Continuous plate-expanding device of filter press and application thereof in filter press

A technology of plate puller and filter press, which is applied in the fields of attachments, installation structures and transmission mechanisms for continuous opening of filter plates. problem, to achieve the effect of fast speed, fast drawing speed and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical scheme of the present invention is described as an example below, to show those skilled in the art better understand the present invention:

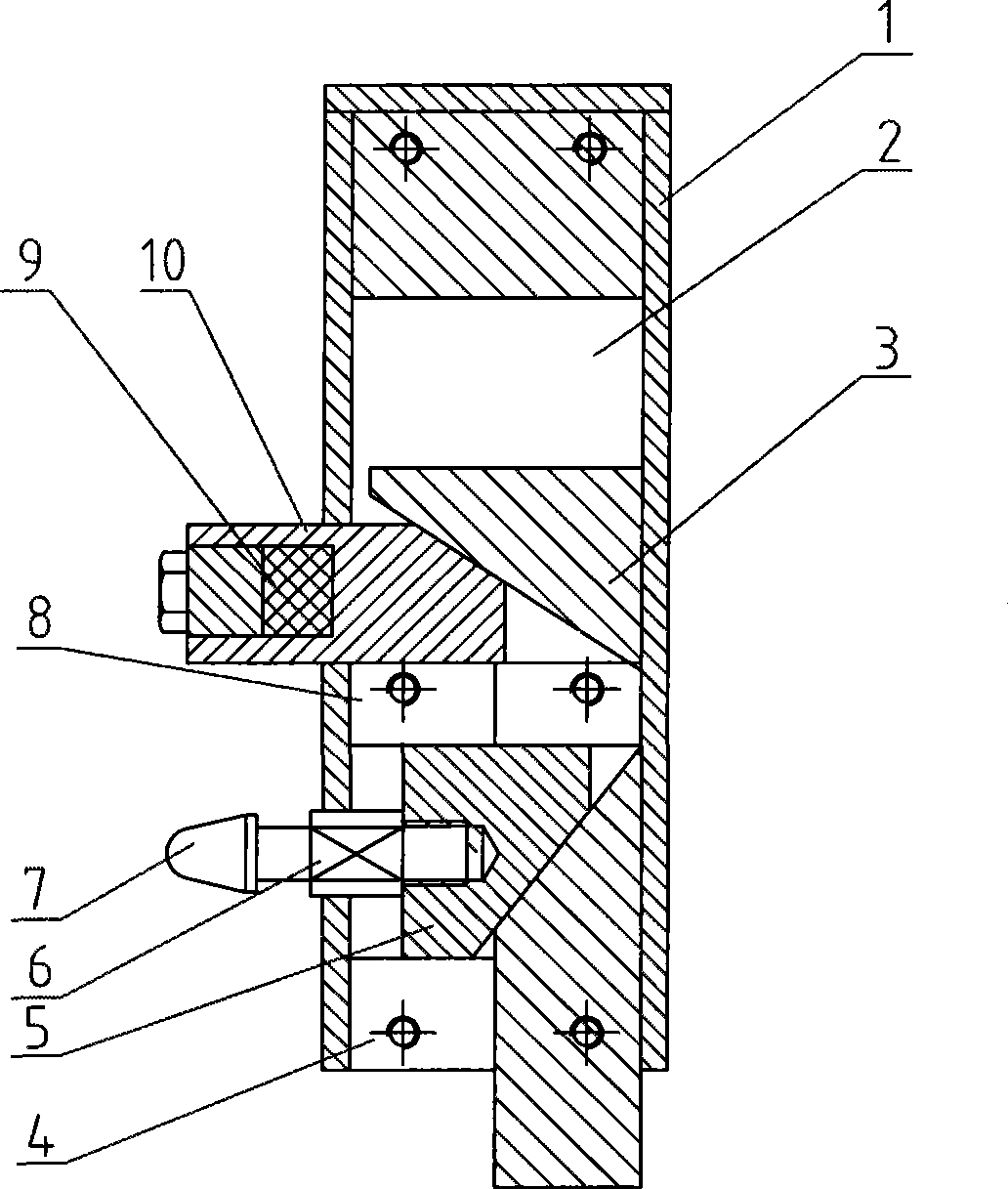

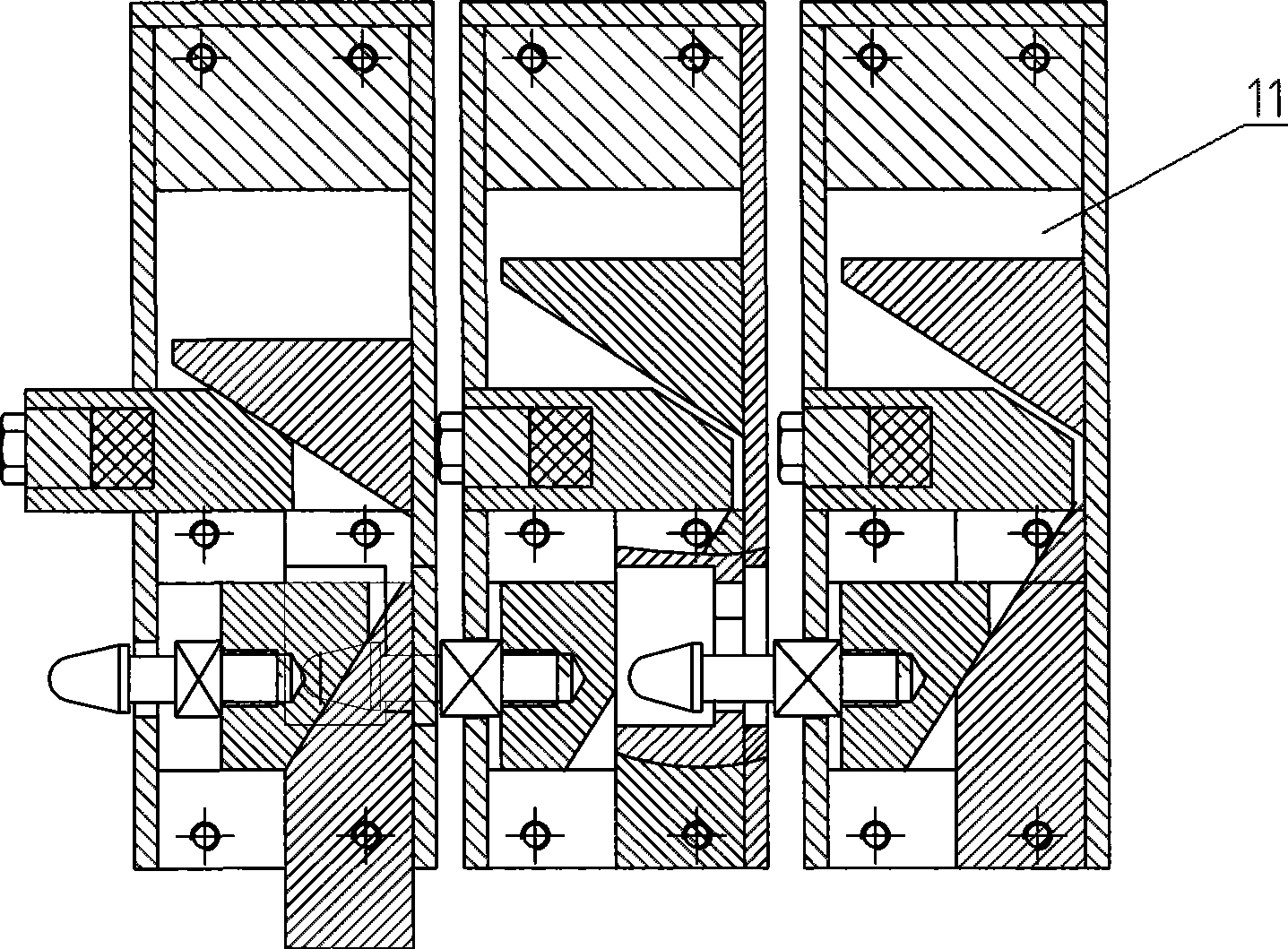

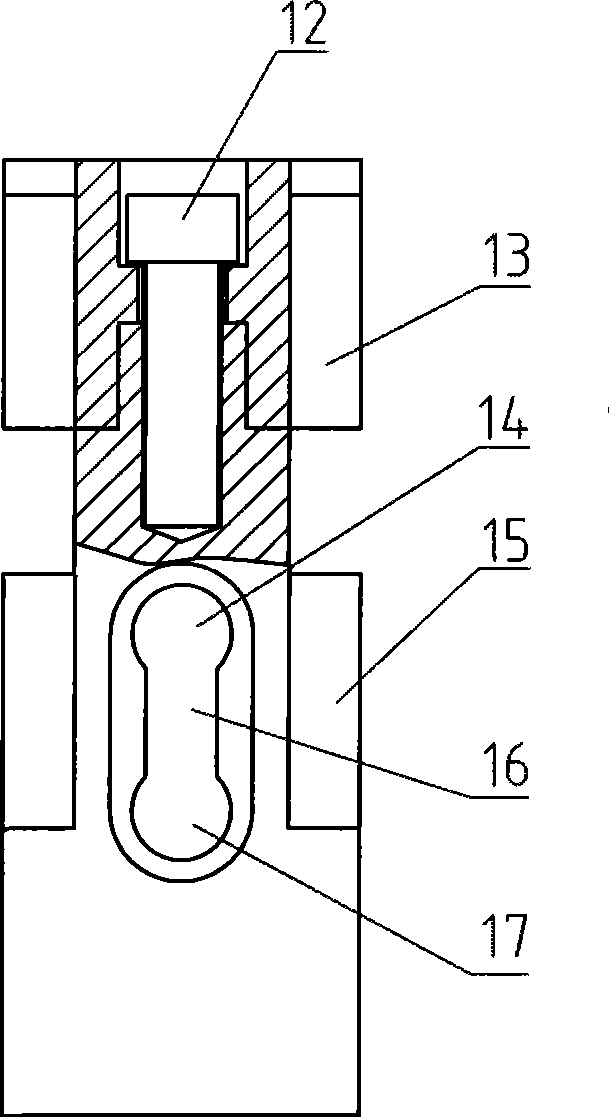

[0035] Refer to the attached Figures 1 to 4 , for said filter press continuous plate puller, it comprises:

[0036] The upper slider 10, as a driving component, its front end can withstand the impact to make it move horizontally, and the upper rear part is an inclined plane, and the matching member can move up and down through the cooperation of the inclined plane;

[0037] The lower slider 5 is used for locking between the filter plates. The front part is a lock column 6, and the rear lower part is a load-bearing inclined surface, which can make it move horizontally depending on the bearing force. The front end of the lock column has a bottom surface whose diameter is larger than that of the lock column body. Diameter of tapered lock head 7;

[0038] The vertical slider 3 cooperates with the slopes of the above-m...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap