A copper-based memory alloy subsidized tube and its preparation method, subsidized method and use

A technology of memory alloy and subsidized pipe, which is applied in the direction of earthwork drilling and production, wellbore/well parts, etc., can solve the problems of easy corrosion, high cost, poor thermoelastic phase transition performance, etc., and achieve good thermoelastic phase transition performance and low cost The effect of low cost and simple subsidy process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

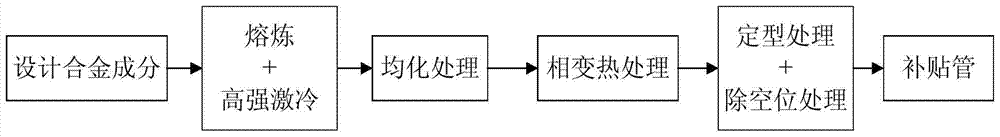

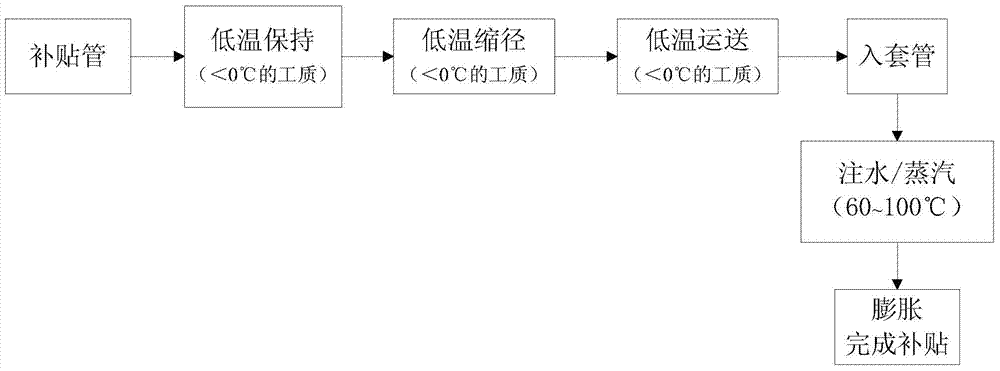

[0080] Embodiment 1: the preparation of subsidy tube

[0081] According to the Sichuan area with high average temperature all year round and the conditions of high oilfield temperature in summer, it is required that the temperature Ms at which martensite transformation begins is -10°C, and the temperature at which martensite reverse transformation begins As is 40-50°C. The temperature Af at which the bulk inversion is terminated is 60-100°C.

[0082] (1) Design alloy composition: Al: 11%, Be: 0.38%, Mn: 3%, Ga: 1%, and the balance is Cu. The calculated Ms(°C) is -2.67°C, the measured As is 40-50°C, and the Af is 70-95°C, meeting the requirements.

[0083] (2) Add metal Cu, metal Al, metal Mn, metal Be and metal Ga into a vacuum melting furnace for vacuum melting according to the designed alloy composition. The vacuum degree is 10 Pa, and the melting temperature is 1180 ° C. In the high-strength directional solidification cooling equipment, it is poured into an oxygen-free sh...

Embodiment 2

[0085] Embodiment 2: the preparation of subsidy pipe

[0086] (1) The composition of the alloy is designed, and the mass percentage of the contained metal elements is obtained as follows: Al: 10%, Be: 0.3%, Mn: 2%, Ga: 0.1%, and the balance is Cu.

[0087] (2) Except that the degree of vacuum is 1 Pa, the melting temperature is 1100° C., and other steps are the same as step (2) in Example 1. The obtained ingot has a diameter of 150 mm and a length of about 100 mm.

[0088] (3) Thermomechanical treatment: In addition to the homogenization treatment temperature is 850 ° C, the homogenization time is 12 hours; the initial rolling temperature of hot forging is 840 ° C, the termination temperature is 620 ° C; the hot rolling temperature is 750 ° C; reverse extrusion at 830 ° C Press into a thin-walled tube with a diameter of 200mm, a wall thickness of 4mm, and a length of 3m; the setting temperature is 800°C, the setting time is 1mm, and the effective thickness is kept for 360s; ex...

Embodiment 3

[0089] Embodiment 3: the preparation of subsidy tube

[0090] (1) Design the alloy composition to obtain the mass percentage of the contained metal elements: Al: 12%, Be: 0.6%, Mn: 4%, Ga: 1%, and the balance is Cu.

[0091] (2) Except that the degree of vacuum is 8Pa, the melting temperature is 1220° C., other steps are the same as step (2) in Example 8, and the obtained ingot has a diameter of 100 mm and a length of about 50 mm.

[0092] (3) Thermomechanical treatment: In addition to the homogenization treatment temperature is 860 ° C, the homogenization time is 24 hours; the initial rolling temperature of hot forging is 820 ° C, the termination temperature is 600 ° C; the hot rolling temperature is 840 ° C; reverse extrusion at 820 ° C Press into a thin-walled tube with a diameter of 80mm, a wall thickness of 3.5mm, and a length of 1m; the setting temperature is 820°C, the setting time is 1mm, and the effective thickness is kept for 60s; except that the vacancy treatment te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com