Carbon oil and preparation method thereof

A carbon oil and graphene technology, which is applied in the preparation of carbon oil and in the field of carbon oil, can solve the problems of large differences in chemical active properties, poor high temperature resistance, affecting the service life of equipment, etc., and achieves low copper content, The effect of improved conductivity, easy storage and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

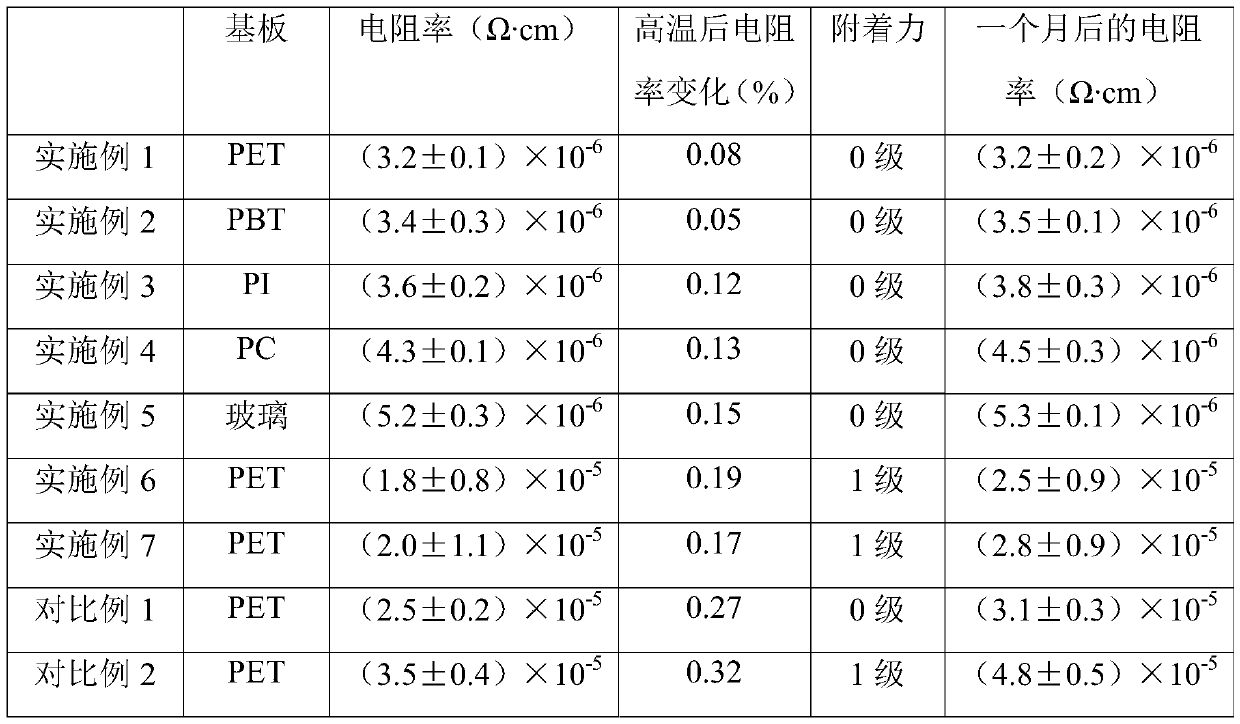

Examples

preparation example Construction

[0032] Second aspect, the present invention provides a kind of preparation method of carbon oil, comprises the following steps:

[0033] (1) Graphene, acetylene black and solvent are ultrasonically dispersed to obtain a dispersion;

[0034] (2) mixing the above dispersion with poly(3,4-ethylenedioxythiophene)-polystyrenesulfonic acid, hydroxypropyl cellulose, and copper nanoparticles, and grinding to obtain the carbon oil;

[0035] Among them, in parts by mass, poly(3,4-ethylenedioxythiophene)-polystyrenesulfonic acid takes 5-10 parts, acetylene black takes 4-10 parts, graphene takes 4-10 parts, hydroxypropyl fiber Take 0.1-1 parts for plain, 1-2 parts for copper nanoparticles, and 16-32 parts for solvent.

[0036] Specifically, in step (1), the graphene and acetylene black in the dispersion liquid obtained by ultrasonic dispersion need to be completely dispersed in the solvent as much as possible. The ultrasonic power is generally 1250-1500W. The ultrasonic time can be dete...

Embodiment 1

[0044] (1) 70g of three-layer graphene, 70g of acetylene black and 240g of water were mixed and placed in an ultrasonic disperser with an ultrasonic power of 1400W for 50min to obtain a dispersion.

[0045] (2) Mix 70g of poly(3,4-ethylenedioxythiophene)-polystyrenesulfonic acid, 3g of hydroxypropyl cellulose, and 13g of copper nanoparticles with the above dispersion, and manually grind for 60min to obtain solid particles Carbon oil with a diameter of 4 μm.

Embodiment 2

[0047](1) After mixing 60 g of two-layer graphene, 50 g of acetylene black and 200 g of water, place it in an ultrasonic disperser with an ultrasonic power of 1300 W and disperse for 30 min to obtain a dispersion.

[0048] (2) Mix 60g of poly(3,4-ethylenedioxythiophene)-polystyrenesulfonic acid, 1g of hydroxypropyl cellulose, and 10g of copper nanoparticles with the above dispersion, and manually grind for 45min to obtain solid particles Carbon oil with a diameter of 5 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com