Copper-clad steel tinned wire and preparation process thereof

A preparation process and technology of copper-clad steel, applied in cable/conductor manufacturing, rod/rod/wire/strip conductor, conductor and other directions, can solve problems such as affecting normal transmission, unfavorable processing and use, affecting wire flexibility, etc. High strength, high practicability, surface tension reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

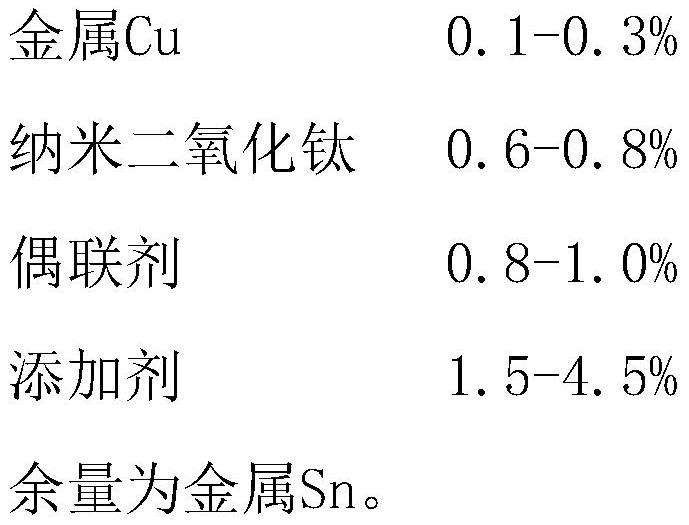

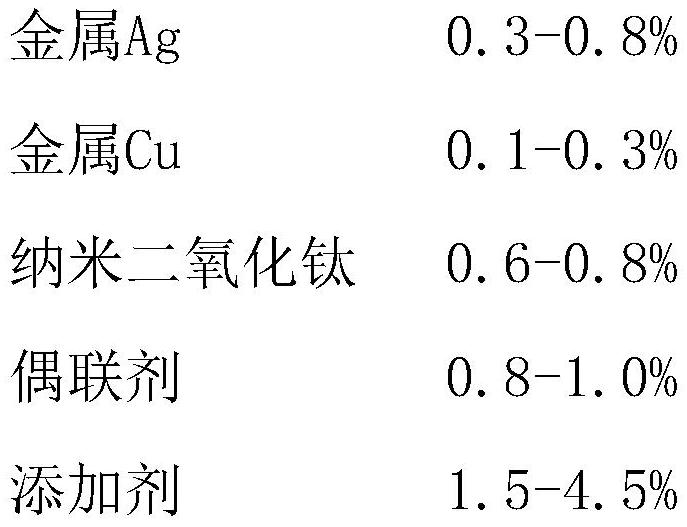

Embodiment 1

[0037] A tinned copper-clad steel wire rod comprises a core layer, a copper layer and a tinned layer from the inside to the outside in sequence, and the thickness of the tinned layer is 1 μm.

[0038] The core layer comprises 95% low carbon steel with a carbon content of <0.25% and 5% copper.

[0039] A preparation process for copper-clad steel tinned wire rod as described above, comprising the steps of:

[0040] A, steel wire drawing: the steel wire is drawn to a steel wire with a diameter of 0.5mm through the wire drawing equipment to obtain the core layer;

[0041] B, electroplating copper layer: the core layer obtained in step A is surface-cleaned to remove stains, then electroplated copper on the surface of the core layer, and dried to obtain a copper-clad steel wire rod coated with a copper layer;

[0042] C, wire drawing and annealing treatment: the copper-clad steel wire rod that step B is made is drawn to the copper-clad steel fine wire that diameter is 0.05mm by dra...

Embodiment 2

[0057] A tinned copper-clad steel wire rod comprises a core layer, a copper layer and a tinned layer from inside to outside sequentially, and the thickness of the tinned layer is 1.5 μm.

[0058] The core layer comprises 96% mild steel with a carbon content of <0.25% and 4% copper.

[0059] A preparation process for copper-clad steel tinned wire rod as described above, comprising the steps of:

[0060] A, steel wire drawing: the steel wire is drawn to a steel wire with a diameter of 0.8mm through the wire drawing equipment to obtain the core layer;

[0061] B, electroplating copper layer: the core layer obtained in step A is surface-cleaned to remove stains, then electroplated copper on the surface of the core layer, and dried to obtain a copper-clad steel wire rod coated with a copper layer;

[0062] C, wire drawing and annealing treatment: the copper-clad steel wire rod that step B is made is drawn to the copper-clad steel thin wire that diameter is 0.06mm by drawing equipm...

Embodiment 3

[0077] A tinned copper-clad steel wire rod comprises a core layer, a copper layer and a tinned layer from inside to outside sequentially, and the thickness of the tinned layer is 2 μm.

[0078] The core layer comprises 97% mild steel with a carbon content of <0.25% and 3% copper.

[0079] A preparation process for copper-clad steel tinned wire rod as described above, comprising the steps of:

[0080] A, steel wire drawing: the steel wire is drawn to a steel wire with a diameter of 1.0 mm through a wire drawing equipment to obtain a core layer;

[0081] B, electroplating copper layer: the core layer obtained in step A is surface-cleaned to remove stains, then electroplated copper on the surface of the core layer, and dried to obtain a copper-clad steel wire rod coated with a copper layer;

[0082] C, wire drawing and annealing treatment: the copper-clad steel wire rod that step B is made is drawn to the copper-clad steel thin wire that diameter is 0.06mm by drawing equipment, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com