Radio frequency coaxial electric cable for mobile communication and method for manufacturing

A radio frequency coaxial cable, mobile communication technology, applied in the direction of manufacturing coaxial cables, coaxial cables/analog cables, circuits, etc., can solve the problem of transmission attenuation and increase of voltage standing wave ratio, increase of transportation and packaging costs, impact Cable performance indicators and other issues to achieve the effect of ensuring mechanical properties, making up for cost increases, and reducing the amount of copper used in the inner conductor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

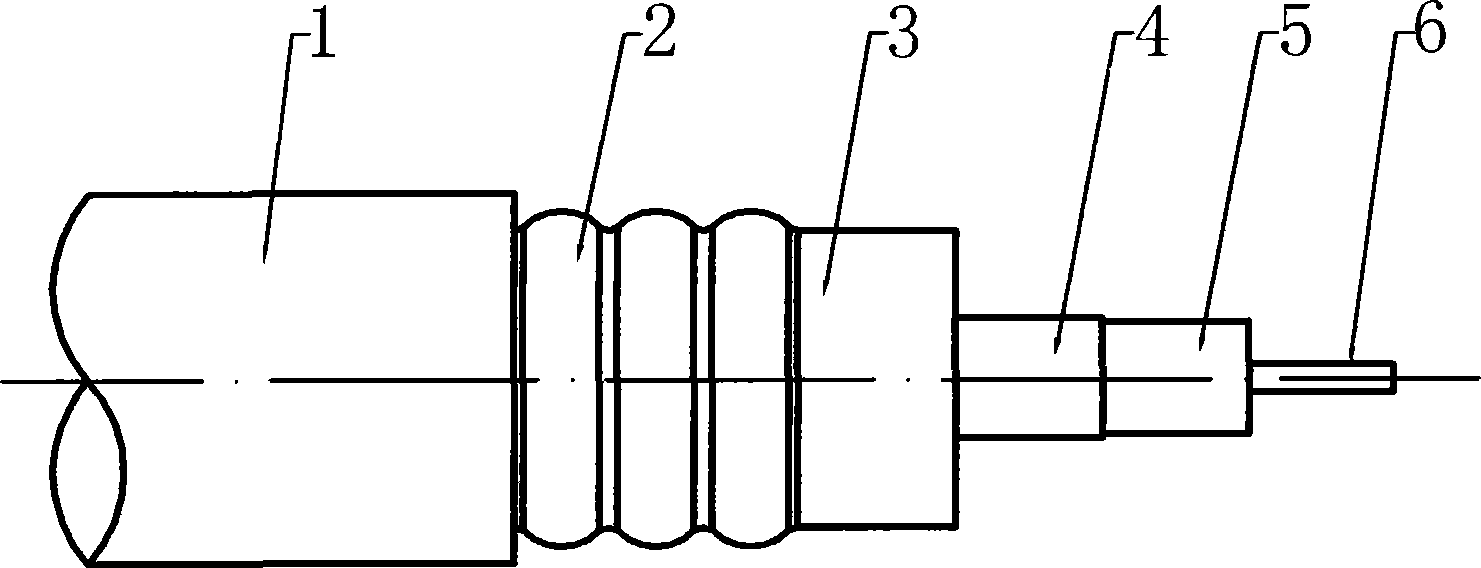

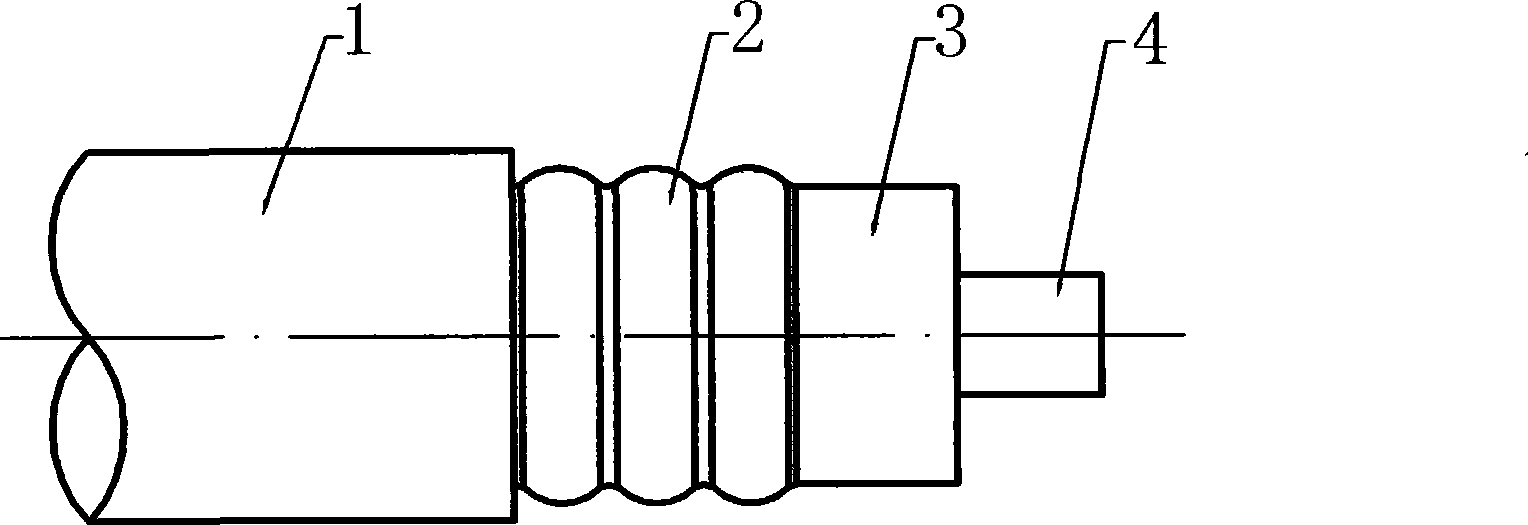

[0017] Example: see figure 1 , the radio frequency coaxial cable for mobile communication of the present invention, by central copper-clad aluminum wire 6 (commercially available), forms support body 5 by extrusion foaming, is 0.23mm (7 / 8″ cable) thin copper strip, and argon arc welding to form a smooth inner conductor 4, extruded foam insulation layer 3 outside the inner conductor, outer longitudinal welding, embossed into a crepe tube outer conductor 2, and finally extruded outer sheath 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com