Anaerobic reactor for vinasse wastewater treatment

An anaerobic reactor and wastewater treatment technology, which is applied in the field of anaerobic reactors, can solve problems such as insufficient and comprehensive adsorption and decomposition, slow wastewater treatment efficiency, and increased use costs, so as to improve digestion reaction efficiency, enhance mixing effect, shorten The effect of reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

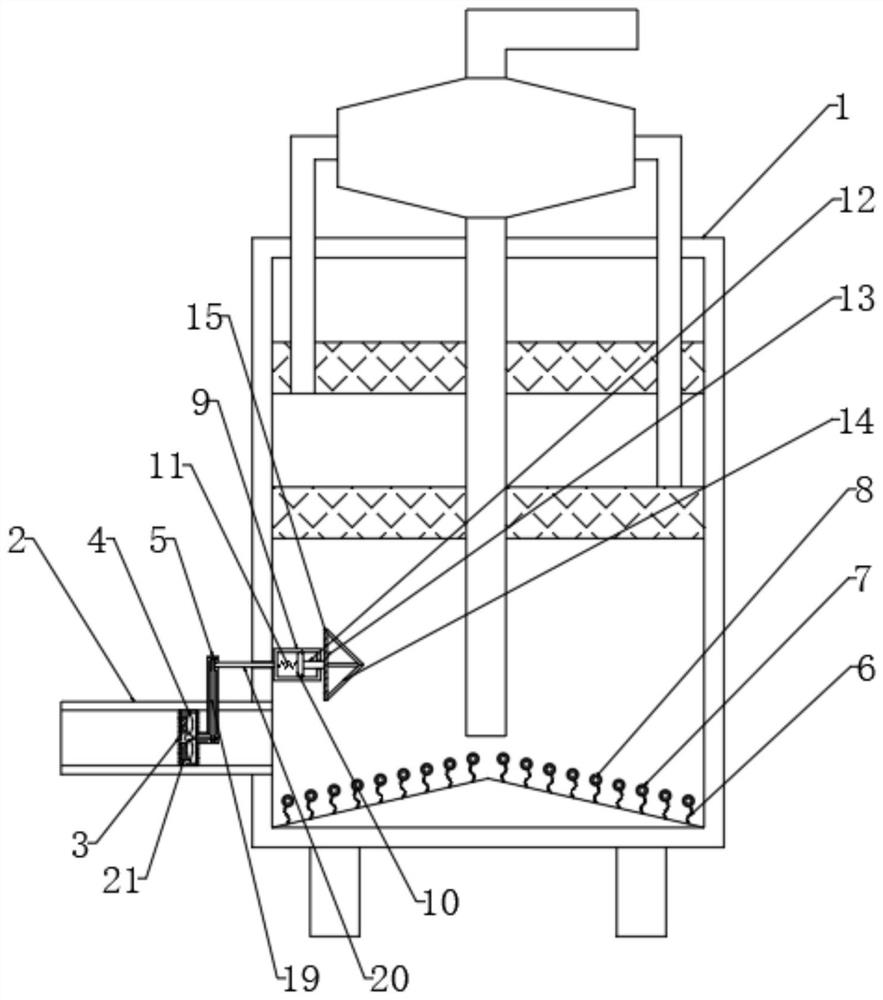

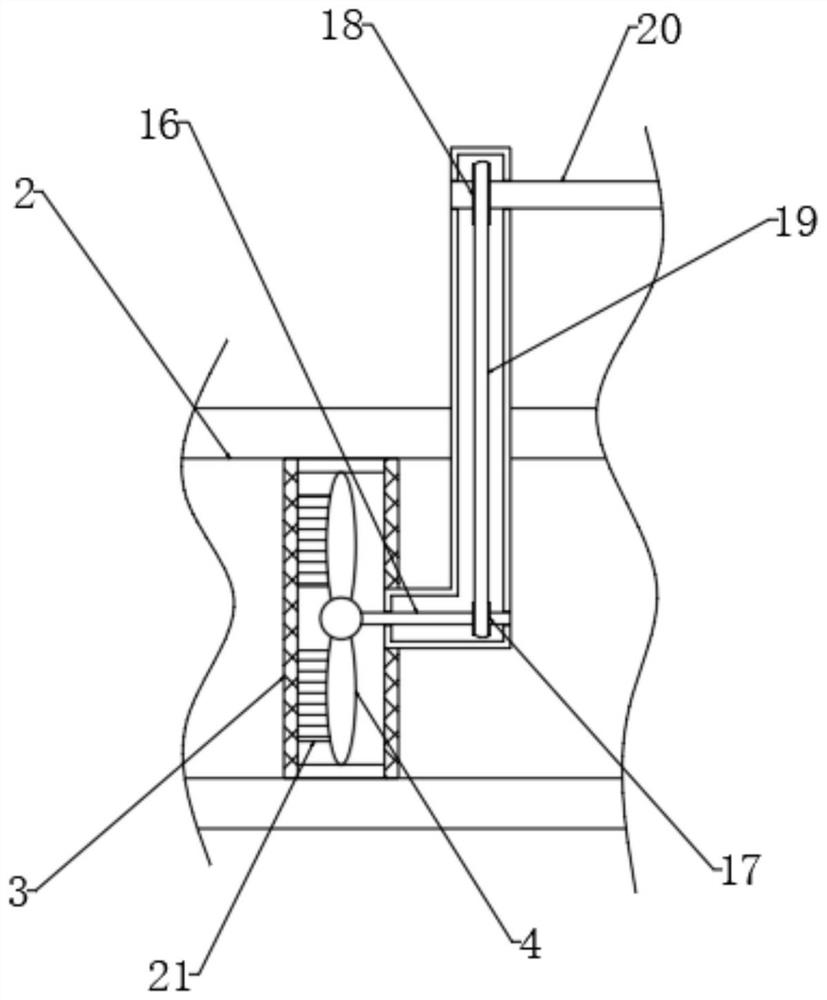

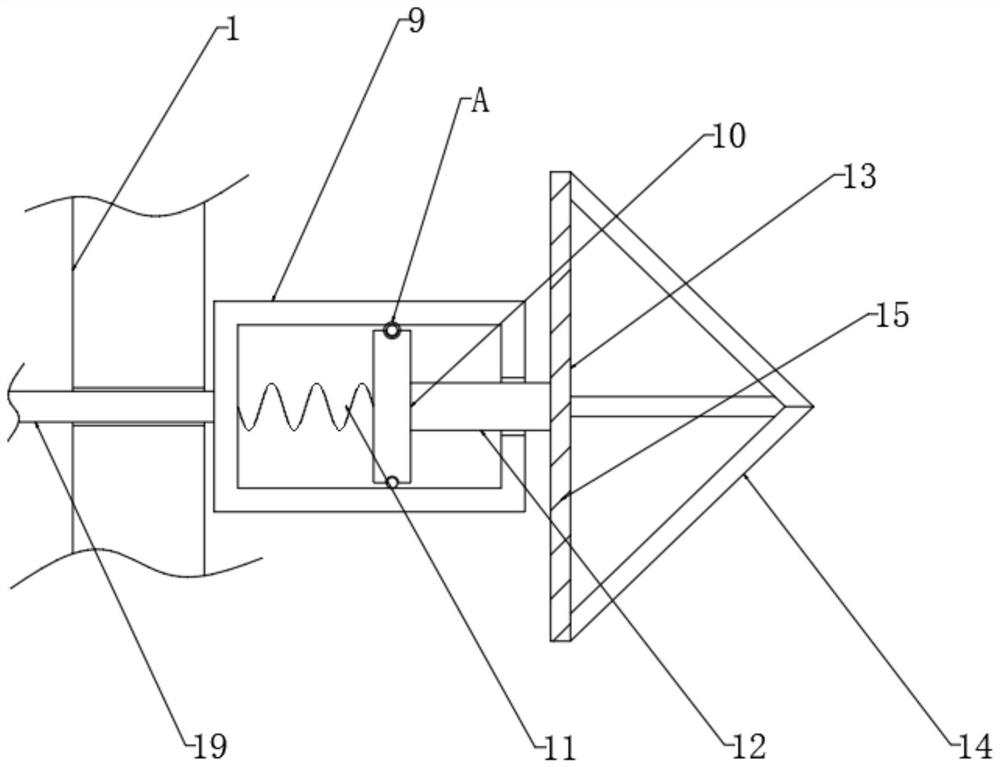

[0040] see Figure 1-6 , an anaerobic reactor for wine tank wastewater treatment, comprising an anaerobic reactor body 1, the left end of the anaerobic reactor body 1 is fixedly connected with a water inlet pipe 2, and the water inlet pipe 2 is connected to the inside of the anaerobic reactor body 1 The inside of the water inlet pipe 2 is fixedly connected with the filter screen frame 3, the inside of the filter screen frame 3 is hollow, the inside of the filter screen frame 3 is equipped with flow paddles 4, and the right end of the filter screen frame 3 is fixedly connected with a connecting frame 5. The connecting frame body 5 runs through the filter screen frame 3, and the upper end of the connecting frame body 5 runs through the water inlet pipe 2 and extends to its upper side. The inner bottom end of the anaerobic reactor body 1 is fixedly connected with a plurality of evenly distributed connecting ropes 6. The upper end of the connecting rope 6 is fixedly connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com