External rotor type motor with multiple rotors and multiple stators

A multi-rotor, multi-stator technology, applied in the direction of electronic commutation motor control, electrical components, electromechanical devices, etc., can solve problems such as uncompact structure and torque imbalance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] specific implementation plan

[0019] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings

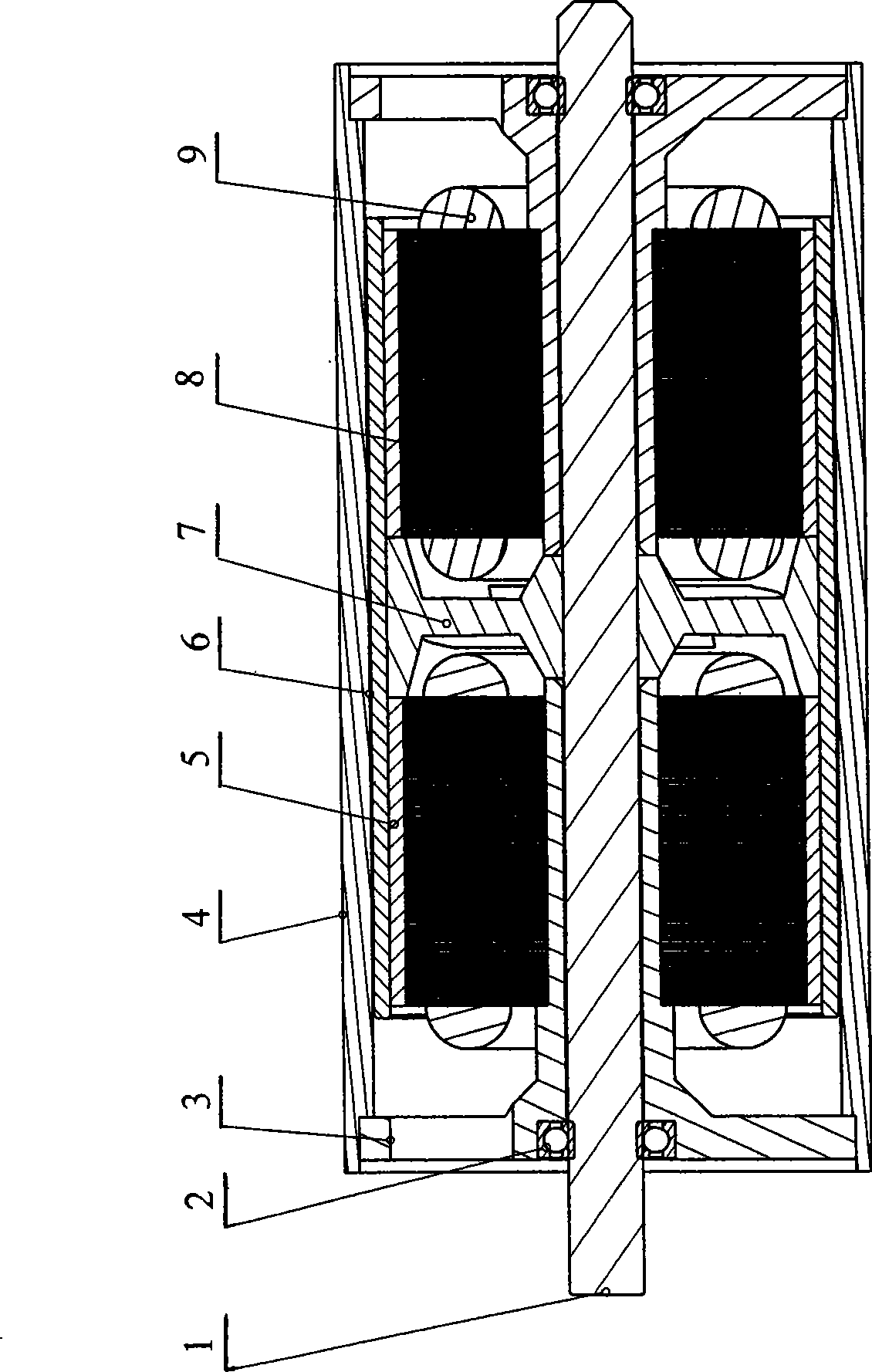

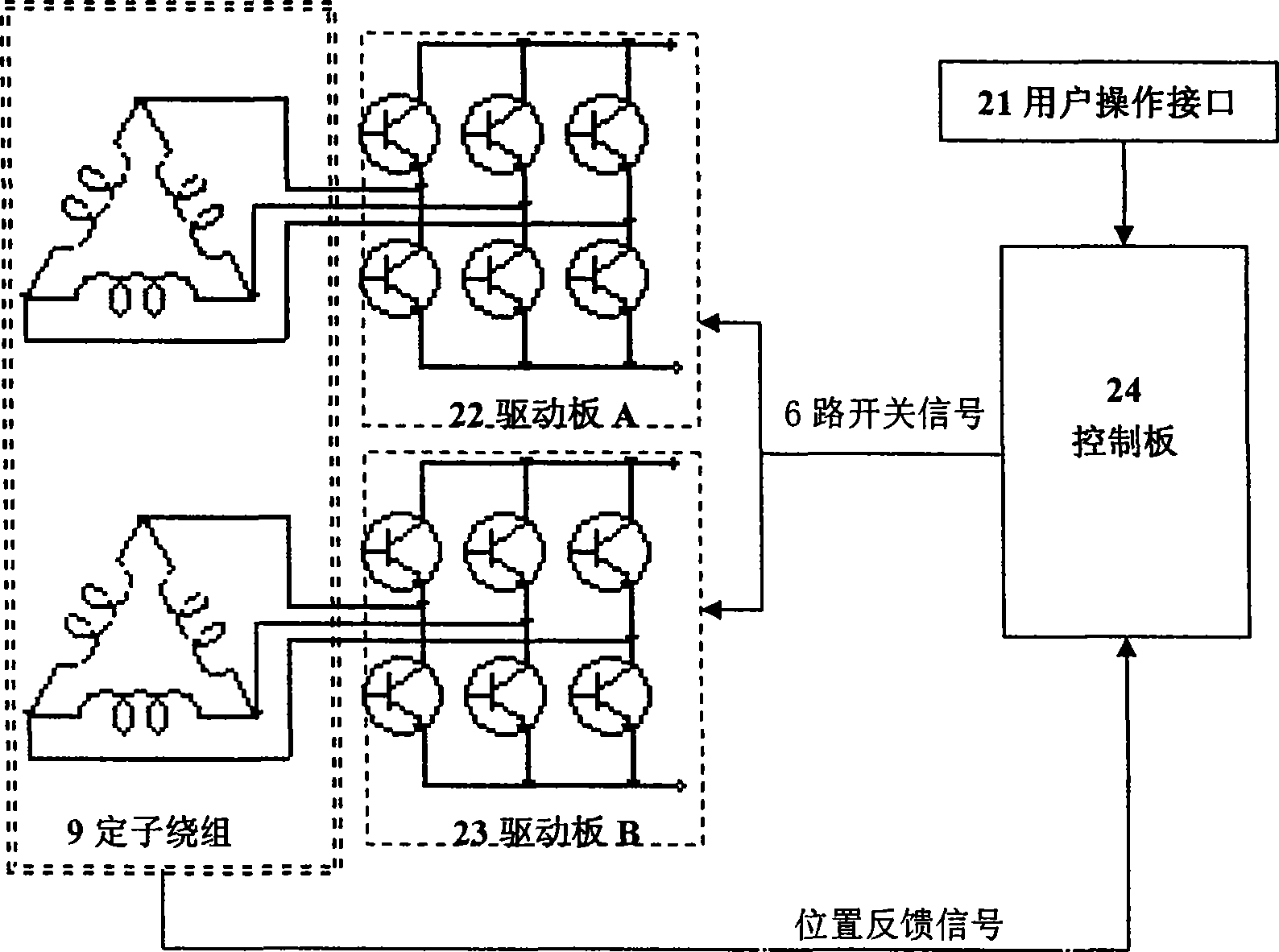

[0020] Such as Figure 1~2 As shown in the figure: 1—Rotating shaft, 2—Bearing, 3—End cover, 4—Shell, 5—Magnet, 6—Rotor shell, 7—Support frame, 8—Fixed punching piece, 9—Stator winding, 21—user operation interface, 22—drive board A, 23—drive board B, 24—control board.

[0021] An embodiment of an external rotor type multi-rotor and multi-stator motor takes two sets of rotors and two sets of stators as an example: a support frame 7 is tightly pressed into a rotor shell 6 and the rotor shell is divided into two cavities. The supporting frame is a disc-shaped member, and its connection with the rotor 6 and the rotating shaft 1 extends from the central plate-shaped structure to both sides to form a symmetrical structure, so as to increase the contact surface and improve stability. Each cavity separated by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com