A method for manufacturing high temperature resistant bundled optical fibers

A manufacturing method and high-temperature-resistant technology, applied in the direction of superimposed layer plating, metal material coating process, coating, etc., can solve problems such as inability to apply high-temperature detection, and achieve wide application of optical fiber measurement, large transmission information capacity, and transmission fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

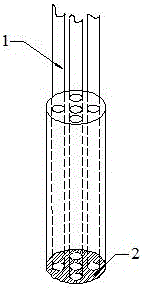

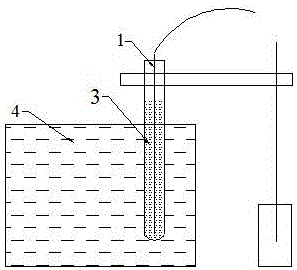

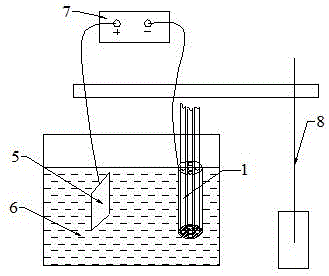

[0026] Embodiment 1: Get 3 optical fibers, according to the formula of sensitization solution (SnCl 2 2H 2 O is 10g / L; HCl is 40ml / L), activation solution formula (PdCl 2 0.5g / L; HCl is 5ml / L) to prepare sensitizing solution and activation solution respectively, and activate them after sensitization at a temperature of 25°C for 15min and 20min respectively, and then according to the formula of electroless copper plating solution (CuSO 4 ·5H 2 O is 10g / L; NaKC 4 h 4 o 6 ·5H 2 O is 40g / L; NaCO 3 2g / L; NiCl 2 ·H 2 O is 1g / L; HCHO is 20ml / L; NaOH is 10g / L) prepare electroless copper plating solution, carry out electroless copper plating when temperature is 25 ℃, time is 4h, as figure 2 As shown, the thickness of the coating is 4 μm, and the length of the electroless coating is 150 mm. Then according to the electroplating solution formula (CuSO 4 250g / L; glucose 40g / L; H 2 SO 4 70g / L) to prepare an electroplating copper solution, tightly bundle the chemically plated o...

Embodiment 2

[0027] Embodiment 2: Get 5 optical fibers, press the sensitizing solution formula (SnCl 2 2H 2 O is 10g / L; HCl is 40ml / L), activation solution formula (PdCl 2 0.5g / L; HCl is 5ml / L) to prepare sensitizing solution and activation solution respectively, and activate them after sensitization at a temperature of 25°C for 15min and 20min respectively, and then according to the formula of electroless copper plating solution (CuSO 4 ·5H 2 O is 10g / L; NaKC 4 h 4 o 6 ·5H 2 O is 40g / L; NaCO 3 2g / L; NiCl 2 ·H 2 O is 1g / L; HCHO is 20ml / L; NaOH is 10g / L) prepare electroless copper plating solution, carry out electroless copper plating when temperature is 25 ℃, the time is 5h, as figure 2 As shown, the thickness of the coating is 6 μm, and the length of the electroless coating is 200 mm. Then according to the electroplating solution formula (CuSO 4 250g / L; glucose 40g / L; H 2 SO 4 70g / L) to prepare an electroplating copper solution, tightly bundle the chemically plated optical f...

Embodiment 3

[0028] Embodiment 3: get 8 optical fibers, press the formula of sensitization solution (SnCl 2 2H 2O is 10g / L; HCl is 40ml / L), activation solution formula (PdCl 2 0.5g / L; HCl is 5ml / L) to prepare sensitizing solution and activation solution respectively, and activate them after sensitization at a temperature of 25°C for 15min and 20min respectively, and then according to the formula of electroless copper plating solution (CuSO 4 ·5H 2 O is 10g / L; NaKC 4 h 4 o 6 ·5H 2 O is 40g / L; NaCO 3 2g / L; NiCl 2 ·H 2 O is 1g / L; HCHO is 20ml / L; NaOH is 10g / L) prepare electroless copper plating solution, carry out electroless copper plating when temperature is 25 ℃, the time is 6h, as figure 2 As shown, the thickness of the coating is 8 μm, and the length of the electroless coating is 250 mm. Then according to the electroplating solution formula (CuSO 4 250g / L; glucose 40g / L; H 2 SO 4 70g / L) to prepare an electroplating copper solution, tightly bundle the chemically plated optic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com