Model updating method for on-line boiler combustion optimization

A combustion optimization and model update technology, applied in the direction of combustion control, comprehensive factory control, comprehensive factory control, etc., can solve the problems of not being able to use the learning results, shorten the calculation workload and time of model updating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] A model update method for boiler online combustion optimization, the specific steps are:

[0036] (1) Establish the prediction error database of the existing model. According to the specific boiler combustion conditions and the requirements for the prediction accuracy of the model, set the allowable prediction error limit δ of the model, and judge the error between the model prediction value and the actual operating value and the size of the allowable prediction error limit δ when collecting data, if The prediction error is greater than δ, ie |V c -V s |>δ, where V c is the predicted value of the model, V s For the actual operation data, the overrun data will be stored in the prediction error database for model update.

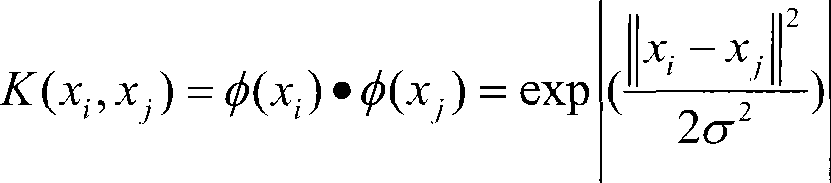

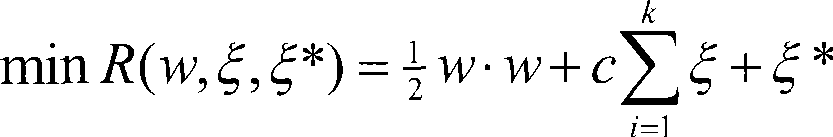

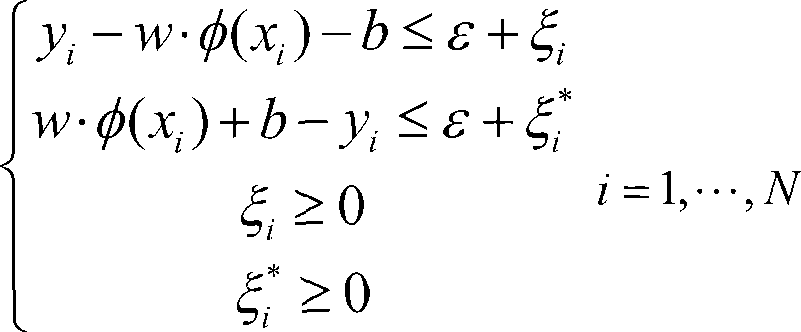

[0037] (2) Establish a new model. When the original model needs to be updated, the data in the prediction error database is used as the training sample, and the sample can be expressed as where x i Represents the i-th group of boiler operating p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com