Automatic industrial robot based on single flexible track

An industrial robot and flexible track technology, applied in manipulators, manufacturing tools, etc., can solve the problems of fluctuations in industrial robots, inability to meet accuracy requirements, and inability to ensure parallel orbits, to improve flexibility and universality, and ensure smooth operation. , to achieve the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings. First of all, it is stated that the orientation mentioned in this application, such as the positioning reference of the front and side, is based on the direction that the automatic industrial robot faces and runs forward along the flexible track, and the positioning of all modules is based on this.

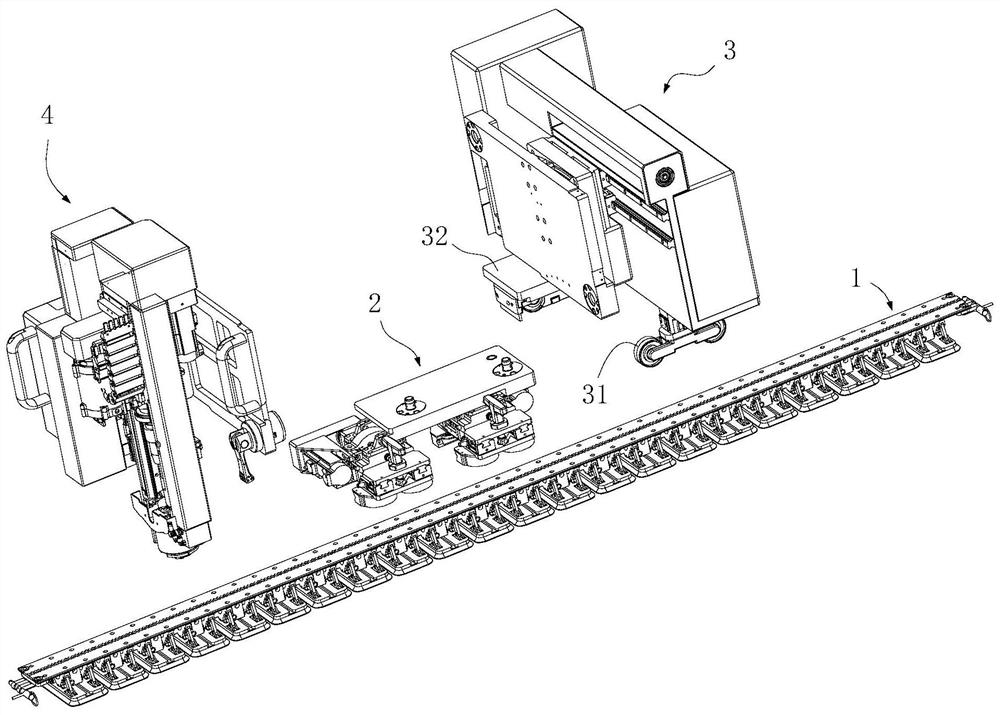

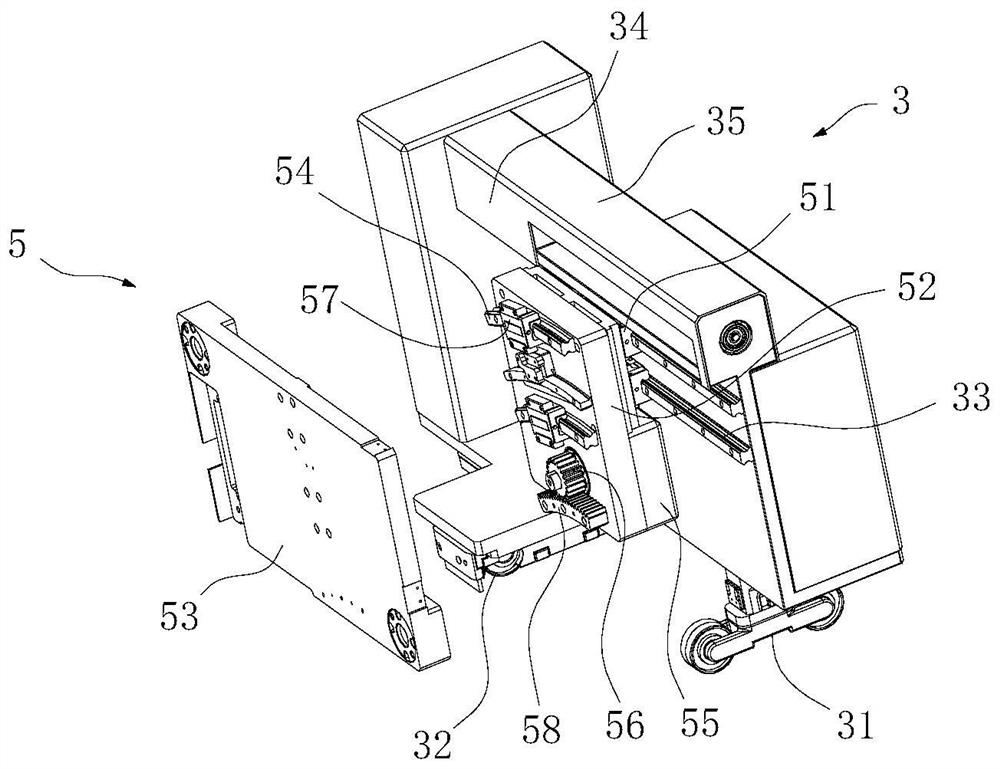

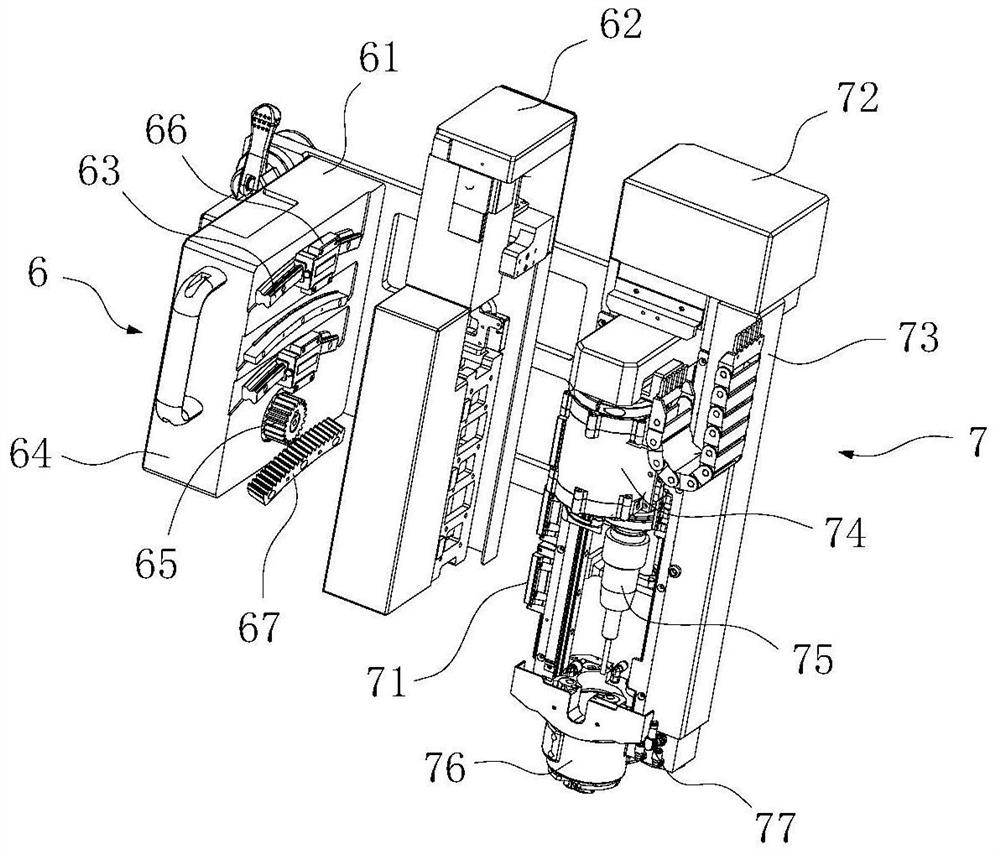

[0022] Such as Figure 1-3 As shown, the automatic industrial robot based on a single flexible track of the present invention includes a flexible track 1, an X-axis module 2 that can run along the flexible track 1, a Y-axis module 3 positioned on the X-axis module 2, and a Y-axis module 3 installed on the X-axis module 2. On the actuator module 4, the left and right sides of the Y-axis module 3 exceed the flexible track 1, and the left and right sides are respectively provided with fixed support wheels 31 and floating support wheels 32, and the fixed support wheels 31 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com