New high pressure hdpe water pipe

A high pressure, water pipe technology, applied in the field of pipelines, can solve the problems of low compressive strength, easy corrosion and rust of pipes, poor impact resistance, etc., and achieves the effects of good strength, high applicability, and good impact resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

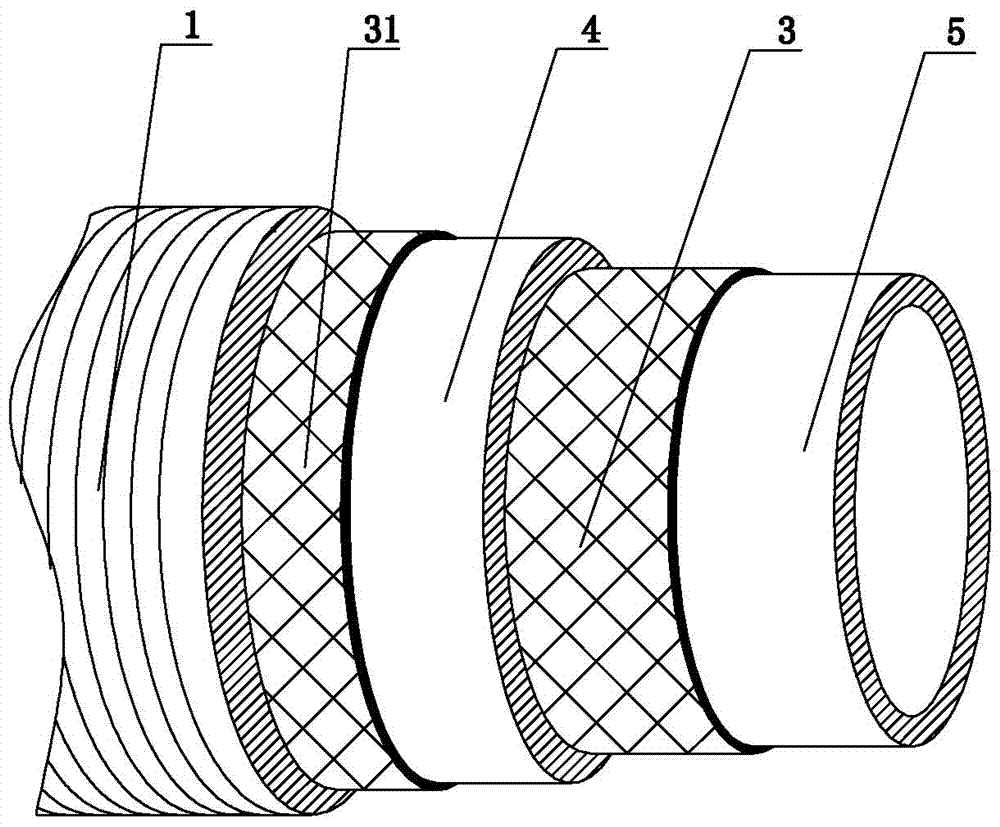

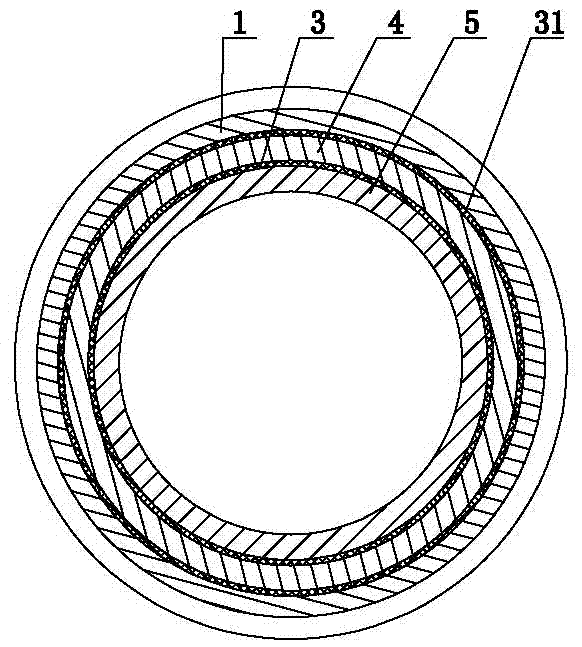

[0016] Embodiment 1: 50 parts by weight of HDPE resin, composite filler (by weight percentage: silicon dioxide 58%, hematite 7%, calcium sulfate whisker 5%, wollastonite 5%, sodalite 10 %, calcium carbonate 15%) and 5 parts are mixed and put into the hopper of the first extruder; 50 parts of HDPE resin (high-density polyethylene), 0.2 part of sorbitol, and 5 parts of thermoplastic polyurethane elastomer are put into the second extruder according to the weight ratio. Taiwan extruder hopper; 80 parts of HDPE resin, 5 parts of calcium carbonate, 1 part of calcium stearate, 2 parts of nano-scale titanium dioxide, tetrakis[β-(3,5-di-tert-butyl-4-hydroxy 0.3 parts of phenyl) propionic acid] pentaerythritol ester, 0.3 parts of phenyl o-hydroxybenzoate, and 0.2 parts of polyethylene wax are mixed and put into the hopper of the third extruder; during production, the first extruder extrudes 5 HDPE core tubes After the extruded HDPE core tube 5 is water-cooled and sized, the stainless st...

Embodiment 2

[0017] Embodiment 2: by weight 50 parts of HDPE resin, composite filler (by weight percentage: silicon dioxide 50%, hematite 7%, calcium sulfate whisker 10%, wollastonite 10%, sodalite 5% %, calcium carbonate 15%) and 5 parts are mixed and put into the hopper of the first extruder; 50 parts of HDPE resin (high density polyethylene), 0.7 part of sorbitol, and 3 parts of thermoplastic polyurethane elastomer are put into the second extruder according to the weight ratio In the hopper of the extruder; by weight 83 parts of HDPE resin, 8 parts of calcium carbonate, 3 parts of calcium stearate, 2 parts of nano-sized titanium dioxide, tetrakis [β-(3,5-di-tert-butyl-4-hydroxybenzene base) propionic acid] 0.4 part of pentaerythritol ester, 0.4 part of phenyl o-hydroxybenzoate, and 0.2 part of polyethylene wax are mixed and put into the hopper of the third extruder; the production method is the same as above.

Embodiment 3

[0018] Embodiment 3: 50 parts by weight of HDPE resin, 5 parts of composite filler (by weight percentage: silicon dioxide 60%, hematite 4%, calcium sulfate whisker 10%, wollastonite 10%, soda Stone 5%, calcium carbonate 8%) 5 parts are mixed and put into the hopper of the first extruder; 50 parts of HDPE resin (high density polyethylene), 1.1 parts of sorbitol, and 8 parts of thermoplastic polyurethane elastomer are put into the first extruder according to the weight ratio In the hopper of two extruders; 85 parts of HDPE resin, 10 parts of calcium carbonate, 5 parts of calcium stearate, 3 parts of nano-scale titanium dioxide, tetrakis[β-(3,5-di-tert-butyl-4 -Hydroxyphenyl) propionic acid] 0.5 part of pentaerythritol ester, 0.5 part of phenyl o-hydroxybenzoate, 0.3 part of polyethylene wax in the hopper of the third extruder; the production method is the same as above.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com