Electric lever type leakage preventing socket

A leakage protection and socket technology, applied in multiple unbalanced current/voltage switches, circuits, electrical components, etc., can solve the problems of slow breaking speed, difficult tripping, and inability to protect personal safety, etc., to improve the breaking speed. , the effect of protecting safety, high sensitivity and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Referring to the accompanying drawings, the present invention will now be described in detail.

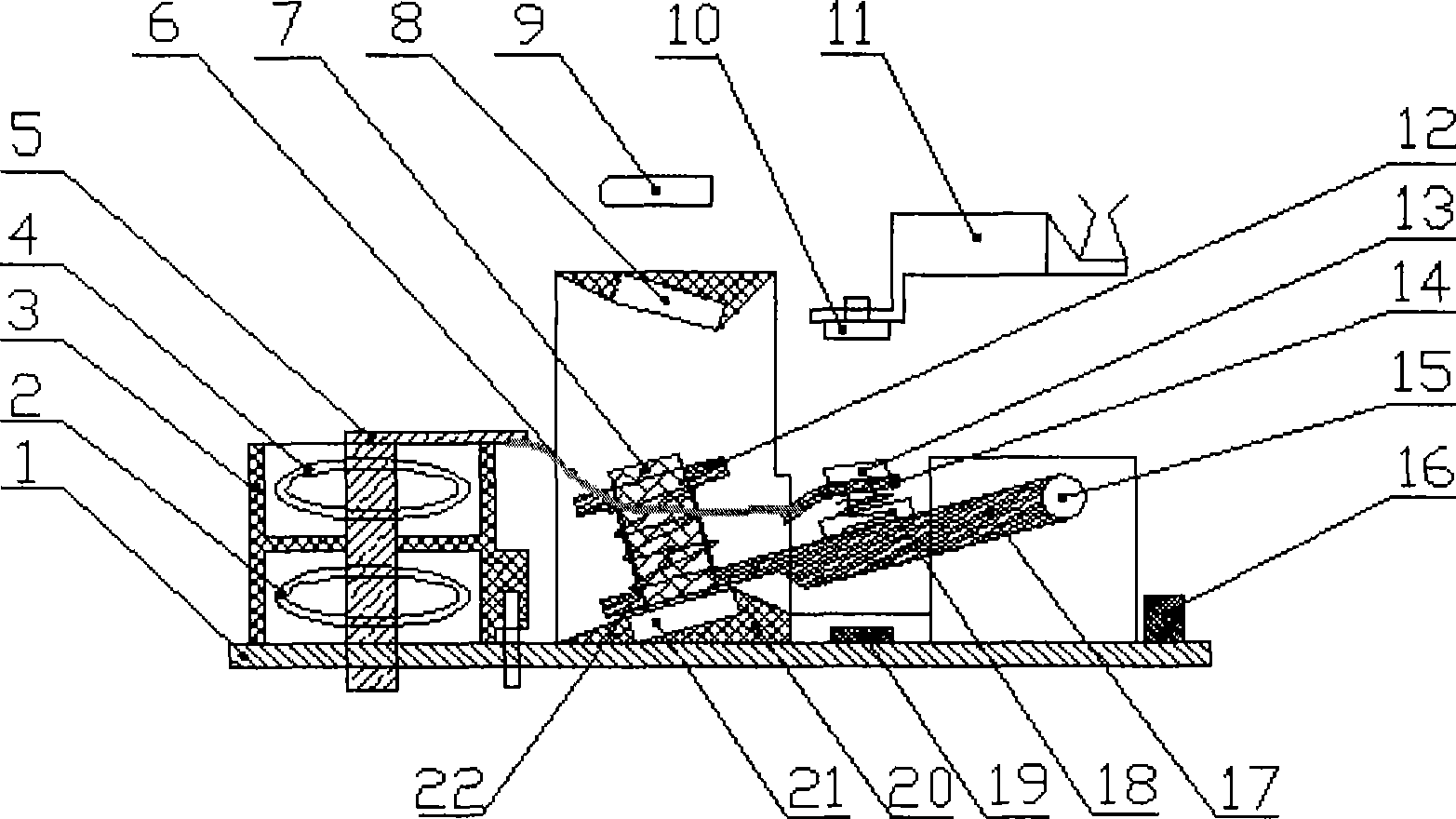

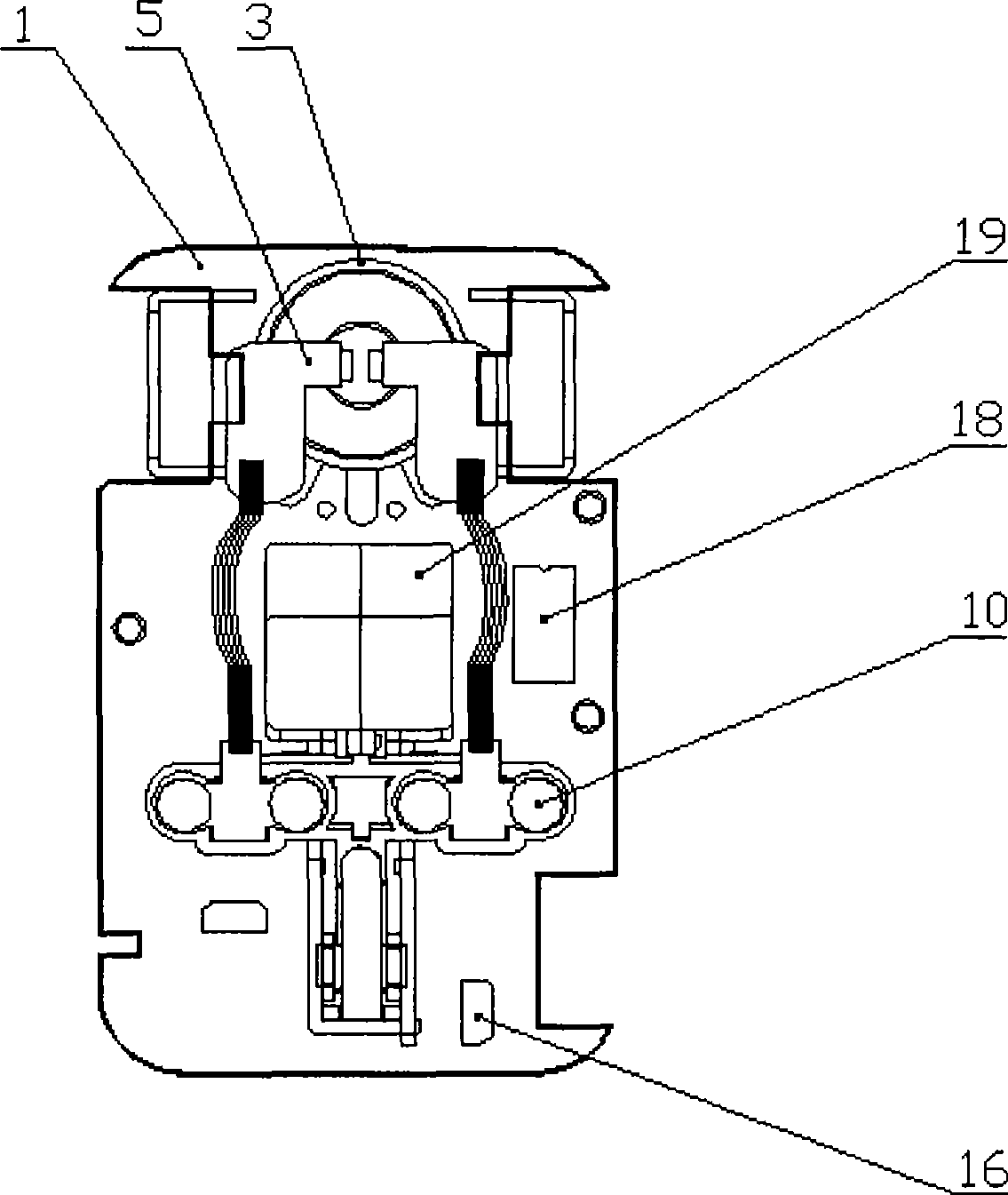

[0013] refer to figure 1 , which shows a schematic structural view of the leakage protection socket according to the present invention. The earth leakage protection socket comprises a circuit board 1 on which a transformer assembly 3, a tripping coil assembly 20, a control circuit (including a thyristor 16, a control chip 19 and other required electronic components (not shown)) are mainly installed. . The transformer assembly includes zero sequence transformer 4 (L1) and neutral transformer 2 (L2). Two conductive strips 5 of the live line L of the power supply and the neutral line N pass through the middle of the transformer assembly 3 . Copper special flexible wire 6 is spot-welded on the conductive sheet 5, and is connected with the movable contact sheet 14, and the movable contact sheet 14 is riveted with a movable contact 13, and is equipped with a contact spring 18. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com