A copper-based memory alloy subsidized tube and its preparation method, subsidized method and use

A memory alloy and subsidy tube technology, which is applied in earth-moving drilling, wellbore/well components, etc., can solve the problems of easy corrosion, high cost, poor thermo-elastic phase change performance, etc., and achieve good thermo-elastic phase change performance and cost. The effect of low and simple subsidy process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

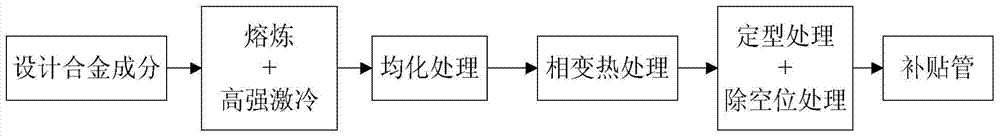

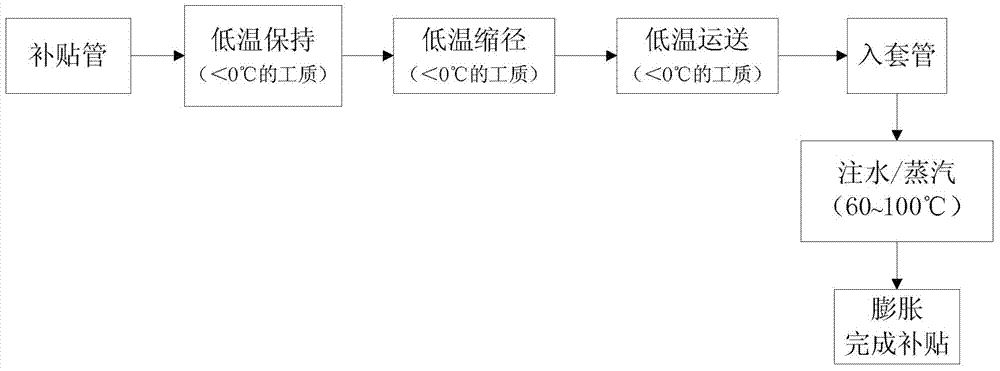

[0078] Embodiment 1: the preparation of subsidy tube

[0079] According to the winter construction conditions in Northeast and Northwest regions, the temperature Ms at which martensitic transformation begins is required to be -20 to -30°C.

[0080] (1) Design alloy composition

[0081] According to the formula Ms (°C)=635-43×Al (mass percentage)-302×Be (mass percentage)-18×Mn (mass percentage)-8×Ga (mass percentage), the mass percentage of each element is calculated as Al: 11%, Be: 0.45%, Mn: 3%, Ga: 0.5%, and the balance is Cu. The calculated Ms(°C) is -27.9°C, which is within the required range; the measured As is 10°C, and the Af is 20-30°C, and the estimated Ms(°C) is approximately -30°C.

[0082](2) According to the designed alloy composition, metal Cu, metal Al, metal Mn, metal Be and metal Ga are added to the argon melting furnace, first vacuumed to 4-5Pa and then filled with argon until the gauge pressure is -0.06MPa, and smelted After heat preservation, it is direc...

Embodiment 2

[0084] Embodiment 2: the preparation of subsidy pipe

[0085] (1) The alloy composition is designed according to the formula, and the mass percentage of each element is Al: 10%, Be: 0.3%, Mn: 2%, Ga: 0.1%, and the balance is Cu.

[0086] (2) Add metal Cu, metal Al, metal Mn, metal Be and metal Ga into a vacuum melting furnace for vacuum melting according to the designed alloy composition. The vacuum degree is 5Pa, and the melting temperature is 1180°C. Cast in high-strength directional solidification equipment into an oxygen-free short thick ingot with a columnar crystal structure, with a diameter of 100mm and a length of about 50mm.

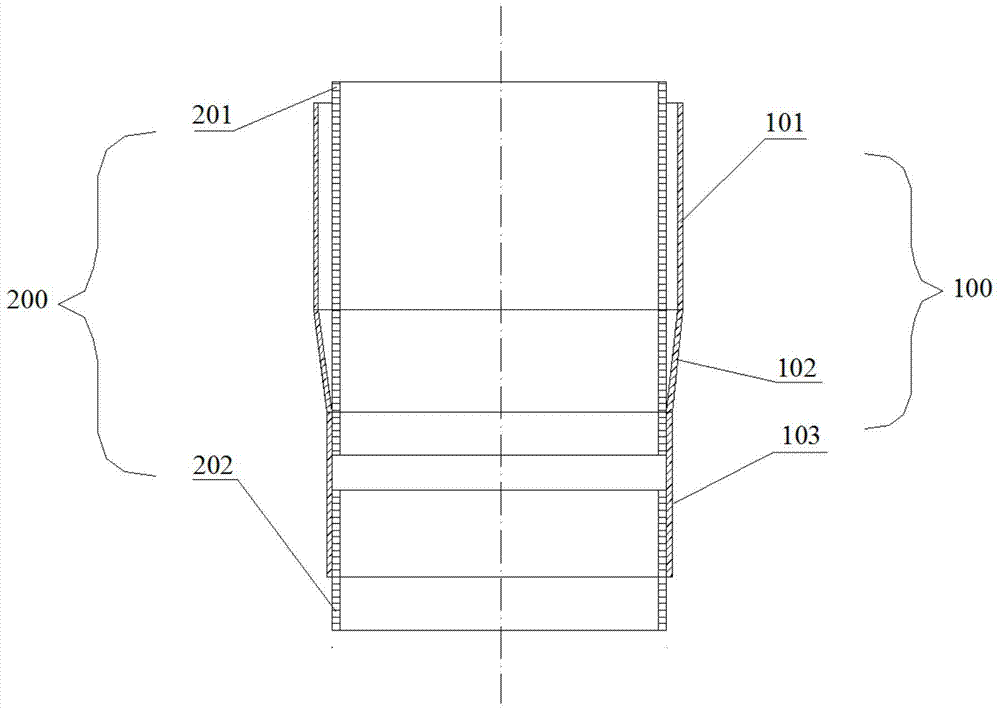

[0087] (3) Thermomechanical treatment: Homogenize the short and thick ingot obtained in step (2) at 840°C for 12 hours and then water-cool to homogenize the alloy composition; then clean it and forge it, the initial rolling temperature is 840°C, The termination temperature is 620°C, and the expansion assembly 100 is obtained; the expansion asse...

Embodiment 3

[0088] Embodiment 3: the preparation of subsidy tube

[0089] Step (1) Design the alloy composition, the mass percentage of each element is the same as in Example 1.

[0090] Adopt vacuum melting in step (2), its vacuum degree is 1Pa, and melting temperature is 1220 ℃, and other steps are all the same as in embodiment 1, and its diameter of obtained ingot is 200mm, is about 200mm long.

[0091] (3) Thermomechanical treatment: the homogenization temperature is 860°C, and the homogenization time is 24h; the initial rolling temperature of hot forging is 820°C, and the termination temperature is 600°C; the setting treatment temperature is 820°C, and the time is 1mm. ; Except that the vacancy treatment temperature is 100° C. and the time is 60 min, other steps are the same as in Example 1. The obtained subsidized pipe has a length of 1-1.3 m and an elastic deformation of 6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com