Composite modifying agent and low-strength concrete prepared thereby

A composite modifier, low-strength technology, applied in the field of building materials, can solve the problems of high price and not easy to obtain, and achieve the effect of ensuring durability, significant economy, and improving resistance to environmental water erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

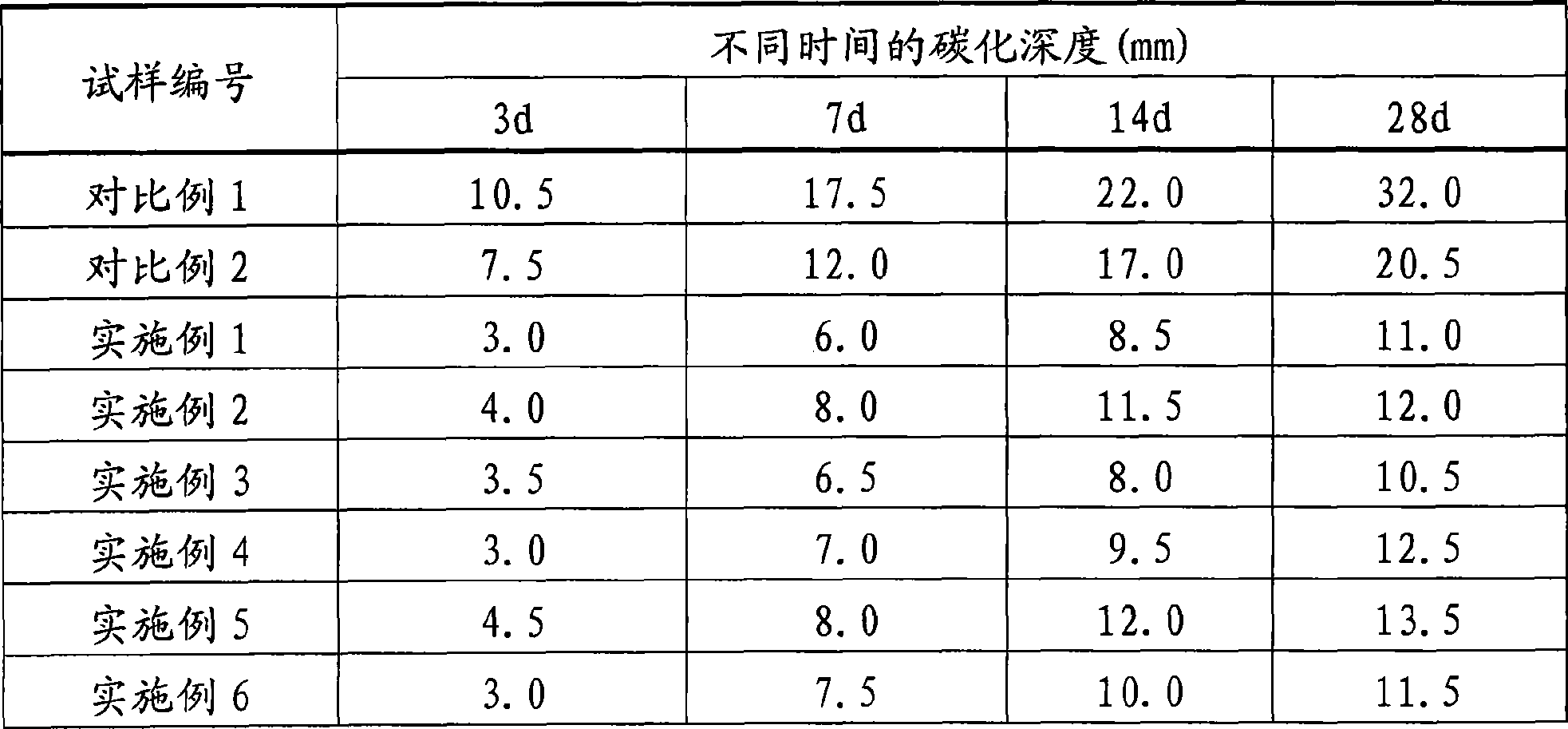

Embodiment 1

[0030] The low-strength concrete of this embodiment is composed of the following components: 15.8kg of ordinary Portland cement, 15.8kg of composite modifier, 14.2kg of water, 75.0kg of sand, and 105.0kg of gravel;

[0031] The composite modifier is composed of the following components: 14.35kg II low-calcium fly ash, 0.01kg SJ-2 air-entraining agent, 0.72kg naphthalenesulfonate solid powder water reducer, 0.72kg sodium sulfate. The compounding ratio of the composite modifier is: 100 parts of low-calcium fly ash of class II, 0.1 part of SJ-2 type air-entraining agent, 5 parts of naphthalene sulfonate solid powder water reducer, and 5 parts of sodium sulfate.

Embodiment 2

[0033] The low-strength concrete of the present embodiment is made up of following components:

[0034] Ordinary Portland cement 13.0kg, compound modifier 19.5kg, water 13.6kg, sand 73.0kg, gravel 107.0kg;

[0035] The composition of the composite modifier is: 17.71kg II grade low calcium fly ash, 0.02kg SJ-2 air-entraining agent, 0.885kg naphthalene sulfonate solid powder water reducer, 0.885kg sodium sulfate. The compounding ratio of the composite modifier is: 100 parts of high-grade low-calcium fly ash, 0.1 part of SJ-2 type air-entraining agent, 5 parts of naphthalene sulfonate solid powder water reducer, and 5 parts of sodium sulfate.

Embodiment 3

[0037] The low-strength concrete of the present embodiment is made up of following components:

[0038] Ordinary Portland cement 15.3kg, compound modifier 15.3kg, water 13.7kg, sand 73.5kg, gravel 109.0kg;

[0039] The composition of the composite modifier is as follows: 14.15kg II grade low-calcium fly ash, 0.02kg SJ-2 air-entraining agent, 0.71kg naphthalene sulfonate solid powder water reducer, 0.42kg sodium borate. The compounding ratio of the composite modifier is: 100 parts of high-grade low-calcium fly ash, 0.12 parts of SJ-2 type air-entraining agent, 5 parts of naphthalene sulfonate solid powder water reducer, and 3 parts of sodium borate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| mass | aaaaa | aaaaa |

| mass | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap