LED driving circuit and secondary side controller thereof

A light-emitting diode and secondary-side control technology, which is applied to semiconductor devices of light-emitting elements, circuit layout, lamp circuit layout, etc., can solve problems affecting the accuracy of dimming control, increase, and increase the cost of light-emitting diode drive circuits, etc., to achieve Avoid excessive voltage stress or inaccurate dimming control, cost simplification, and reduce electromagnetic interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

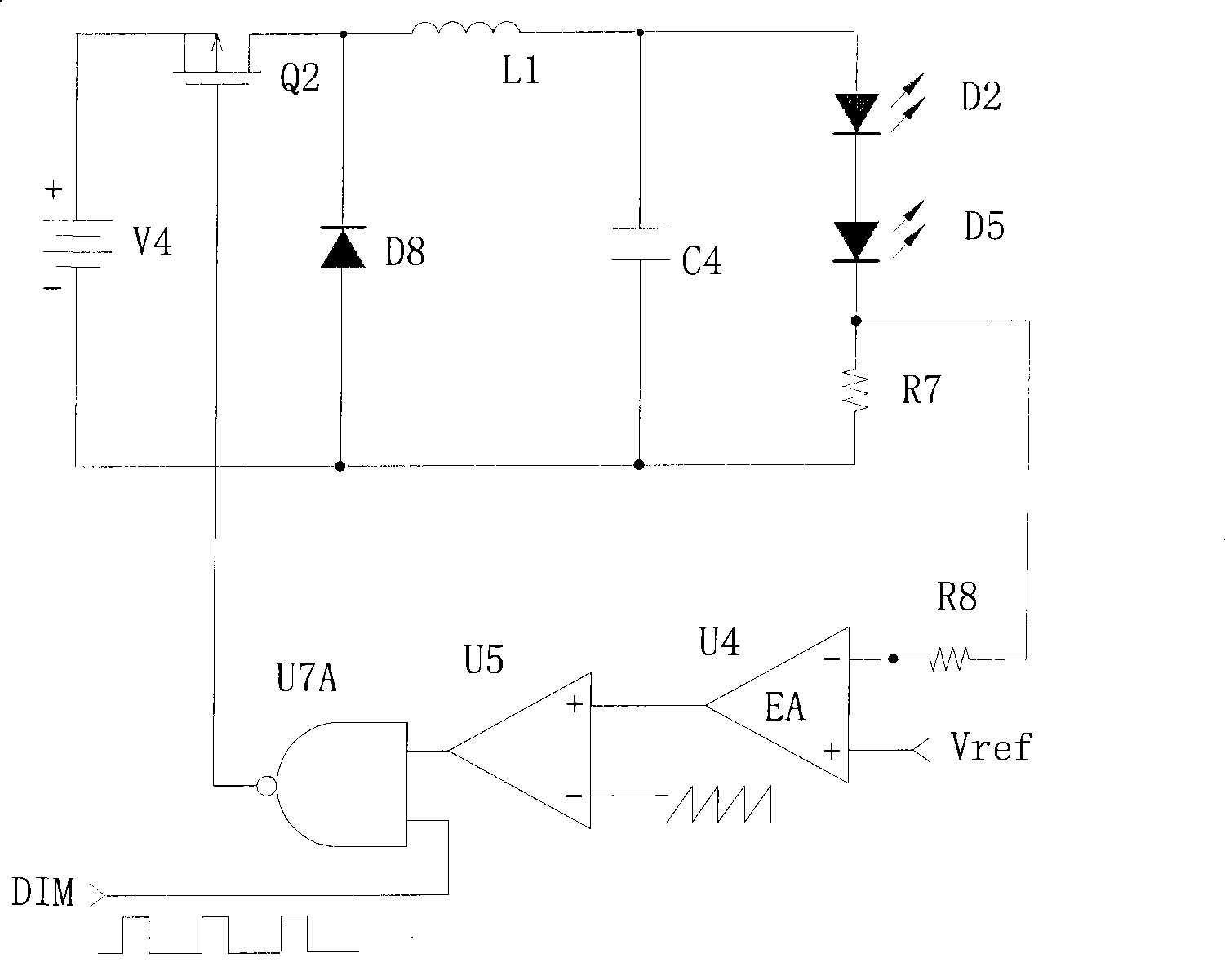

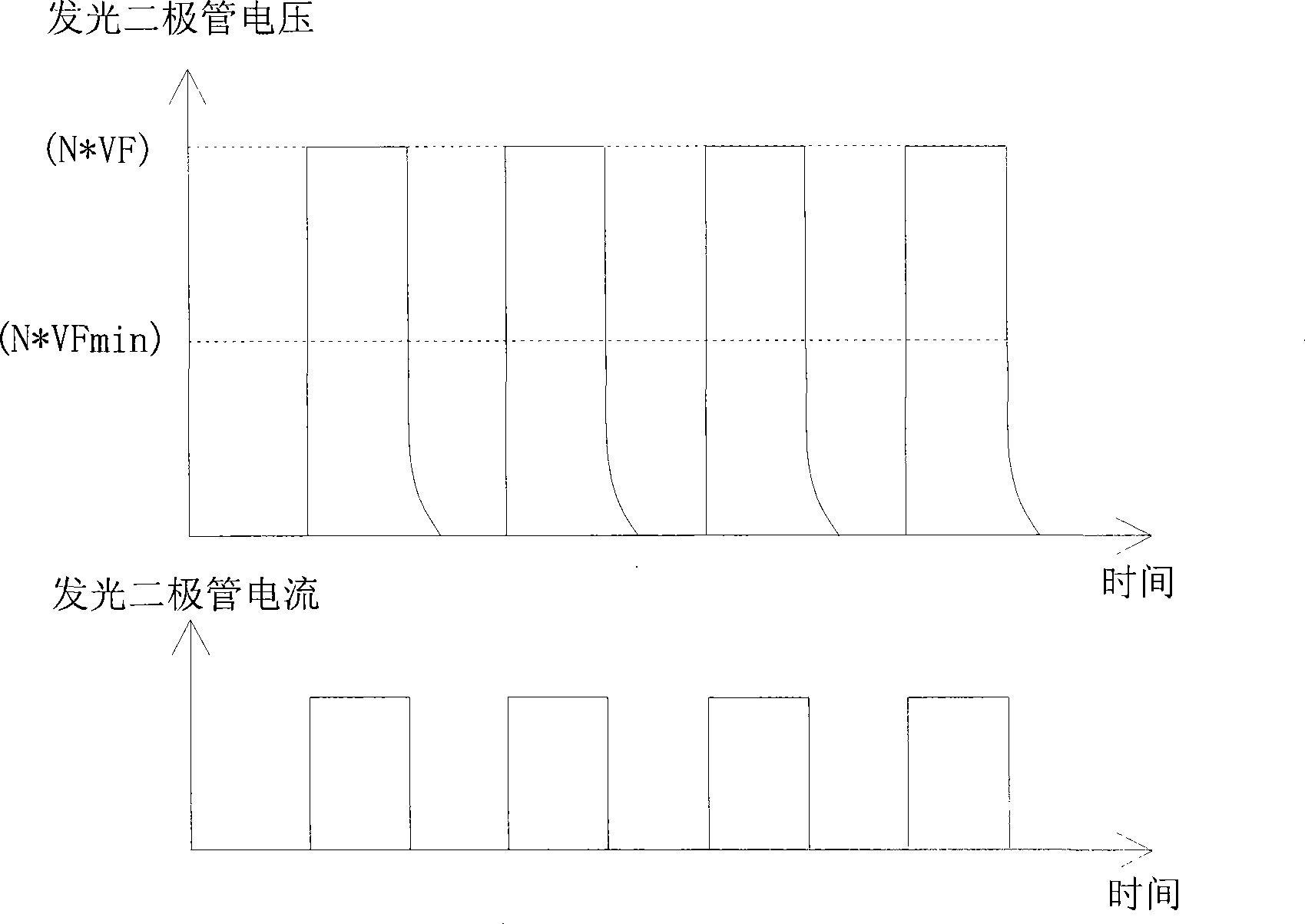

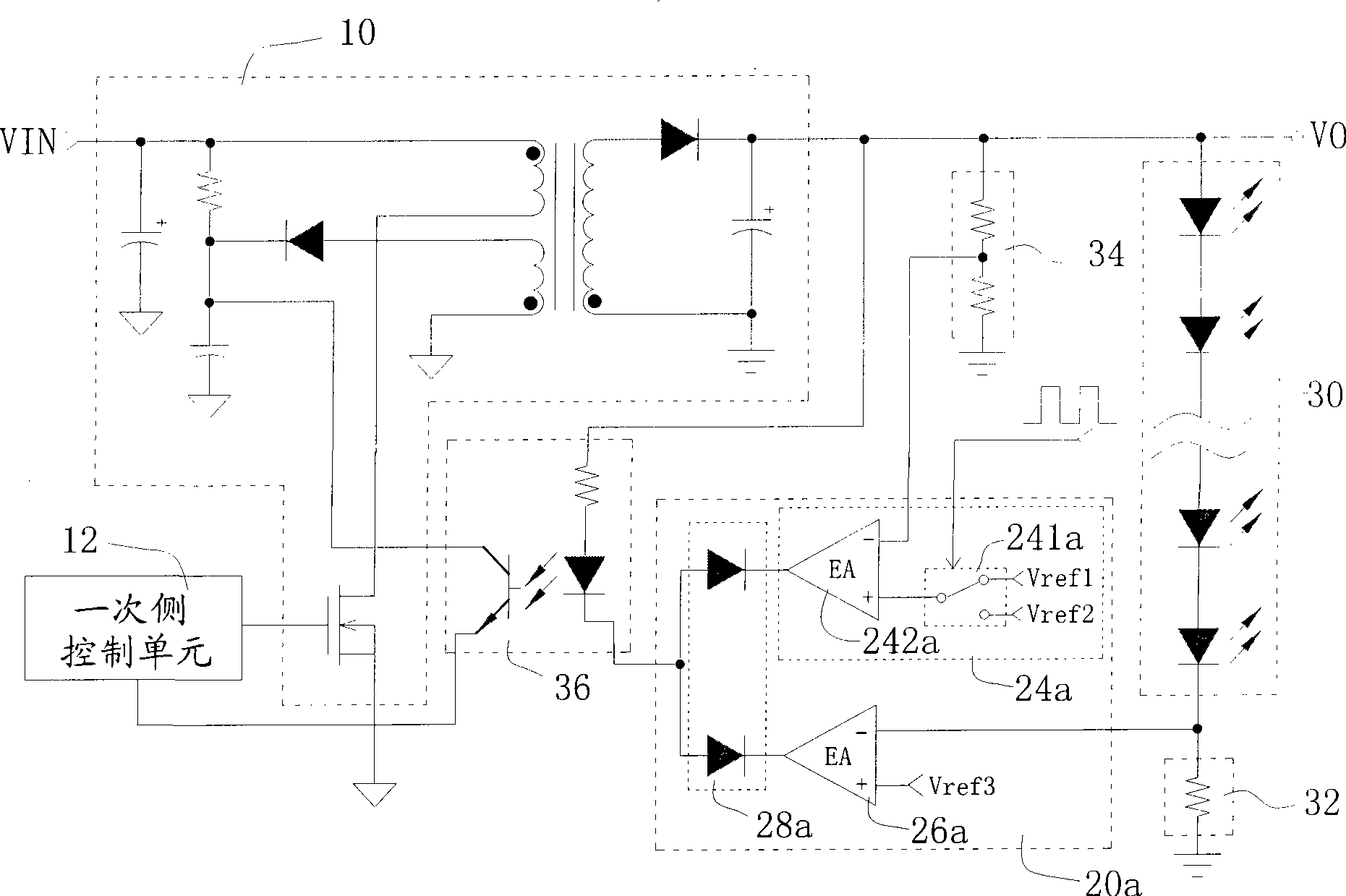

[0031]The feature of the present invention is that in the dimming control process, the output voltage of the LED driving circuit is controlled at a first driving voltage or a second driving voltage. When the output voltage is at the first driving voltage, the light-emitting diode module is under current feedback control, so it is in a stable light-emitting state; and when the output voltage is at the second driving voltage, it is under voltage feedback control, so the output voltage is approximately equal to the light-emitting diode module The critical voltage of the LED module (but greater than zero volts) makes the LED module hardly emit light, preferably slightly lower than the critical voltage of the LED module to ensure that the LED module does not emit light. In this way, during the dimming process, the voltage change applied to the LED module is smaller than the existing voltage change, so that the problems of the LED being subjected to excessive voltage or inaccurate di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com