Sliding type double-cohesion step-by-step driven bottle blowing machine

A step-driven, sliding technology, applied in the field of blow molding machines, can solve the problems of easy stretching and deformation use cost, many rotating connection points, easy to produce wear, etc. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

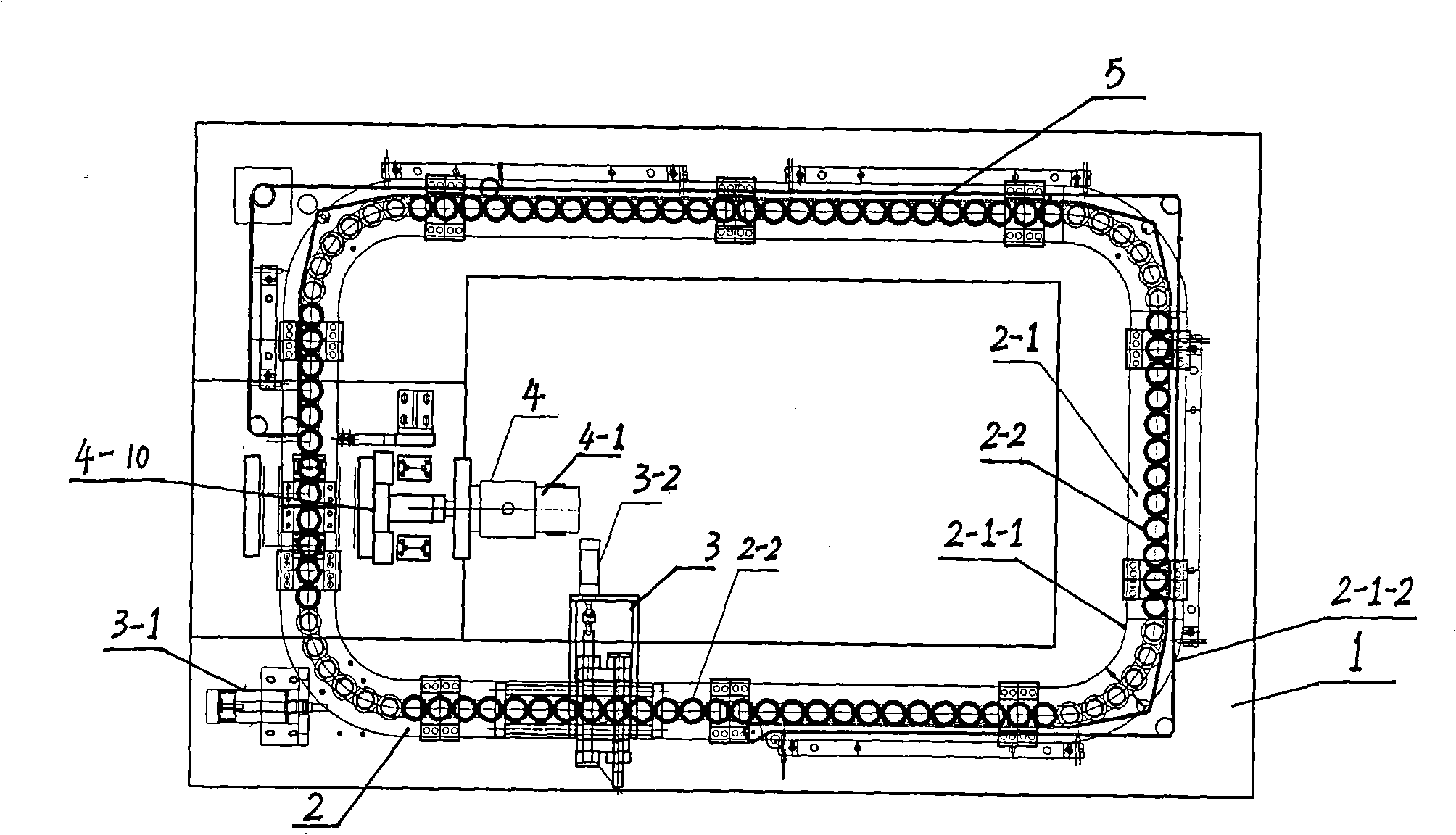

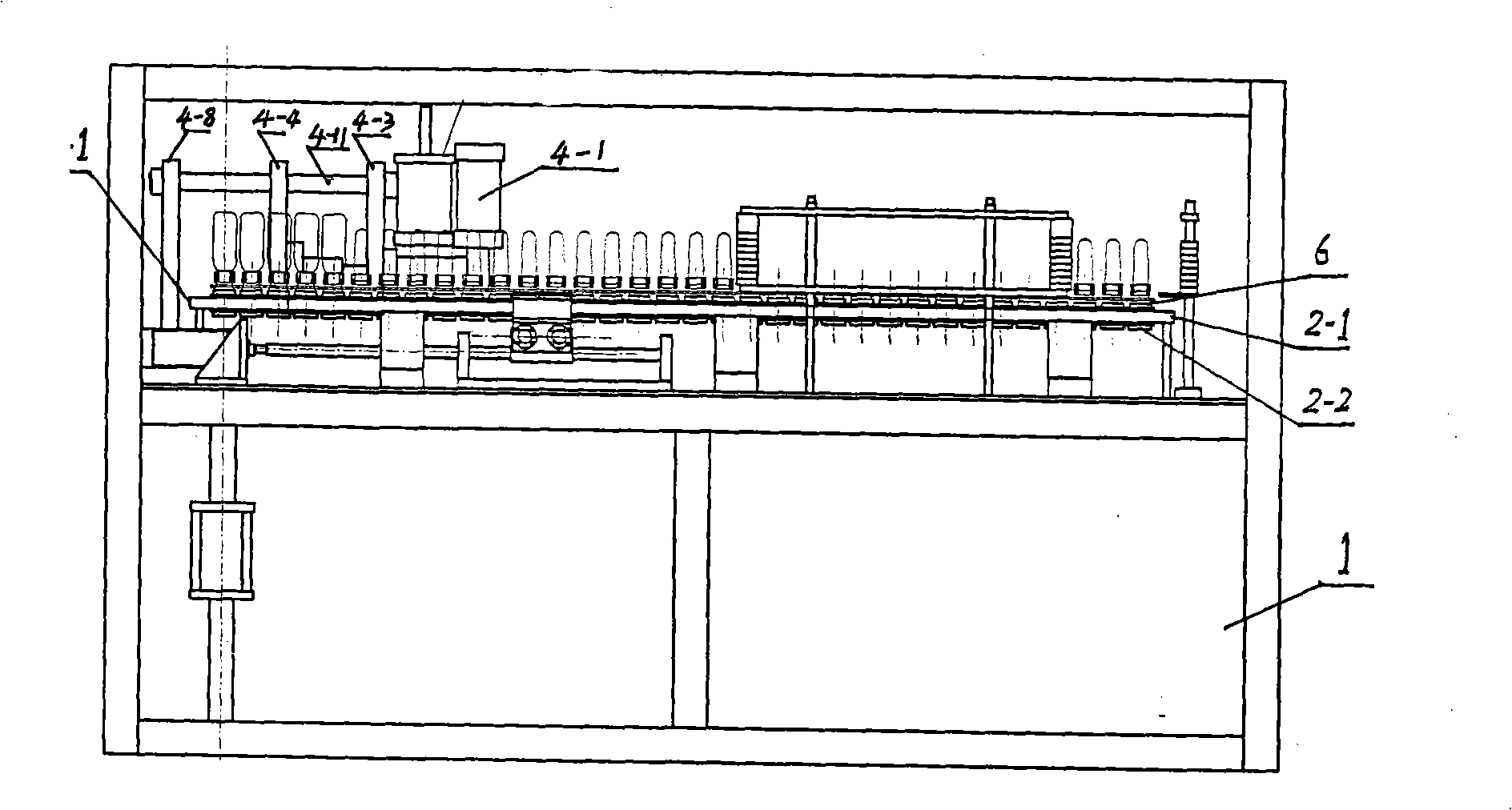

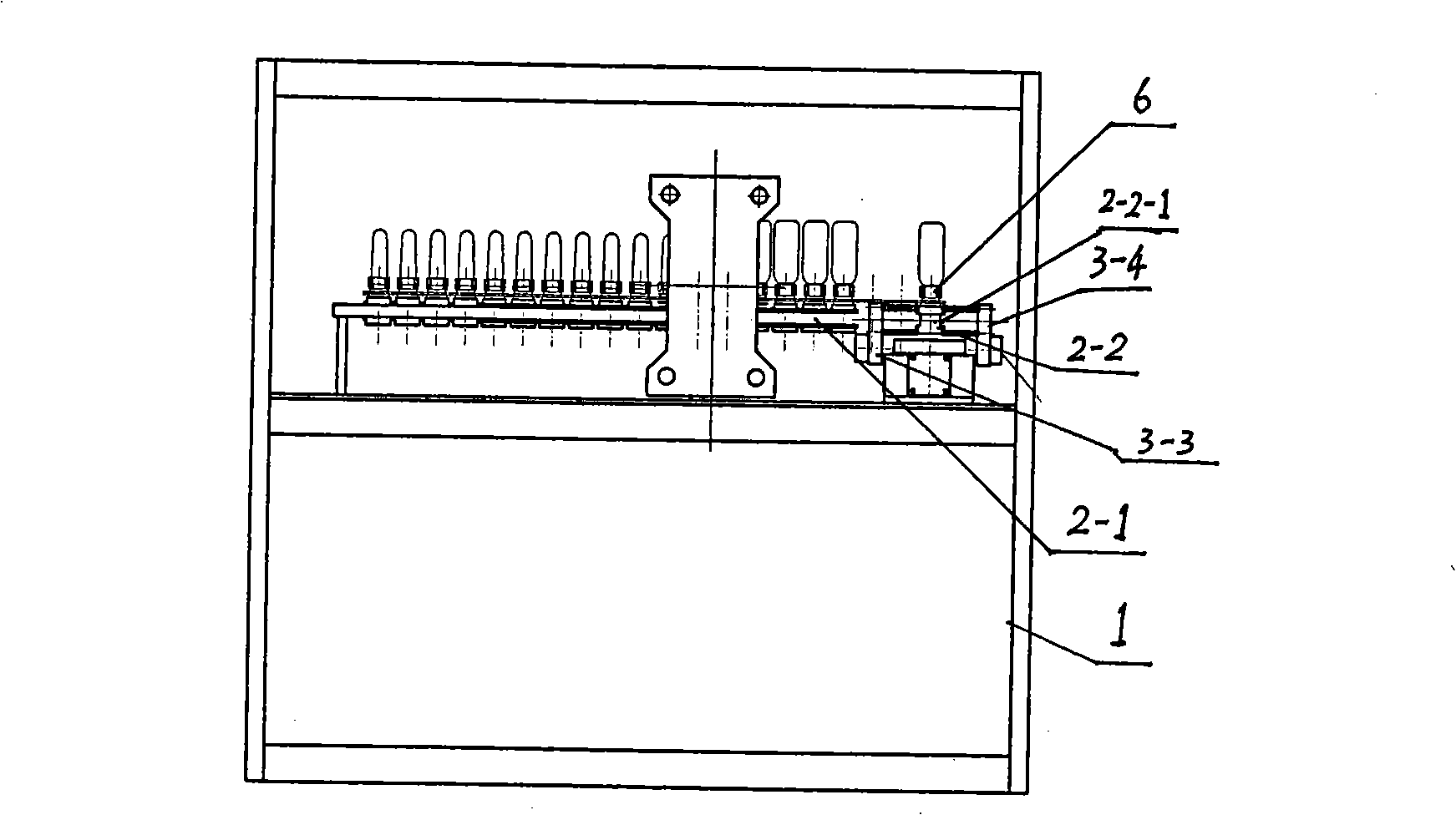

[0029] Figure 1 to Figure 8 Constitute the specific embodiment 1 of the present invention.

[0030] refer to Figure 1 to Figure 8 , the present embodiment includes a frame 1, a preform holder conveying device 2, a driving device 3, a clamping device 4 and a heating system 5; Constituted with the slider 2-2, the ring slide rail 2-1 includes the inner slide rail 2-1-1 and the outer slide rail 2-1-2, and the slider 2-2 is set on the inner slide rail 2-1 and the outer slide rail Between the rails 2-2, the slide block 2-2 is provided with a preform seat or an interface connected with the preform seat; the slide block 2-2 is slidably connected with the ring slide rail 2-1 and can -1 Inner progressive sliding or stepping sliding; the driving device 3 is a double-embracing stepping pneumatic driving structure, including a stepping pneumatic driving mechanism and a double-embracing grasping mechanism, and the stepping pneumatic mechanism includes a stepping cylinder 3-1 and The po...

specific Embodiment 2

[0039] The feature of this embodiment is that the slider 2-2 can be provided with a preform holder, and also can be provided with an interface connected with the preform holder, through which the slider 2-2 can be connected with the preform holder. The slider 2-2 can be in the shape of a cylinder or a cylinder, and can also be in the shape of a square or a rib, and the groove 2-2-1 on the outer surface of the slider 2-2 is an annular groove. All the other are with specific embodiment 1.

specific Embodiment 3

[0040] The characteristics of this embodiment are: in the driving device 3, one, three, four, five, eight or more than ten arc-shaped concave positions can be respectively placed on the claw 3-3 and the claw 3-4 as required, each One or more preform seats can be picked up by double-holding at the same time. To achieve the purpose of convenience, flexibility and production efficiency. All the other are with specific embodiment 1.

[0041] In the present invention, the cylinder in the driving device 3 can include a stepping cylinder positioning cylinder, using compressed air (0.6-0.8Mpa) as a power source, and driving two claws to close in the middle after one of the air inlets of the positioning cylinder enters, Hold the heating seat tightly; step into one of the air inlets of the cylinder and push the two claws to hold the heating seat tightly and step forward, two stations at a time. The two claws are separated after the second air intake of the positioning cylinder, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com