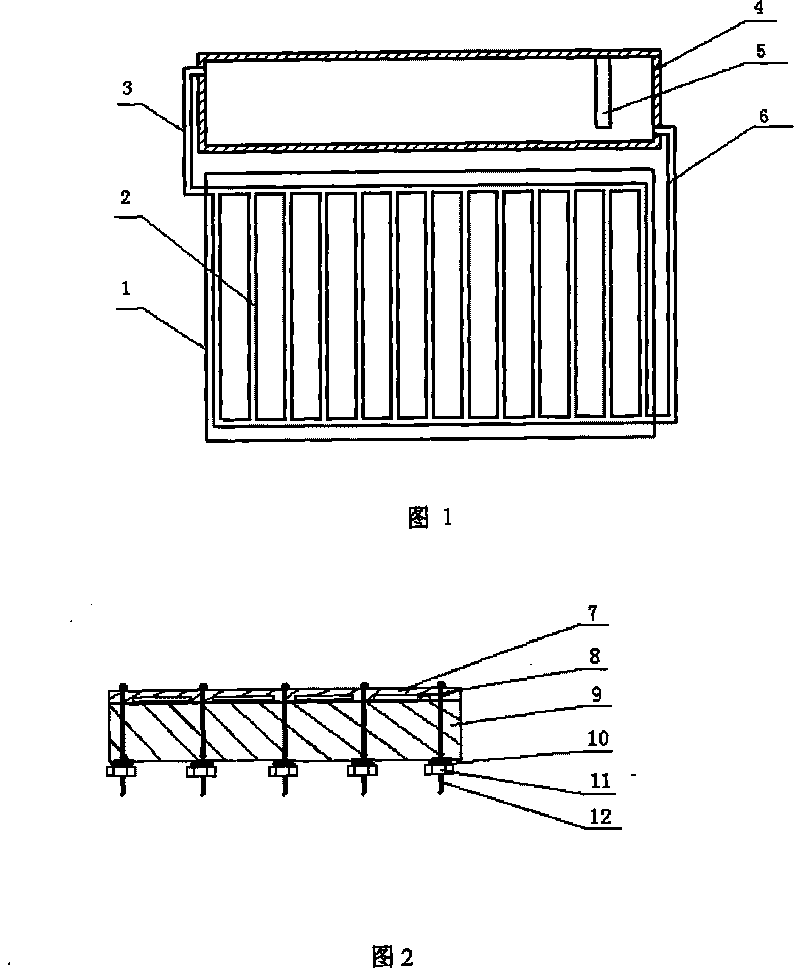

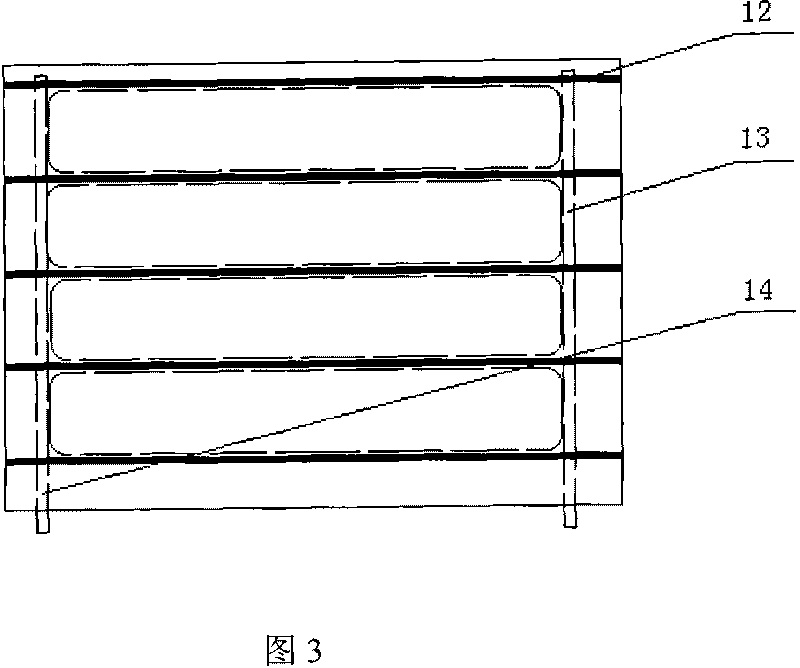

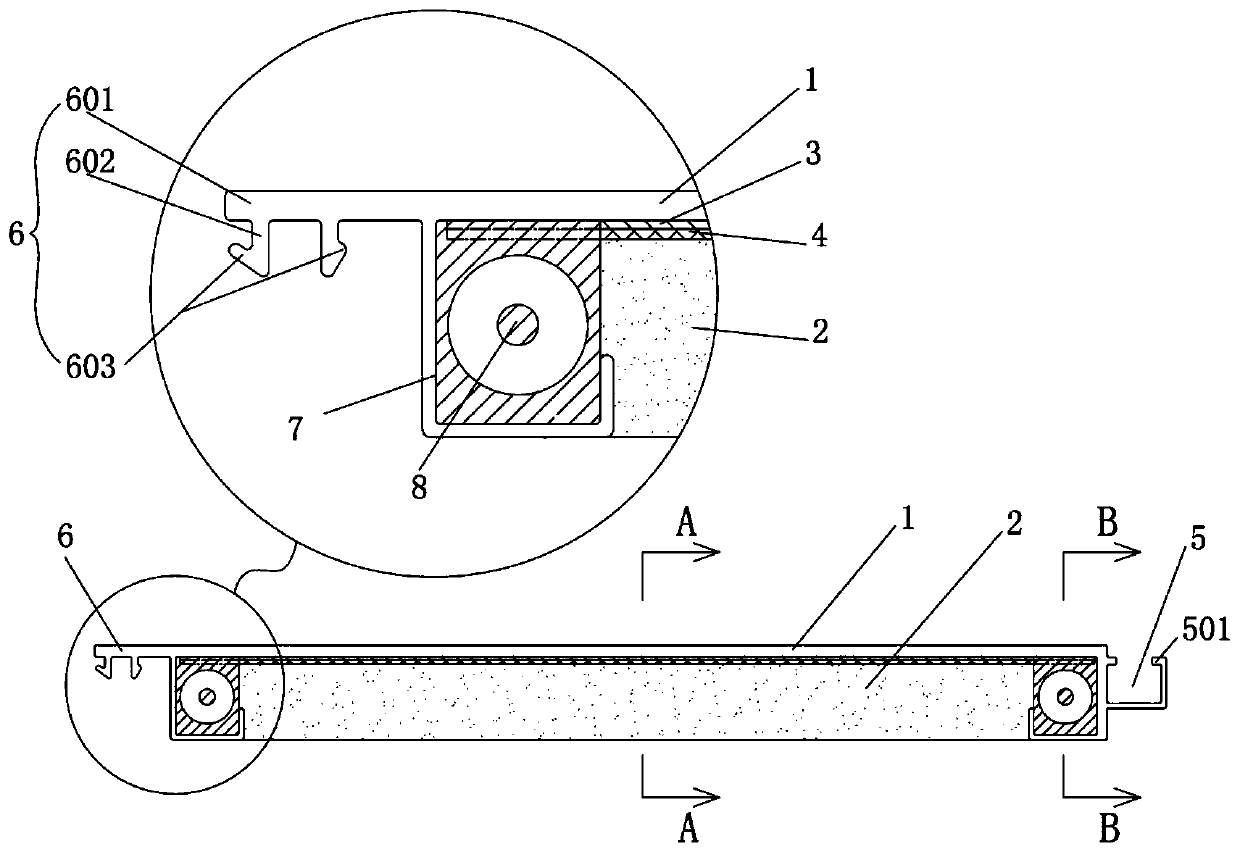

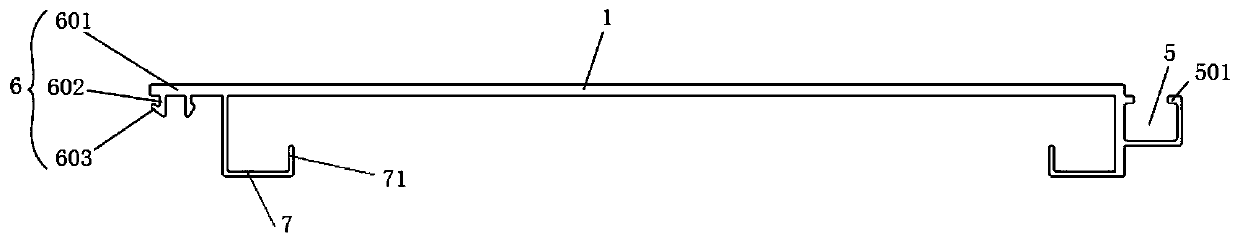

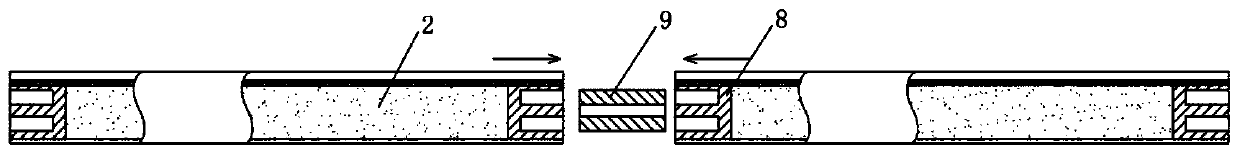

Heat collection and heat exchange component, solar heat collection plate and solar heat collector

InactiveCN101487633BImprove heat collection and heat exchange efficiencySimple processSolar heating energySolar heat devicesEngineeringAntifreeze

The invention provides a heat collecting and transferring component, comprising a pair of plate-shaped components which are arranged in the opposite directions and a fixing and sealing structure which is used for fixing and sealing the plate-shaped components, wherein, a concave part is formed on at least one of the plate-shaped components; at least one of the plate-shaped components is made by heat conduction material; when the plate-shaped components are bonded together by the fixing and sealing structure, the concave part forms a closed space which is provided with at least an inlet and atleast an outlet. The invention further provides a solar heat-collecting panel and a solar heat collector. The solar heat-collecting panel is provided with the heat collecting and transferring component; and the solar heat collector is provided with the solar heat-collecting panel. The heat collecting and transferring component has the advantages of antifreeze property, high heat collecting and transferring efficiency, little possibility of scale formation, corrosion resistance, simple process and low cost. The solar heat-collecting panel and the solar heat collector not only improve heat collecting efficiency, but also reduce production cost.

Owner:华群

Pulverized coal boiler pipeline material resisting high temperature and corrosion

The invention discloses a high-temperature-resistant and corrosion-resistant pulverized coal boiler pipe material, wherein the high-temperature-resistant and corrosion-resistant boiler pipe material consists of the following components in parts by weight: 3-8 parts of curing agent; 12-15 parts of turpentine 1-3 parts of toluene; 2-7 parts of barium sulfate; 8-15 parts of sulfur; 2-6 parts of magnesium oxide; 8-10 parts of universal carbon black; and 25-42 parts of calcium carbonate. The invention provides a high-temperature-resistant and corrosion-resistant pulverized coal boiler pipe material. The boiler pipe using the material works under the action of high temperature, stress and corrosive medium, and is not only resistant to high temperature, but also not easily oxidized and corroded.

Owner:WUXI XINENG BOILER

Plate, heating plate with same, and preparation process of heating plate

PendingCN109945274AOmit process stepsSave man hoursLighting and heating apparatusSpace heating and ventilation detailsElectricityEngineering

Owner:刘文晓

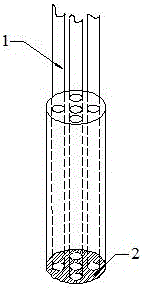

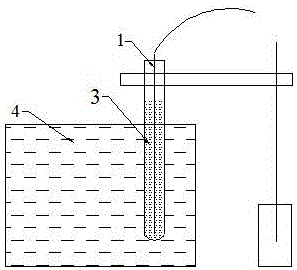

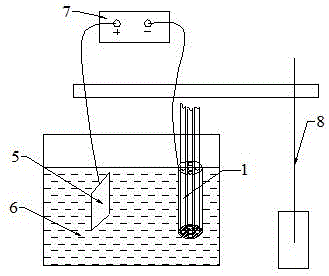

A method for manufacturing high temperature resistant bundled optical fibers

ActiveCN104152899BHigh sensitivityWide range of measurement applicationsSuperimposed coating processFine lineChemical plating

The invention provides a manufacturing method for high-temperature resistant bundling optical fibers. The manufacturing method for high-temperature resistant bundling optical fibers comprises the following steps: a plurality of common optical fibers are taken; surface sensitization treatment and surface activation treatment are conducted on the common optical fibers respectively; then, a chemical plating is conducted; the thickness of a clad layer is 4-8 micron; the length that the clad layer protects is 150-250 mm; chemically plated optical fibers are tied into a bundle by adopting thin strings; the end parts of the chemically plated optical fibers are in parallel and level; the bundle of chemically plated optical fibers is placed into an electroplating liquid for electroplating, so that all the optical fibers are enabled to be tightly combined and optical fiber bundles are formed; the diameter of the entire bundling optical fibers is 0.5-1 mm; the length that the electroplating clad layer protects is 100-200 mm. According to the manufacturing method for the high-temperature resistant bundling optical fibers, through conducting surface metallization on the common optical fibers, the plurality of optical fibers are made into the bundling optical fibers; the bundling optical fibers have the advantages of low probability of damages, high-temperature resistance, high transmission information capacity and the like; the multiple bundling optical fibers are wrapped with a sensing probe, so as to form a multi-channel transmitting bundling optical fibers; the information transmission capacity is large; the manufacturing method for the high-temperature resistant bundling optical fibers can be used for fields of simultaneous distinction and measurement of multiple physical quantities, or a detection probe of the bundling optical fibers and the like.

Owner:NANCHANG UNIV

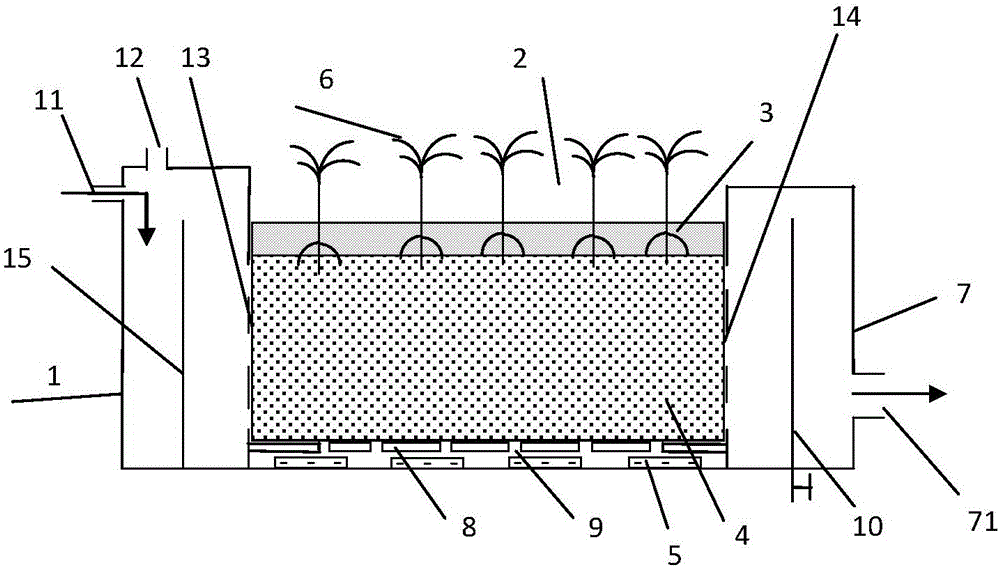

Enhanced palm micro-ecological filter bed system

InactiveCN106145366AImprove water retentionNot easy to be flexibleBiological treatment apparatusSustainable biological treatmentPalm fiberSurvival rate

The invention relates to an enhanced palm micro-ecological filter bed system, comprising a water incoming area, a filter bed and a water outgoing area; a first overflow wall is provided between the water incoming area and the filter bed, a second overflow wall is provided between the water outgoing area and the filter bed, and the filter overflow wall and the second overflow wall are provided with through holes respectively; the water incoming area is provided with a water inlet, and the water outgoing area is provided with a water outlet; the filter bed is composed of a planting layer, a palm filter layer, a through-hole wall and an aerating pipe from top to bottom, the through-hole wall is provided with a plurality of air holes, purifying plants are planted in the planting layer, the aerating pipe and the palm filter layer are isolated by the through-hole wall, and iron ore filling material is arranged in the palm filter layer; a lifting partition is disposed in the water outgoing area. The system with the palm fiber can effectively increase survival rate of plants in the planting layer and ensure long-term availability of the filter bed; with a certain amount of iron ore added to the filter bed, treating capacity of the whole ecological filter bed can be effectively improved.

Owner:ZHEJIANG ZHENGJIE ENVIRONMENTAL SCI & TECH CO LTD

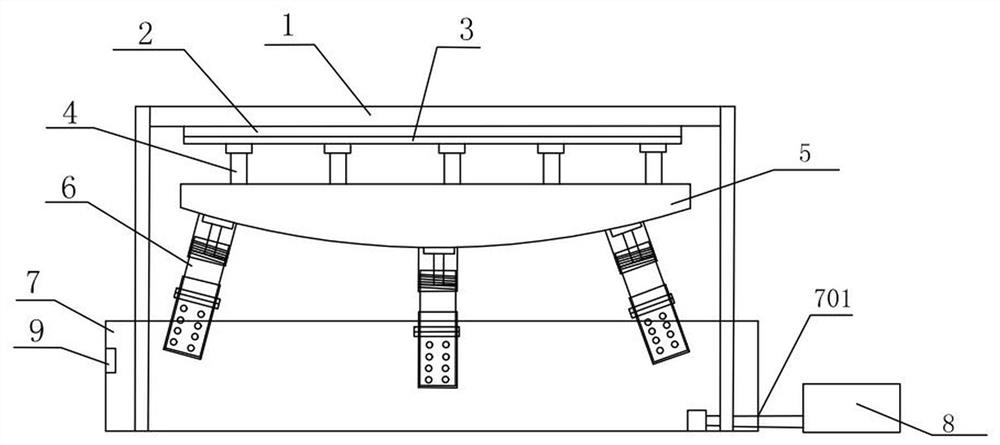

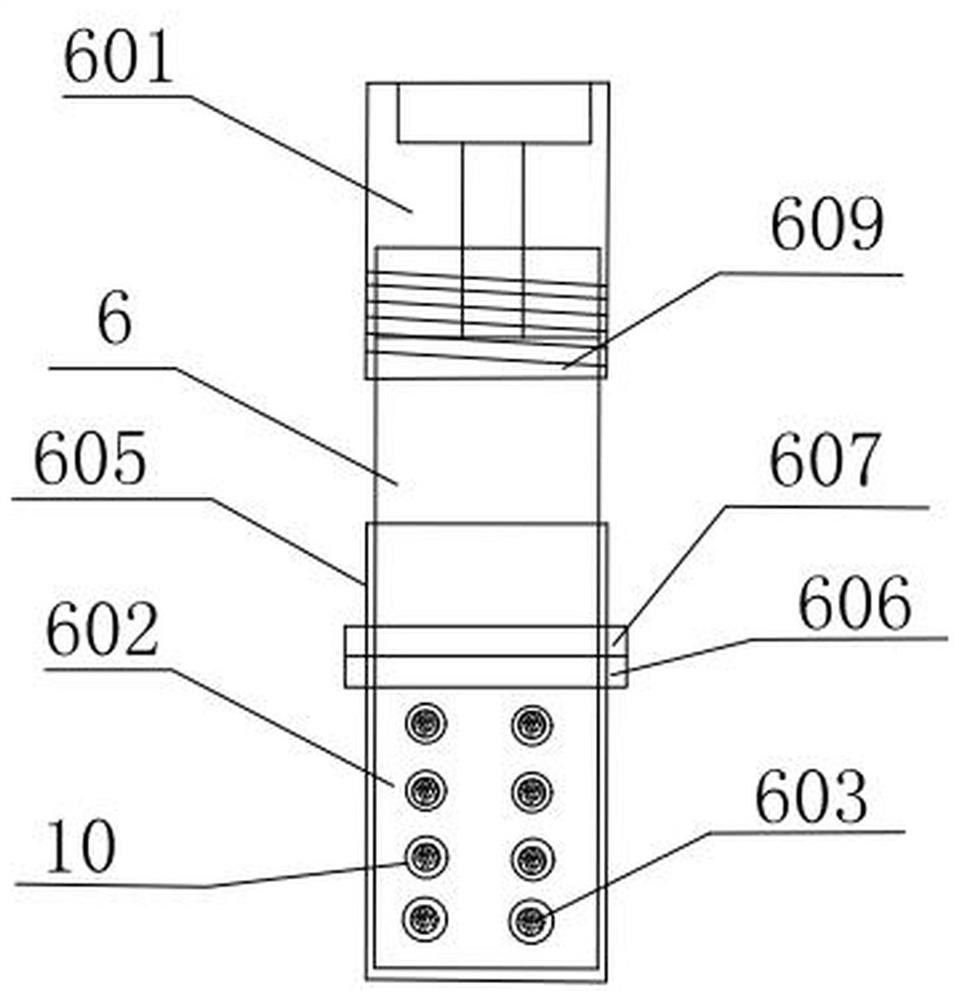

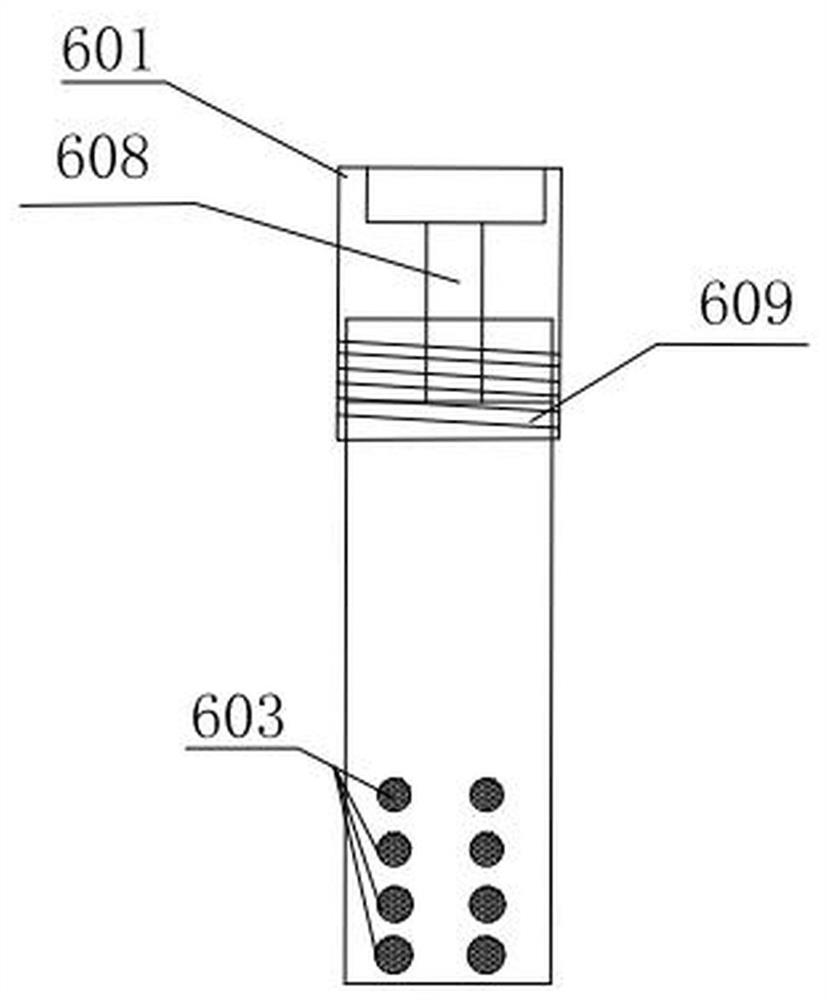

Heat-resistant plastic preparation system

The invention relates to the technical field of plastic processing, in particular to a heat-resistant plastic preparation system which comprises a stirring device, the stirring device is connected with a double-screw-rod extruder, a discharging port of the double-screw-rod extruder is connected with a film blowing machine, and the stirring device comprises a top plate, and the lower plate face of the top plate is connected with a rotating motor. The output end of the rotating motor is connected with a rotating plate, the lower plate face of the rotating plate is connected with a plurality of first hydraulic cylinders, telescopic rods of the first hydraulic cylinders are connected with a fixing seat, the lower surface of the fixing seat protrudes, and a plurality of mixing devices are arranged on the edge of the fixing seat. The mixing device comprises a first sleeve, the upper end of the first sleeve is fixedly connected with the fixing seat, the lower part of the inner wall of the first sleeve is provided with an internal thread, and the inner thread of the first sleeve is provided with a second sleeve. According to the preparation system disclosed by the invention, the loss of fine particles such as cryptocrystalline graphite in the reaction process is prevented, and the solid-liquid separation of the fine particles after the reaction is facilitated.

Owner:深圳市得利鑫科技有限公司

New high pressure hdpe water pipe

ActiveCN103062520BImprove bindingHigh strengthGeneral water supply conservationRigid pipesOrganic solventShock resistance

Disclosed is a novel high pressure resistant high-density polyethylene (HDPE) water pipe. An HDPE core tube is arranged on an innermost layer of the water pipe, a first stainless steel wire mesh layer is wrapped on the outside of the HDPE core tube, an HDPE intermediate combined layer is wrapped on the outside of the first stainless steel wire mesh layer, a second stainless steel wire mesh layer is wrapped on the outer wall of the HDPE intermediate combined layer, and an HDPE weather-proof layer is wrapped on the outside of the second stainless steel wire mesh layer. The novel high pressure resistant HDPE water pipe has the advantages of being high in performances, applicability and bonding strength, non-toxic, non-irritant, corrosion resistant, not prone to be rusted and the like. The polyethylene weather-proof layer can be resistant to corrosion of various corrosive media such as acids, alkali, salt and organic solvents and is not like materials such as steel tubes which can produce electrocorrosion and foster corrosion damage, and the service life of the polyethylene weather-proof layer can reach to 50 years. By means of the first and second stainless steel wire mesh layers, the compressive strength of a high strength HDPE corrugated pipe can be improved, and the high strength HDPE corrugated pipe is not prone to crack and simultaneously has a good shock resistance.

Owner:河北鑫鹏通信设备有限公司

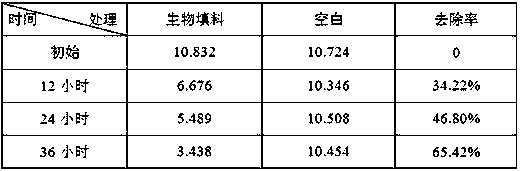

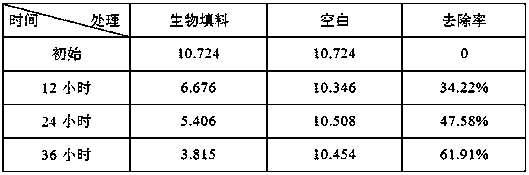

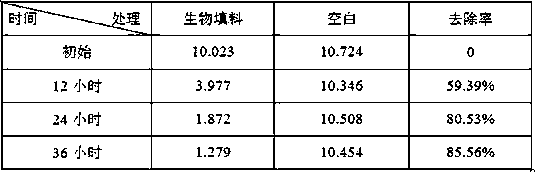

A kind of biological filler for strengthening the adsorption of phosphorus and its preparation method and use

ActiveCN105036302BSimple preparation processReduce manufacturing costWater contaminantsSustainable biological treatmentConstructed wetlandFlat glass

The invention discloses biological stuffing capable of absorbing phosphorus intensively and a preparation method and application thereof. The stuffing is prepared with kieselguhr and glass, and the preparation method comprises the steps of firstly, mixing the kieselguhr with the glass, conducting ball milling, obtaining a powder batch mixture, then conducting foaming and annealing treatment, and obtaining the novel biological stuffing, wherein the kieselguhr which is used is common silicious rock, and the glass can be waste sheet glass. The biological stuffing has the main effect and advantages that the preparation process is simple, the obtained biological stuffing has good absorbing effect on the phosphorus, by means of porous structures which are formed simultaneously, biomembrane loading is faciliated, environmental protection problems are solved, and meanwhile high economic benefits are acquired. In addition, the biological stuffing can achieve good effect in constructed wetland and a biological filter tank, and the biological stuffing has the advantages of being low in application cost and long in application cycle.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com