Pointed brush thread made from recyclable organism-based raw material and preparation method

A technology of brush filament and pointed tip, which is applied in the field of pointed brush filament and its preparation, and can solve the problems of high equipment maintenance cost, harsh treatment conditions, and harmfulness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

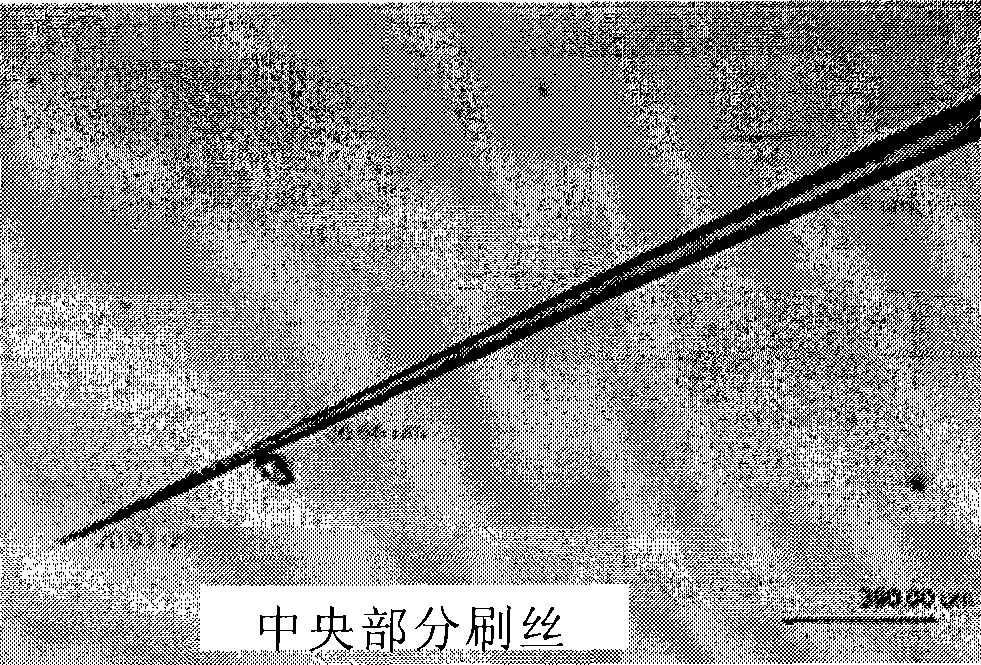

Image

Examples

preparation example Construction

[0027] One aspect of the present invention provides a method for preparing pointed brush filaments, the method comprising the following steps:

[0028] a) Provide brush wire;

[0029] b) adding treatment liquid in the pointed brush filament treatment tank;

[0030] c) immersing the brush filaments obtained in step a) in the treatment liquid for treatment, and applying an auxiliary device during the treatment, and the auxiliary device keeps the treatment liquid at a uniform concentration during the entire treatment process;

[0031] Wherein, the depth at which the brush filaments are immersed in the treatment liquid in step c) changes with time.

[0032] In the present invention, the brush filament monofilament is conventional in the art, and those skilled in the art can directly know which brush filaments can be used in the present invention. In a preferred example of the present invention, the brush filament monofilament can be made of polyester (such as polybutylene tereph...

Embodiment 1

[0057] 1. Will Salona After being melt-spun and heat-set, it is covered with a pre-packaged stretch film to form a tow.

[0058] 2. Cut the spun tow into 50 mm long silk cakes with a shredder.

[0059] 3. Add 40% NaOH aqueous solution into the pointed brush filament forming tank to form a treatment solution. Then the treatment solution was heated to 120° C., and the above-mentioned silk cake was immersed in the treatment solution to a depth of 10 mm, and mechanically stirred near the silk cake. After 10 minutes of treatment, the yarn cake was lifted 2 mm, so that the immersion depth of the brush filaments was 8 mm. After a further 10 minutes of treatment, the cake was lifted again by 2 mm. Repeat the above steps until the silk cake completely leaves the liquid level of the treatment liquid.

[0060] 4. Wash off the treatment liquid on the surface of the pointed brush wire with clean water, dehydrate the brush wire with a dehydrator, and dry the brush wire in the sun.

Embodiment 2

[0062] The difference from Example 1 is that step 3: add 40% NaOH aqueous solution in the pointed brush filament forming tank to form a pointed treatment solution, then heat the treatment solution to 120 ° C, and the silk cake is immersed in a depth of 4 mm, with mechanical stirring near the silk cake. The processing time was 40 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com