Isolated axial flow pump blade

An axial flow pump, independent technology, applied in the field of independent axial flow pump blades, can solve the problems of impeller material not fully applicable, too many corrosive substances, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

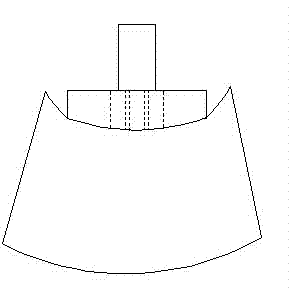

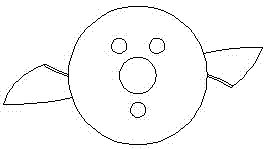

[0019] See the attached figure, the independent axial flow pump blade, the main body of the blade is a disc-shaped connecting part, one side of the disc is a spiral blade structure, and the other side is a cylindrical shaft structure, the blade body is made of injection molding, and the material is thermosetting resin nano Composite material, the outer surface of the blade main body is covered with ultra-high molecular weight polyethylene coating; the side connecting the disc connecting part and the spiral blade is arc-shaped; the connecting part of the disc is connected concentrically with the cylinder shaft; There is an adhesive layer between the coatings through frosting treatment; the ultra-high molecular weight polyethylene coating is: ultra-high molecular weight polyethylene UHMWPE LS4140, ultra-high molecular weight polyethylene UHMWPE L3000, Japan Mitsui Chemicals ultra-high molecular weight polyethylene UHMWPE L4000, ultra-high molecular weight polyethylene High molecu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com