Solar cell and method for manufacturing the same

A solar cell and electrode technology, applied in the field of solar cells, can solve problems such as damage to the emitter, solar cell fill factor or energy conversion efficiency deterioration, etc., and achieve the effects of preventing shunt, excellent energy conversion efficiency, and filling factor improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

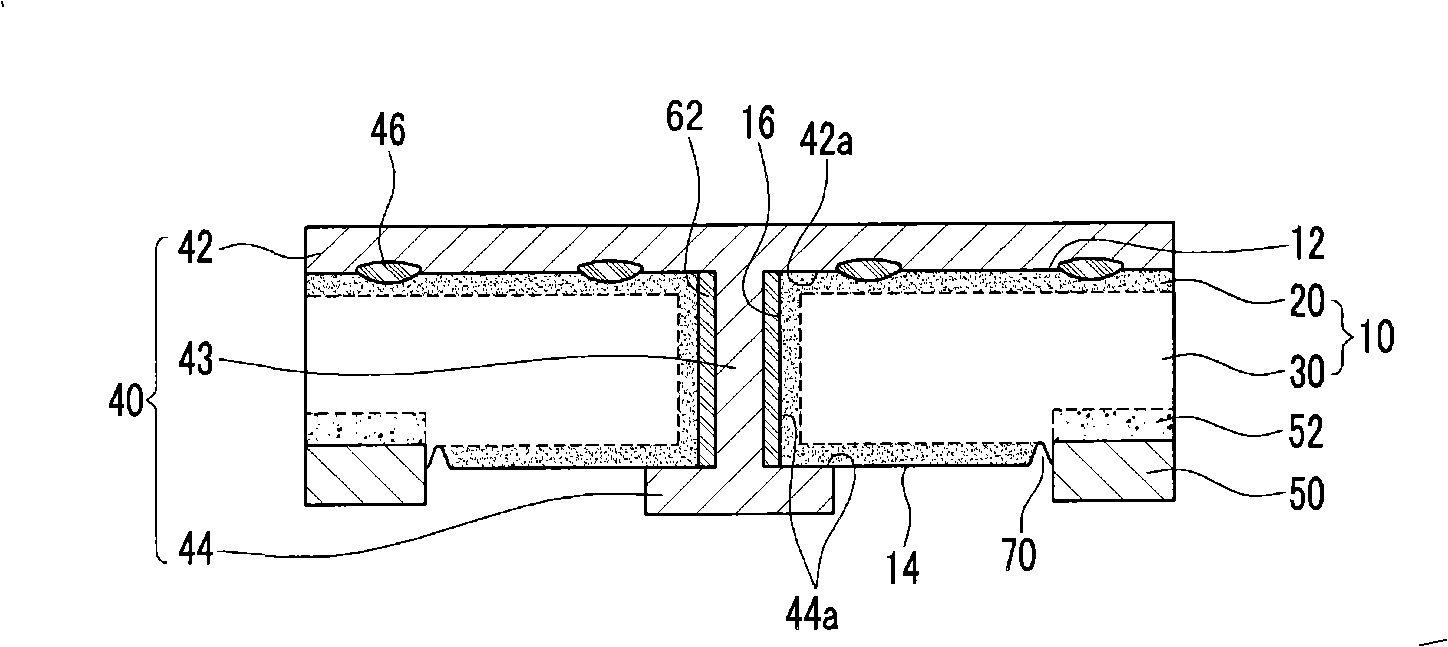

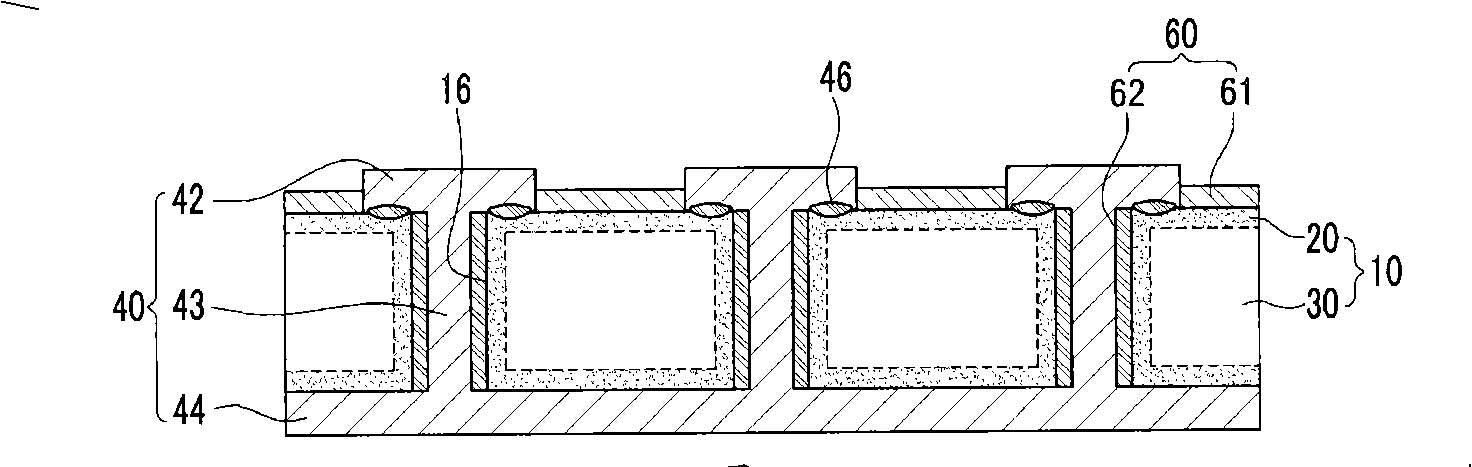

[0088] A p-type silicon semiconductor substrate having a thickness of 240 μm and including via holes with a diameter of 100 μm was formed. This semiconductor substrate has minute protrusions and recesses formed by texturing. Phosphorus oxychloride (POCl 3 ) was pyrolyzed in a diffusion furnace, a phosphosilicate glass (PSG) layer with a thickness of 0.5 μm was formed on the surface of this semiconductor substrate, and phosphorus in the PSG layer diffused into the semiconductor substrate to form an emitter portion. PSG was removed by dilute hydrofluoric acid (HF), and the unwanted portion of the phosphorus-diffused fraction was removed by potassium hydroxide (KOH) solution.

[0089] An antireflection layer composed of silicon nitride and having a thickness of 75 nm was formed on the front surface of the semiconductor substrate by plasma enhanced chemical vapor deposition.

[0090] A paste for forming the silver-containing first electrode portion is applied on the front surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com