Corrosion-resistant hose assembly for swill collection vehicle

A hose assembly and corrosion-resistant technology, applied in the directions of hoses, hose connecting devices, pipes, etc., can solve the problems of increasing the maintenance cost of swill collection vehicles, inconvenient collection operations, and high corrosiveness of swill, and is conducive to production and promotion. Application, strong corrosion resistance, the effect of reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

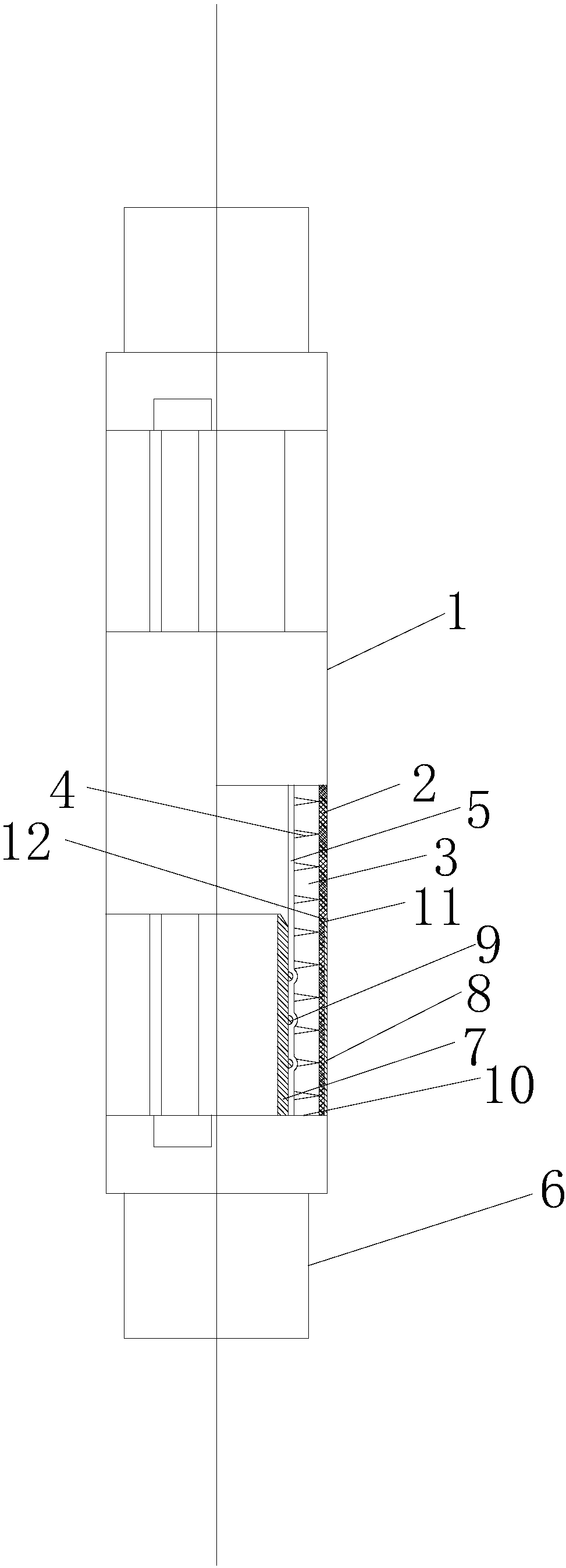

[0013] refer to figure 1 , a corrosion-resistant hose assembly for a swill collection vehicle according to the present invention, comprising a hose body 1, a wire mesh layer 2, a rubber hose layer 3, a spring shaping layer 4, a corrosion-resistant coating layer 5, a pipe joint body 6, an inner Core tube 7, shrinkable outer tube 8, the hose body 1 is sequentially provided with a corrosion-resistant coating layer 5, a spring shaping layer 4, a rubber hose layer 3, and a wire mesh layer 2 from the inside to the outside, and the wire mesh layer 2 braided and coated on the outer surface of the rubber hose layer 3, the spring shaping layer 4 is arranged in the rubber hose layer 3, the corrosion-resistant coating layer 5 is arranged on the inner surface of the rubber hose layer 3, and the pipe joint body 6 is provided with The inner core tube 7 and the shrinkable outer tube 8, the two ends of the hose body 1 are sleeved on the inner core tube 7, the shrinkable outer tube 8 is fixedly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com