Off-line planning method for cutting feed rate of five-shaft numerical control side milling machining

A feed rate, off-line technology, applied in metal processing equipment, milling machine equipment, manufacturing tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solution of the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. The following examples are not intended to limit the present invention.

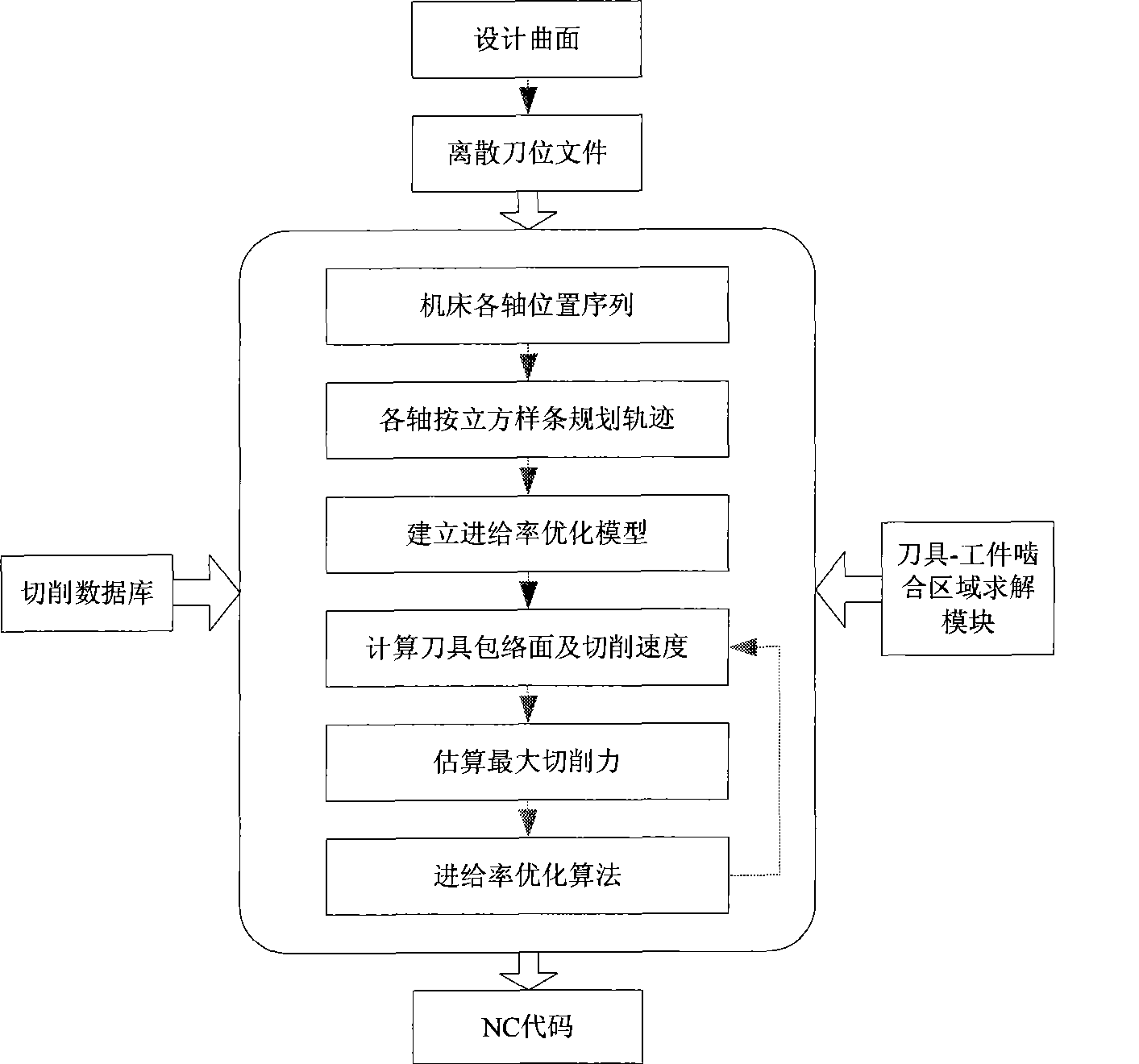

[0032] The process flow of the five-axis CNC side milling feed rate off-line planning method proposed by the present invention is as follows figure 1 shown.

[0033] Firstly, the discrete tool position file corresponding to the design surface is reversed by machine kinematics to obtain the discrete position sequence of each axis of the machine tool; each axis follows the cubic spline polynomial interpolation format, and the adjacent position points of each axis are initially set at equal time intervals The running time between each axis; the establishment takes the running time sequence between the adjacent position points of each axis as the design variable, takes the minimum sum of the running time sequence between the adjacent position points ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com