Sound absorbing structure and vehicle component having sound absorbing properties

A technology for sound-absorbing and vibrating components, which is applied to vehicle components, sound-generating devices, transportation and packaging, and can solve problems such as the impossibility of achieving high sound absorption rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0075] (A) Sound-absorbing structure

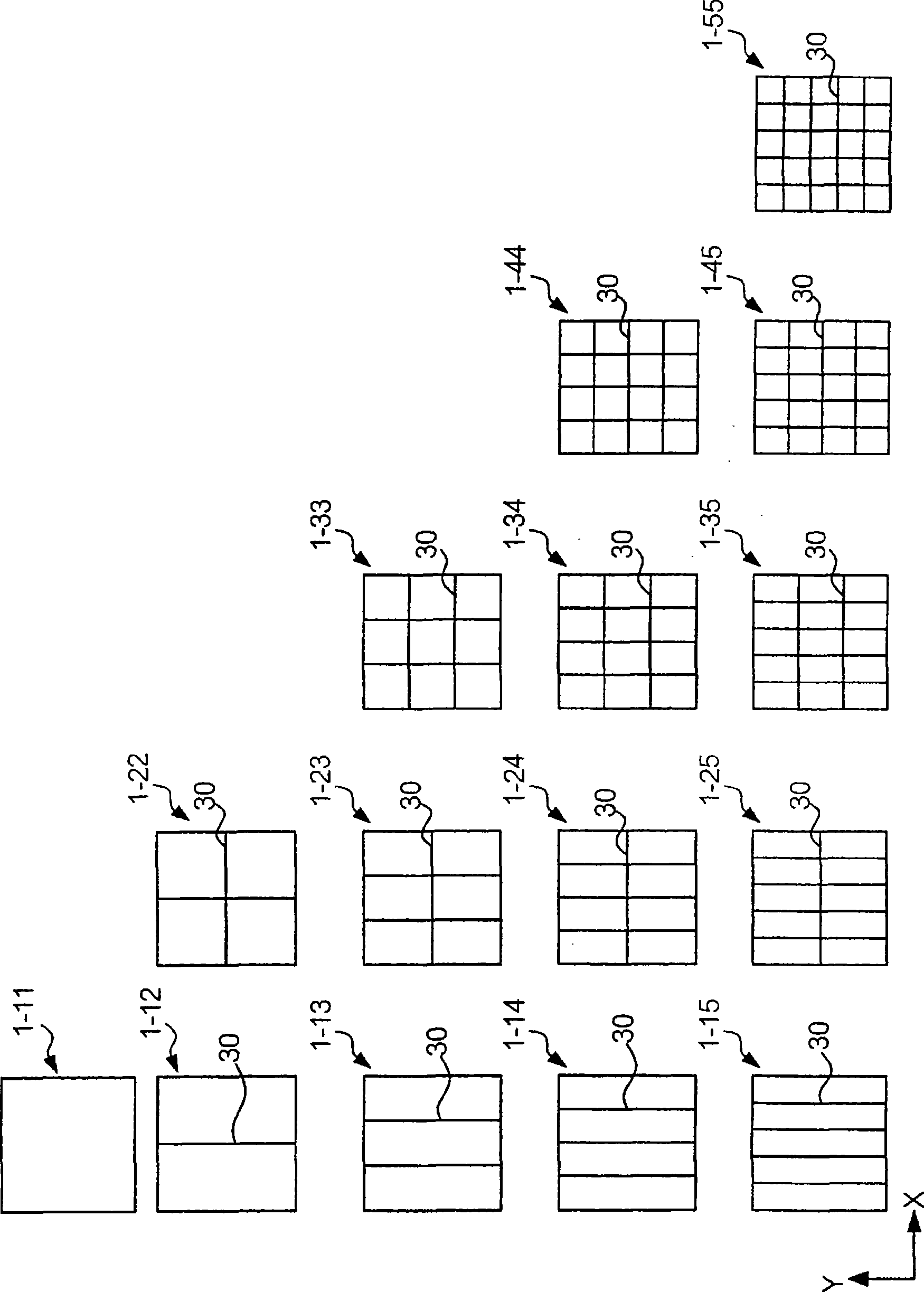

[0076] will refer to Figure 1 to Figure 6 A sound absorbing structure according to a first embodiment of the present invention will be described.

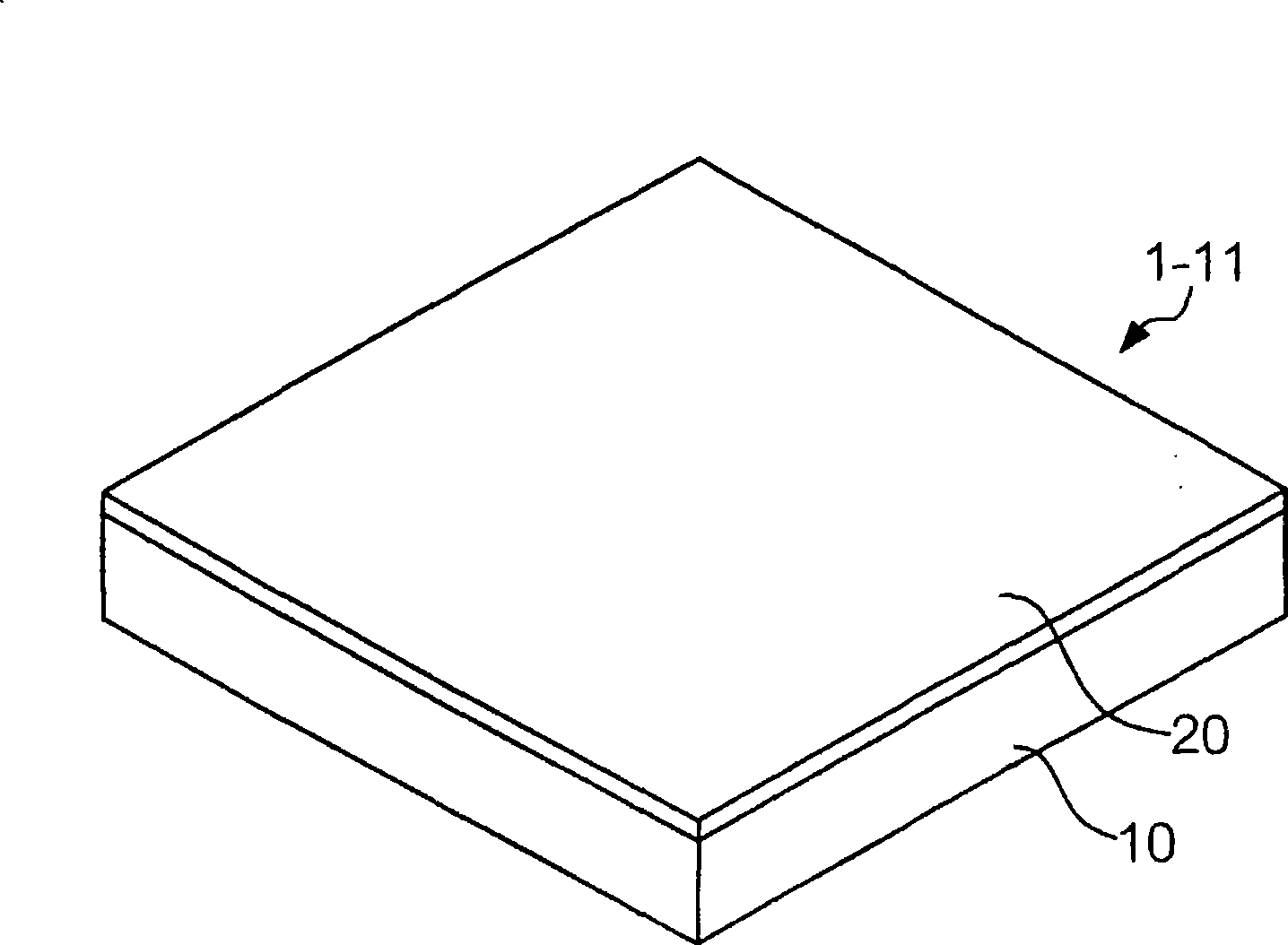

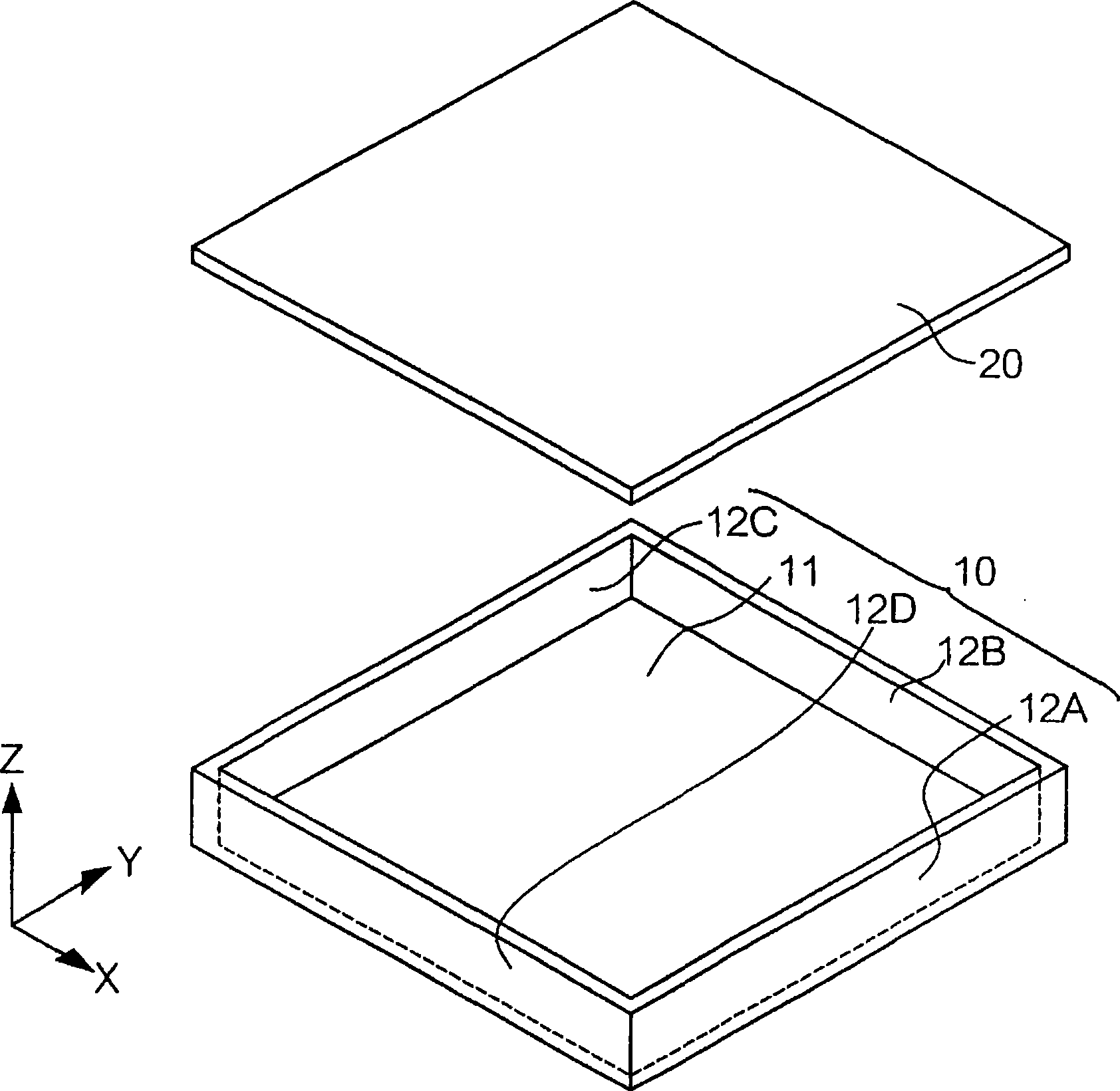

[0077] figure 1 is the external view of the sound-absorbing structure 1-11; figure 2 is an exploded perspective view of the essential parts of the sound-absorbing structure 1-11. In order to explain the constitution of this embodiment in an easy-to-understand manner, the size of the sound absorbing structure 1-11 does not exactly correspond to the actual size.

[0078] The sound absorbing structure 1 - 11 is composed of a case 10 and a vibrating member 20 . A casing 10 made of synthetic resin is molded into a hollow square cylinder with one end open and the other closed, wherein the casing is composed of a bottom 11 forming a bottom of the casing and side walls 12A to 12D.

[0079] The vibrating member 20 is a square member produced by molding synthetic resin having elasticity into a pl...

no. 3 example

[0174] will refer to Figure 13 and 14 A third embodiment of the present invention is described. exist Figure 13 in, with Figure 9 and 10 Component parts that are the same as those shown in are designated with the same reference numerals.

[0175] Figure 13 is a perspective view showing the appearance of a sedan 100 employing a sound absorber SA_2 according to a third embodiment of the present invention. A hood 101, four doors 102, and a trunk door 103 are each attached in an open / closed manner to a chassis 110 corresponding to a base of the vehicle structure. like Figure 10 A chassis 110 of the vehicle 100 is formed as shown. Compared to the second embodiment in which the sound absorber SA_1 is attached to the back pocket tray 130 , the third embodiment is designed to attach the sound absorber SA_2 to the roof 240 . Top 240 consists of top outer plate (corresponding to Figure 10 The top 115 in the middle) and the top inner plate 230 constitute.

[0176] The th...

no. 4 example

[0180] The fourth embodiment is characterized by attaching the box-shaped sound absorber SA_3 to the sun visor 330 of the vehicle 100 . Figure 15 is a developed view of the sun visor 330 attached to the upper part of the roof 115 of the vehicle 100, Figure 16 is along Figure 15 A cross-sectional view taken along line A-A in .

[0181] The sun visor 330 is composed of a plate-shaped light insulation part 340 and an L-shaped support rod 350 for rotatably supporting the light insulation part 340 .

[0182] The light-shielding part 340 is composed of a core material 341 formed of ABC resin (or engineering plastics) and a surface material 360 formed of a non-woven fabric having sound transmission properties. The core material 341 is covered with the surface material 360 so that the respective sides of the surface material 360 are bonded together to cover the surface and the back of the core material 341 .

[0183] A bracket 351 for attaching the sun visor 330 to the roof 115 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com