Membrane tube type falling film evaporator

A falling film evaporator and evaporator technology, applied in evaporator accessories, evaporation, chemical instruments and methods, etc., can solve the problems of liquid film wetting the inner wall of the evaporation tube, affecting the uniform distribution of liquid film, and mutual interference of liquids, etc., to achieve Good sealing, high connection stability, and the effect of reducing energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

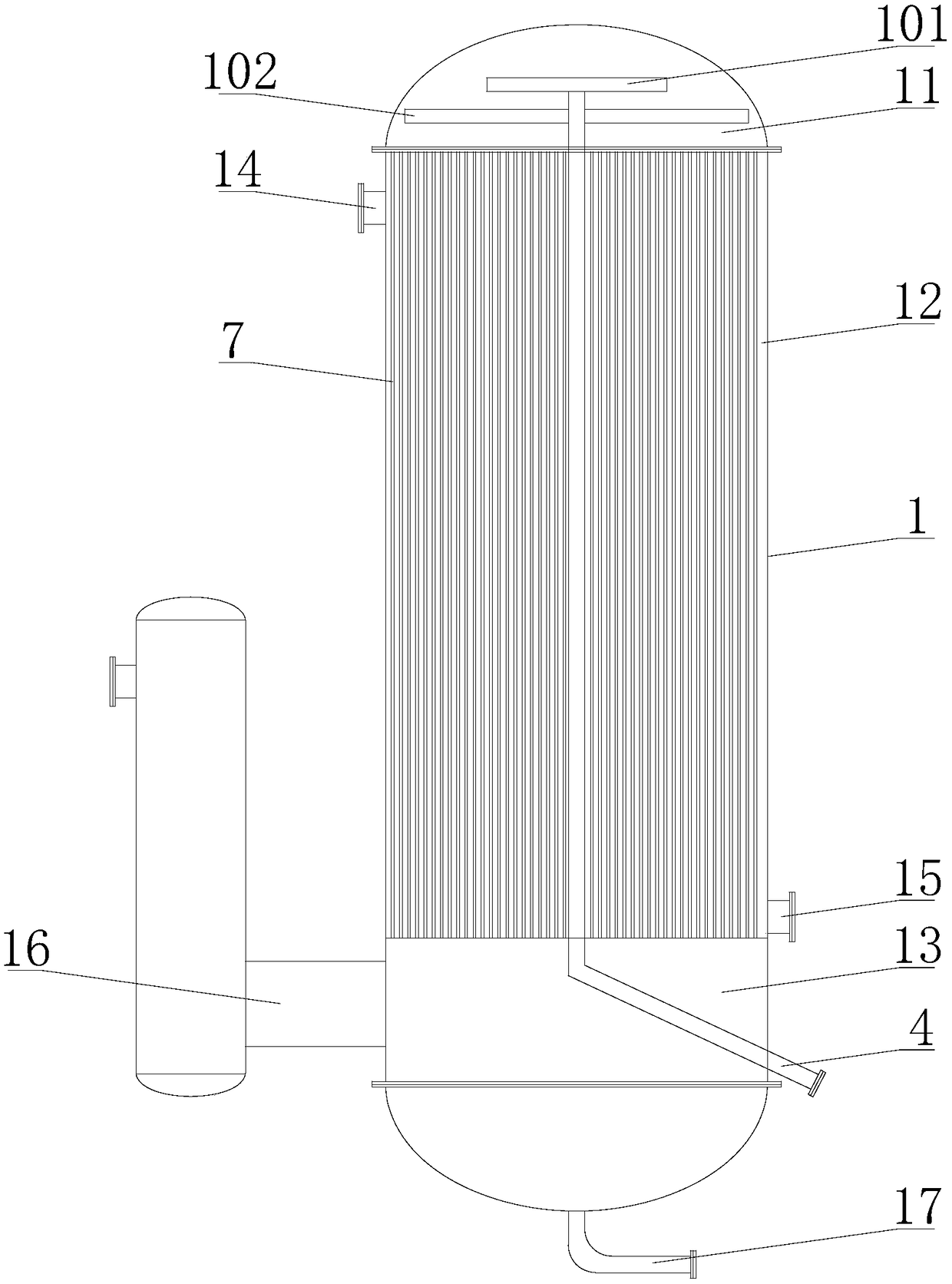

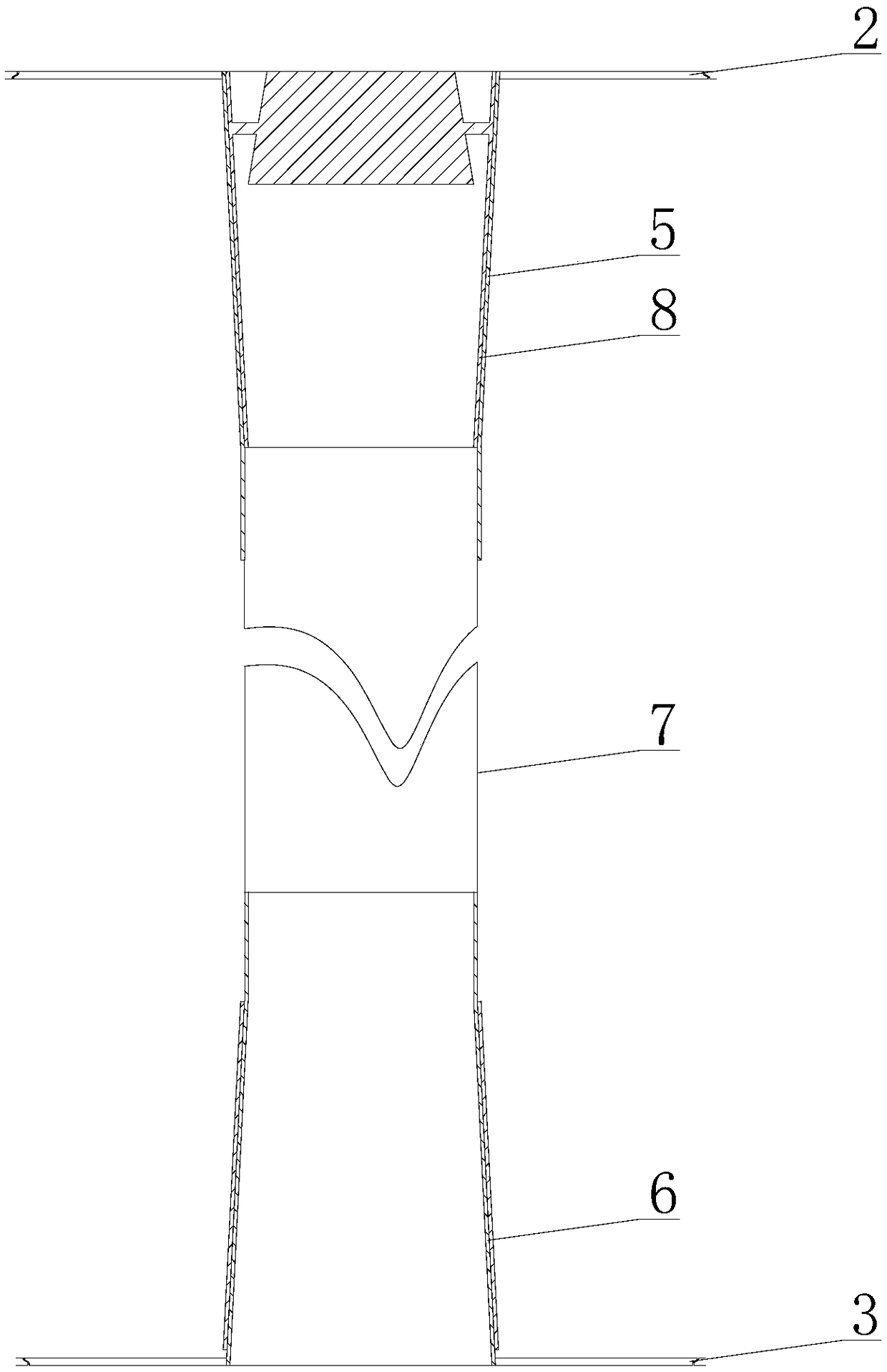

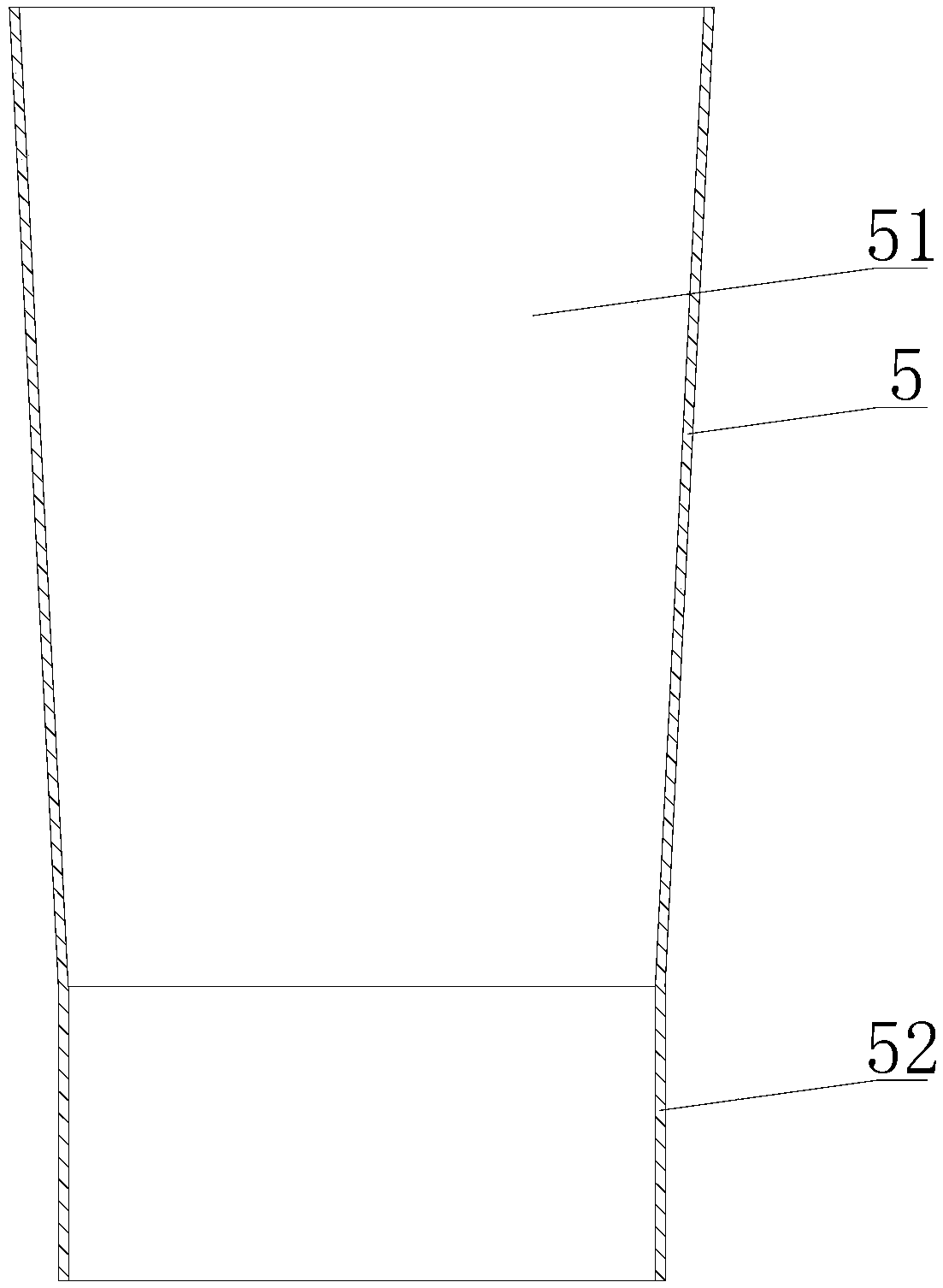

[0031] Such as figure 1 The film tube type falling film evaporator shown includes an evaporator body 1, the evaporator body 1 is provided with an upper partition 2 and a lower partition 3, and the inner cavity of the evaporator body 1 is composed of the upper partition 2 and the lower partition 3 Divided into a liquid inlet chamber 11, a heat exchange chamber 12 and a vapor-liquid separation chamber 13, the evaporator body 1 is provided with a liquid inlet pipe 4 communicating with the liquid inlet chamber 11, and the upper part of the heat exchange chamber 12 is provided with a heating steam inlet 14 , The lower part is provided with a condensed water outlet 15, the upper part of the vapor-liquid separation chamber 13 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com