Low-temperature waste heat treatment method for dry tail gas

A technology of low-temperature waste heat and treatment methods, which is applied in the directions of dry gas arrangement, separation methods, chemical instruments and methods, etc., to achieve the effect of heat energy upgrading and conversion, and process optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

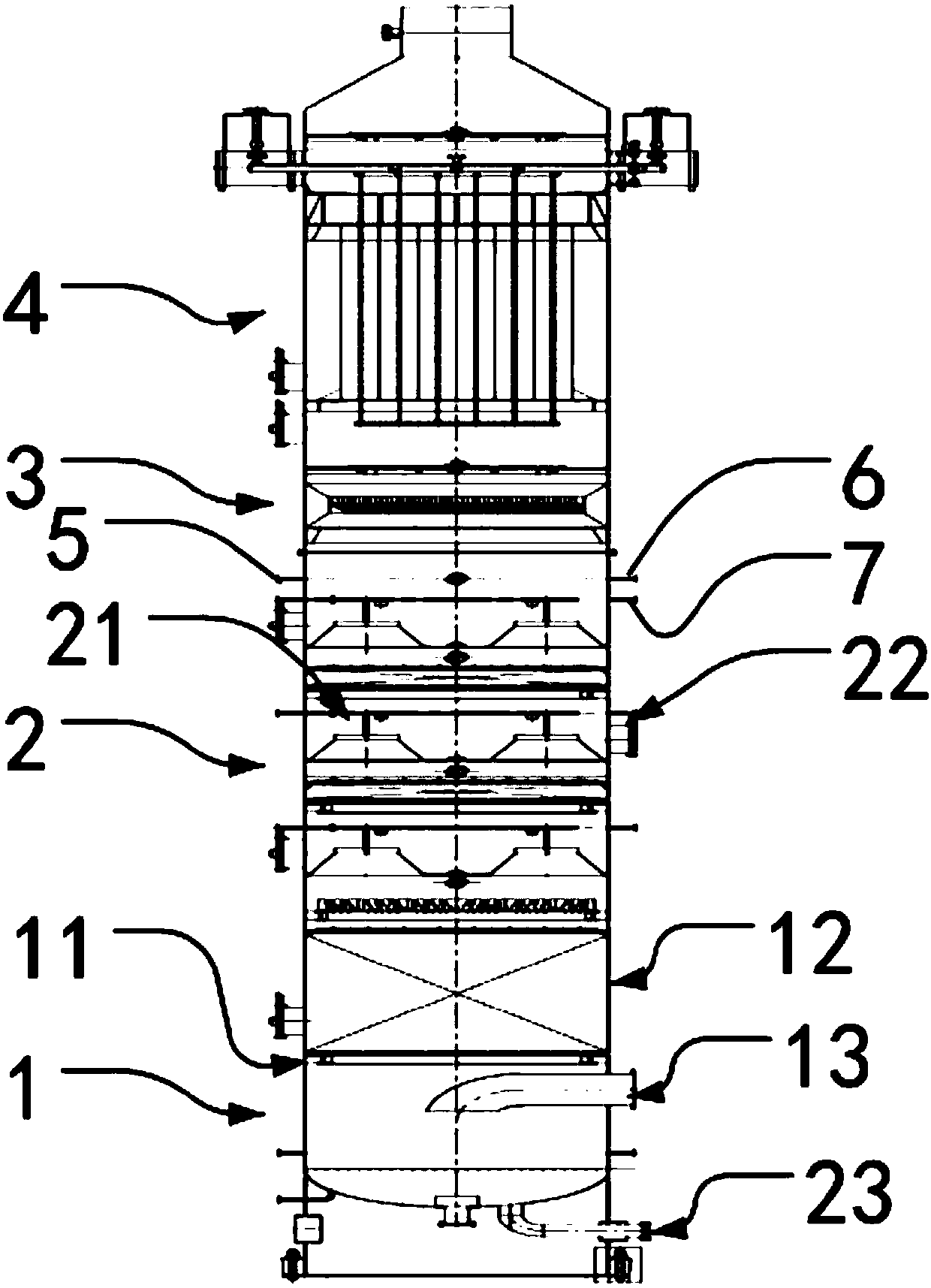

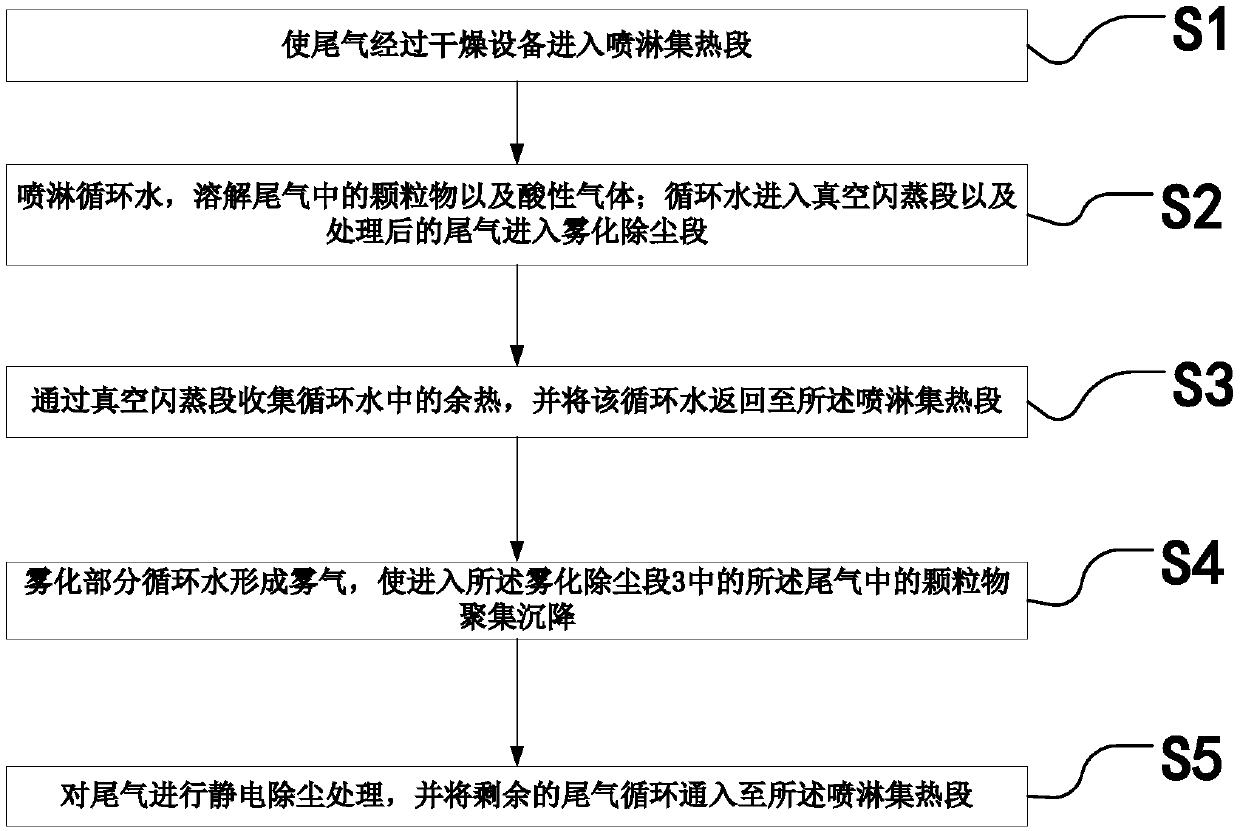

[0035] Embodiment: A low-temperature waste heat treatment equipment for drying tail gas, including a tail gas treatment chamber, the tail gas treatment chamber is sequentially provided with a vacuum flash section 1, a spray heat collection section 2, an atomization dust removal section 3, Electrostatic precipitator section 4.

[0036] In this embodiment, the spray heat collecting section 2 includes at least one layer of spray washing mechanism, the tail gas passes through the spray washing mechanism from bottom to top, and the spray washing mechanism sprays and washes the tail gas , heat is enriched through the circulating water.

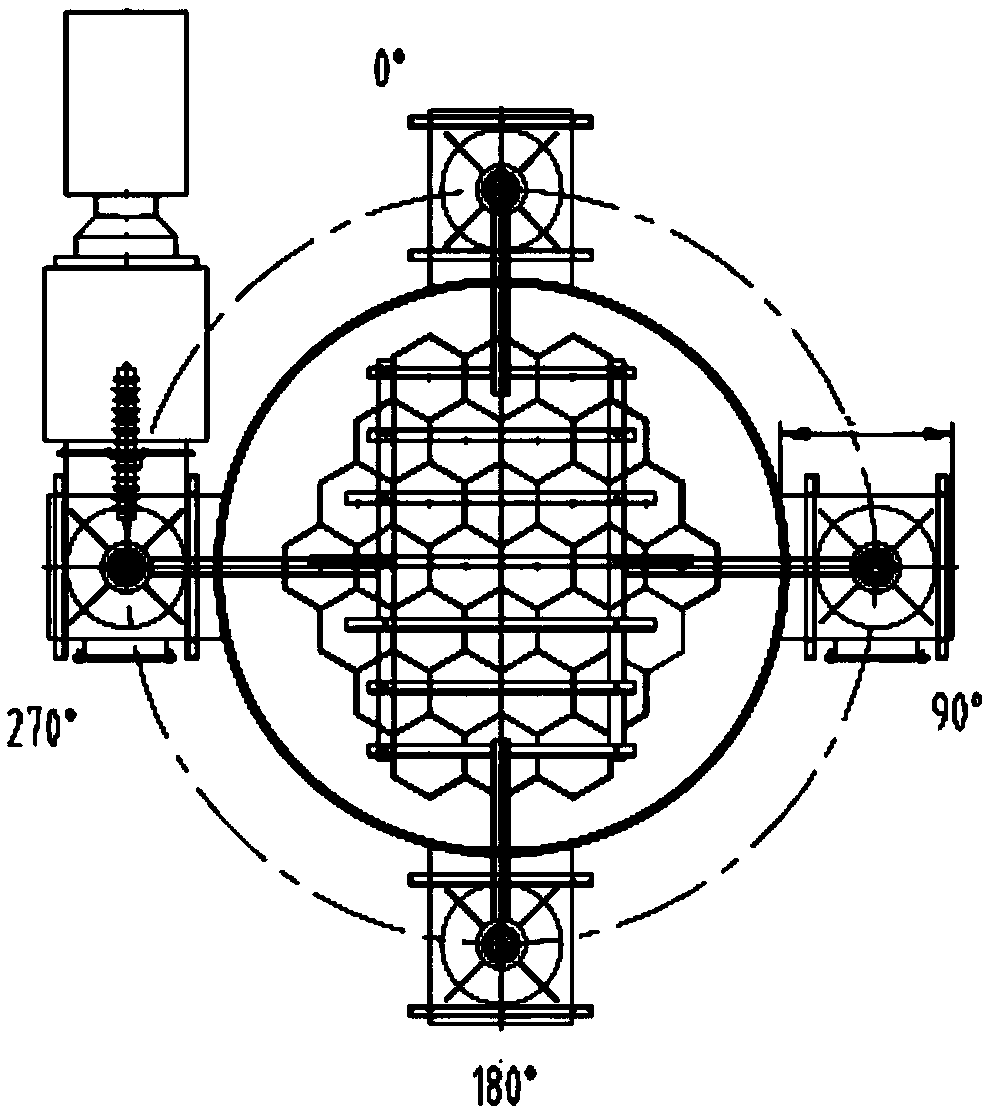

[0037] In this embodiment, the spray washing mechanism in the spray heat collecting section 2 has three layers, and each layer of the spray washing mechanism includes a plurality of nozzles 21 , a liquid inlet 22 and a liquid outlet 23 . Wherein, the nozzle 21 is arranged on the cavity wall of the exhaust gas treatment chamber and is arranged aroun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com