Cutting switch

A technology for cutting off switches and contacts, applied in the field of automotive power switches, can solve problems such as easy failure, inability to meet requirements, equipment damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Preferred embodiments of the present invention will be described below with reference to the accompanying drawings. In the referenced drawings, the same reference numerals are used for the same or similar components in different drawings.

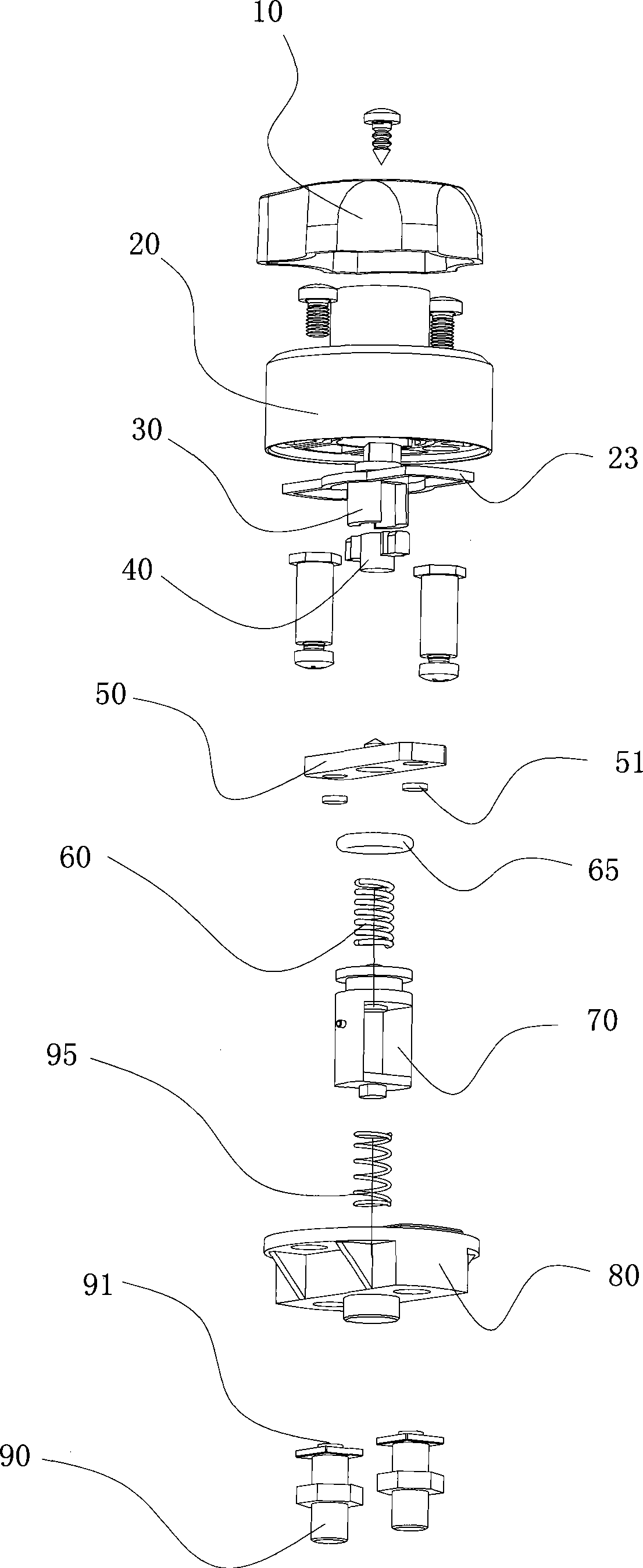

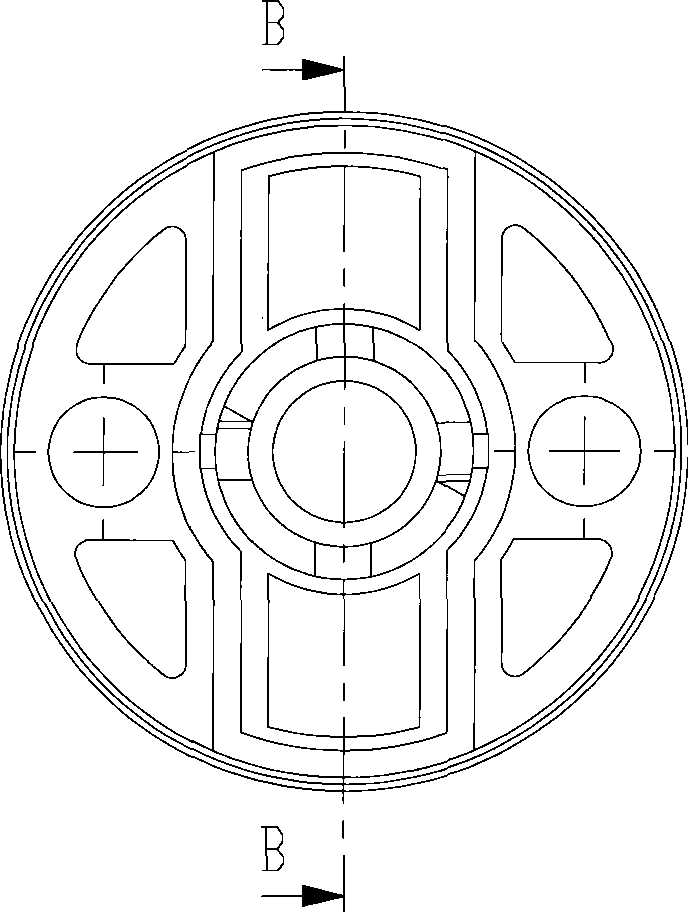

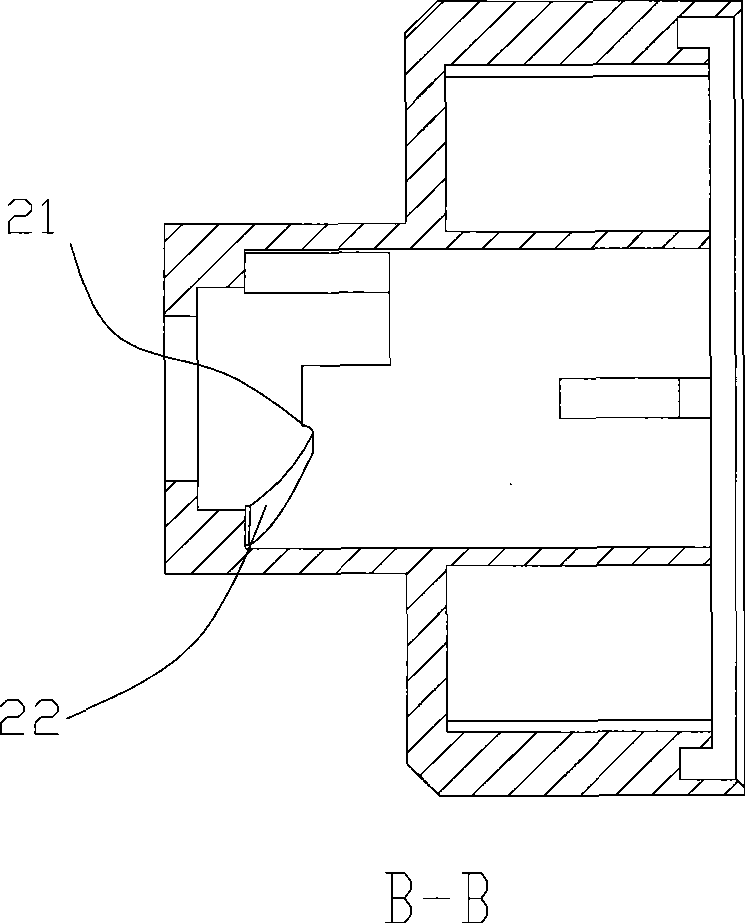

[0013] see figure 1 , is a schematic diagram of the explosion structure of the cut-off switch in the embodiment of the present invention. The cut-off switch includes: a handle 10, a propulsion device connected to the handle 10, the propulsion device includes a housing 20, a rotating shaft (not shown) installed inside the housing 20, the rotating shaft cooperates with the chute 30, and the slider 40 Card is located in the chute 30, and the housing 20 is provided with a slope 22 (such as Figure 2b ), the slope surface 22 is tightly pressed against the slide block 40, and the slope of the slope surface 22 gradually transitions from low to high, and the highest point 21 of the slope surface 22 (such as Figure 2b ) is provided with a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap