Multilayer composite patterned stainless steel and its mfg. method

A technology of multi-layer compounding and manufacturing methods, which is applied in the direction of chemical instruments and methods, layered products, metal rolling, etc., can solve the problems of difficult pattern making, high labor intensity, poor corrosion resistance, etc., and achieve a wide range of applications and pattern Clear and beautiful effect with low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Describe in detail below in conjunction with accompanying drawing and embodiment:

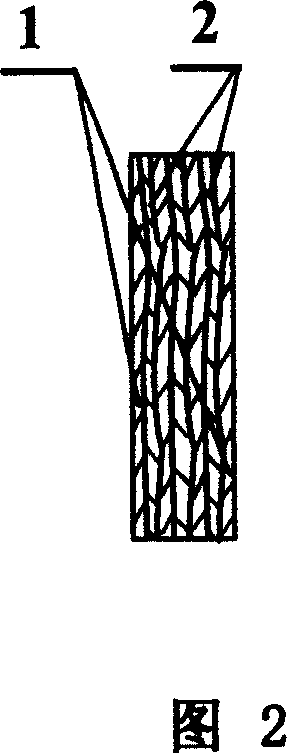

[0014] Fig. 2 is a kind of multi-layer composite stainless pattern steel used for making utensils, which is composed of multi-layer stainless steel layers 1 and nickel metal layers 2 arranged between the stainless steel layers 1.

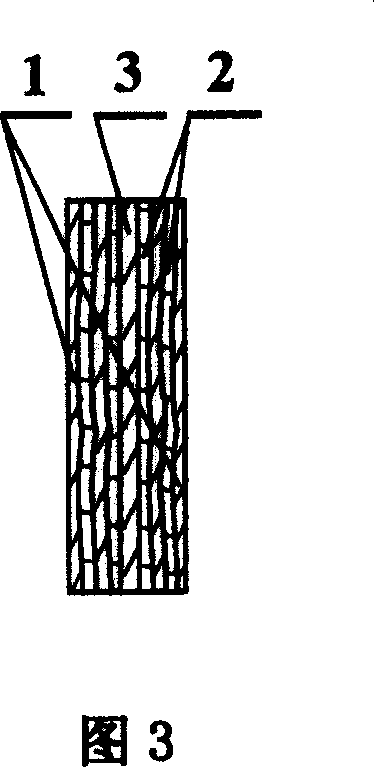

[0015] Fig. 3 is a kind of multi-layer composite stainless pattern steel for making knives. In order to sharpen the edge of the knife, a layer of stainless steel blade steel layer 3 is provided in the stainless steel layer 1 . For making blade can be arranged on the center of cutter body, the stainless steel layer 1 in the center is stainless blade steel layer 3.

[0016] In order to facilitate the production of rich, colorful, changeable, beautiful and clear patterns on the two surfaces of the multi-layer composite stainless pattern steel through deep grinding, digging, drilling and other processes, it is best to use at least 11 metal layers The multi-layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com