Floor board support member and floor board structure

A technology of supporting parts and supporting components, which is applied in the field of floor supporting parts, can solve the problems of higher height of floor supporting parts and larger interference range of mass bodies, etc., and achieve the effect of narrowing the interference range and good partition performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

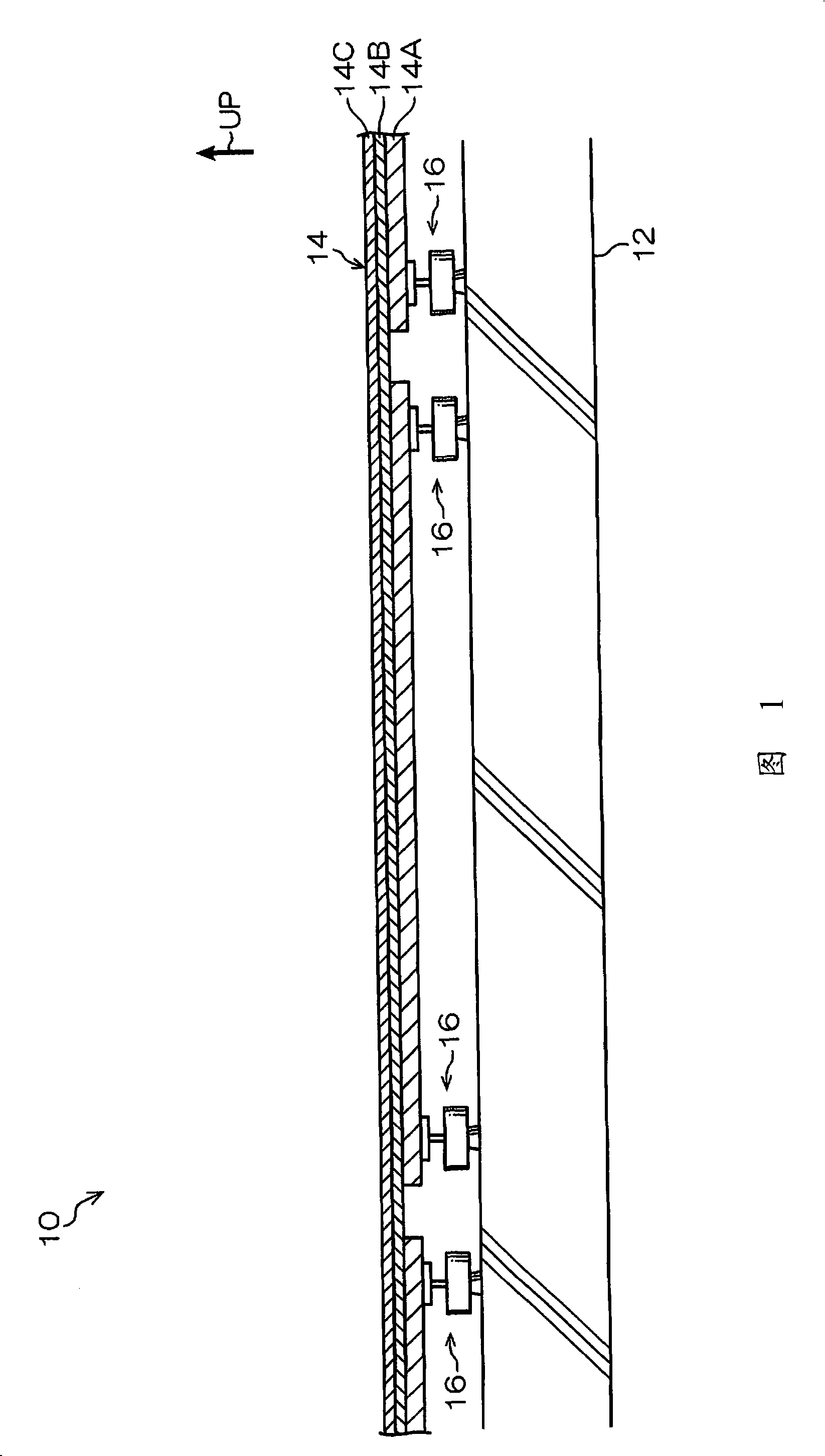

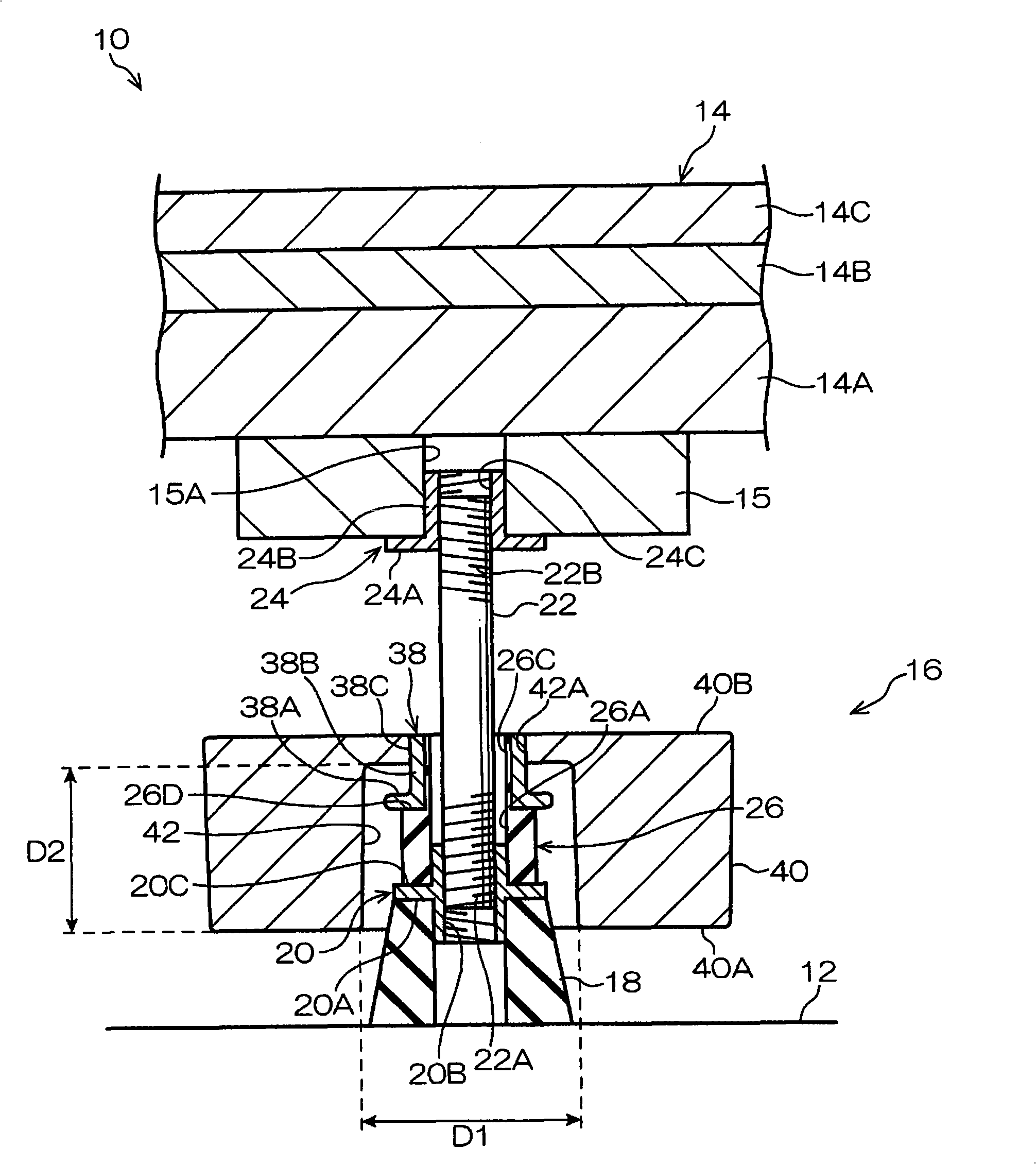

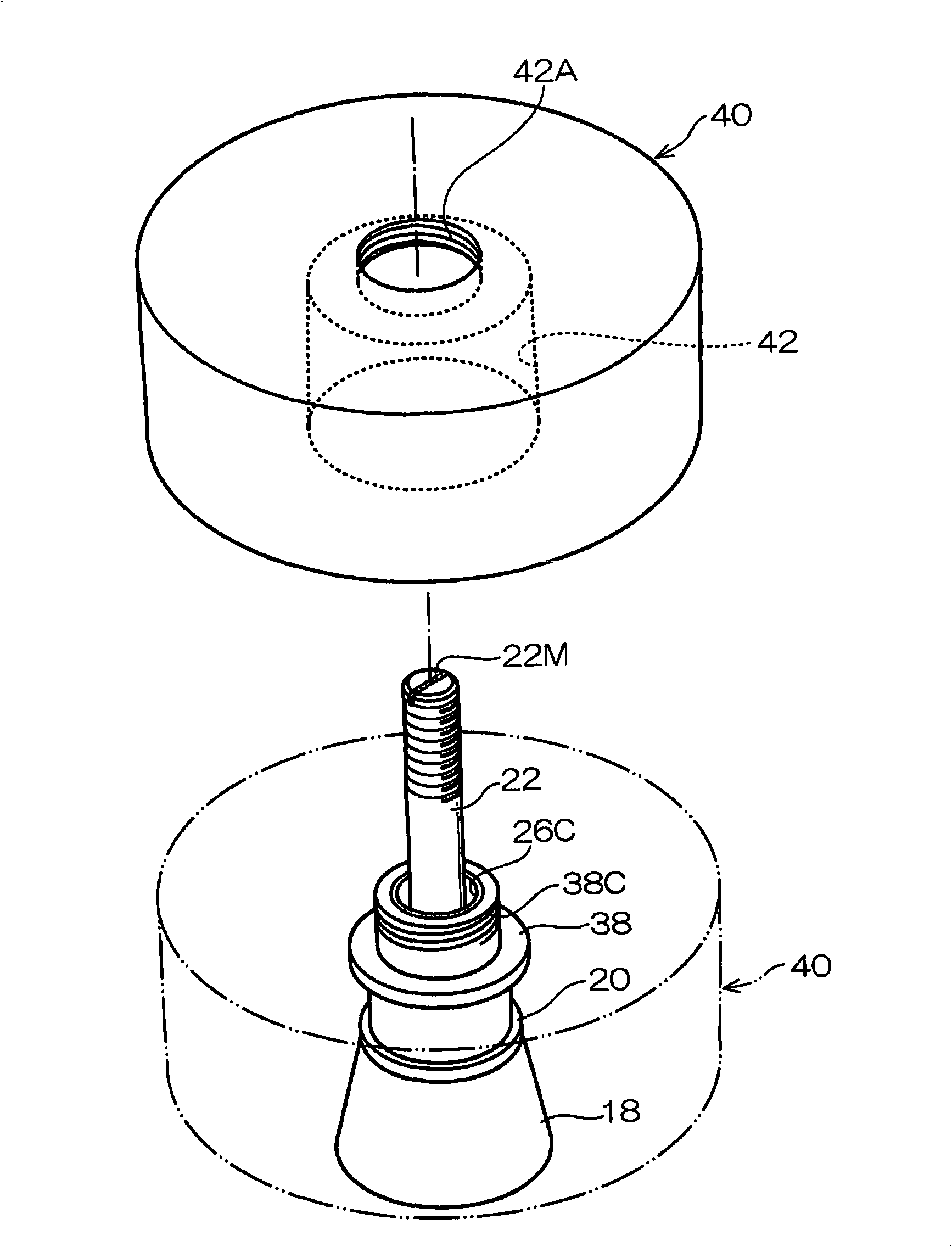

[0024] Hereinafter, embodiments of the floor support and the floor structure to which the floor support of the present invention are applied will be described with reference to the drawings. Arrow UP in the figure shows the upward direction of the floor structure.

[0025] The floor structure 10 shown in FIG. 1 is a structure mainly used for double-layer floors (dry soundproof double-layer floors) of multi-storey houses, and is used to reduce floor impact sounds (walking sounds, falling objects) generated on the upper floor and transmitted to the lower floor. sound, the sound of a child jumping, etc.).

[0026] Floor construction and structure of floor supports

[0027] As shown in FIG. 1 , the floor structure 10 is made in such a state that a plurality of floor support members 16 arranged at predetermined intervals are interposed between a concrete floor slab 12 as a floor main body and an upper floor member 14. The floor support 16 is interposed to form a space between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com