Bubbling automatic humidifier

A bubbling and humidifier technology, applied in air humidification systems, heating methods, lighting and heating equipment, etc., can solve problems such as high energy consumption, high noise, and impossibility of implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

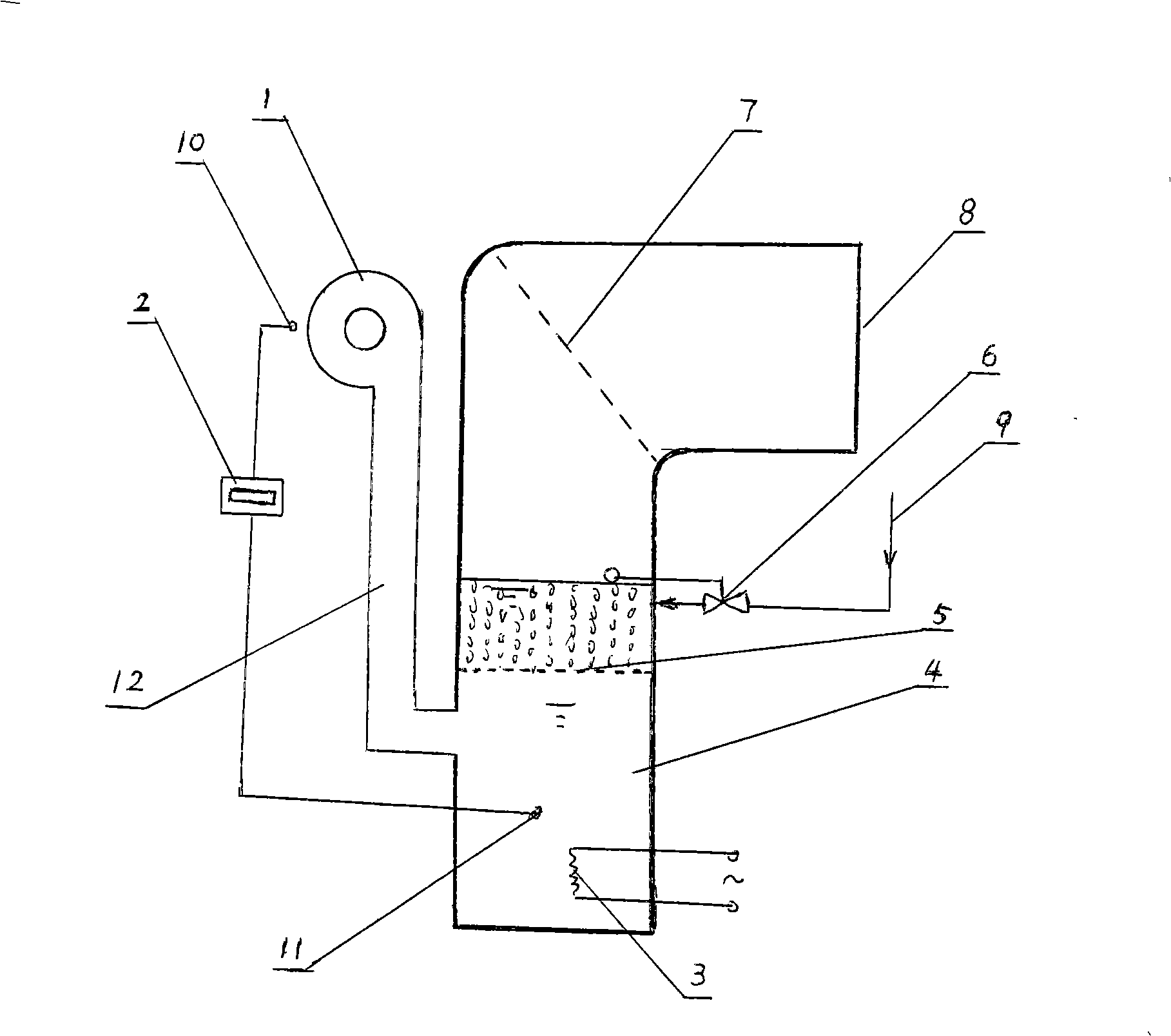

[0009] figure 1 It also shows a system diagram of a bubbling automatic humidifier that can humidify 20 kg of water per hour in a computer room. 250 through holes with a diameter of 2.5mm are evenly opened on a plastic plate with a thickness of 2mm. Such a porous plate 5 is placed horizontally in the bubbling chamber 4, and an appropriate amount is added to the bubbling chamber through the water supply pipe 9. The water level is controlled by the liquid level control valve 6 within the range of 40 mm above the upper part of the perforated plate 5. An electric heater 3 is installed in the pool below the perforated plate 5 to heat the pool in the bubbling chamber to about 60 ° C. When the air pump 1 When air is sent into the bottom of the bubbling chamber 4 through the air pipe 12, a large number of air bubbles will be formed in the hot water on the perforated plate, and float up in the water, and the air bubbles will quickly become saturated moist air. When the saturated humid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com