Production method for novel piezoelectric thin-film resonator

A piezoelectric thin film and resonator technology, applied in the field of preparation of new piezoelectric thin film resonators, can solve the problems of complex preparation process and high manufacturing cost, and achieve the effects of simplified process, strong mechanical properties and stable resonance area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0020] Embodiment: prepare piezoelectric thin film resonator, its steps are:

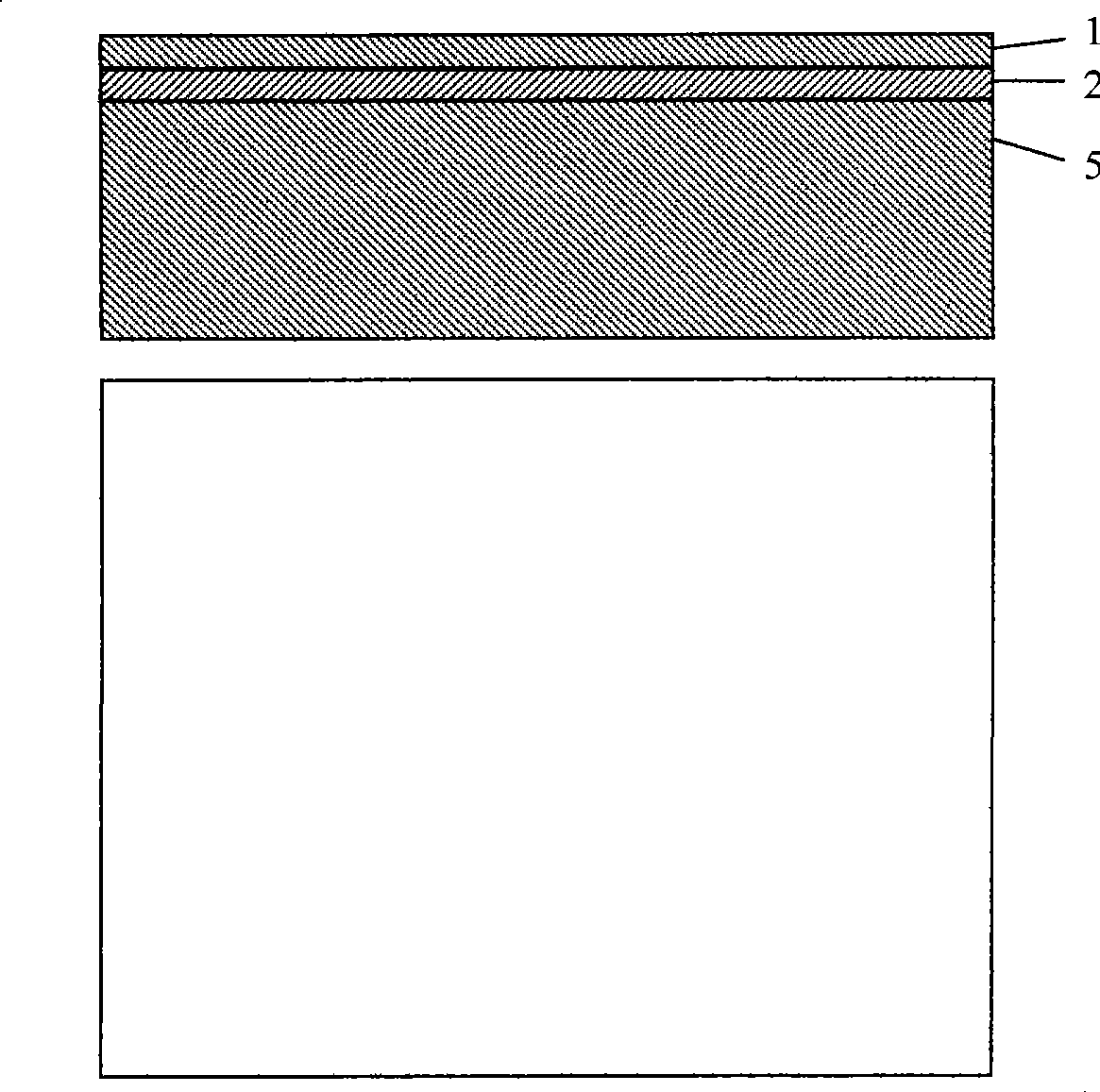

[0021] (1), substrate cleaning: take SOI wafer as substrate (see figure 1 ), put it into a mixture of hydrogen peroxide, ammonia and deionized water (the ratio is 1:3:10) and boil for 3 minutes, then put it into a mixture of hydrogen peroxide, hydrochloric acid and deionized water (the ratio is 2:3:10) for 3 minutes, soaked in a mixture of hydrofluoric acid and deionized water (1:10) for a few seconds, and finally dried with nitrogen.

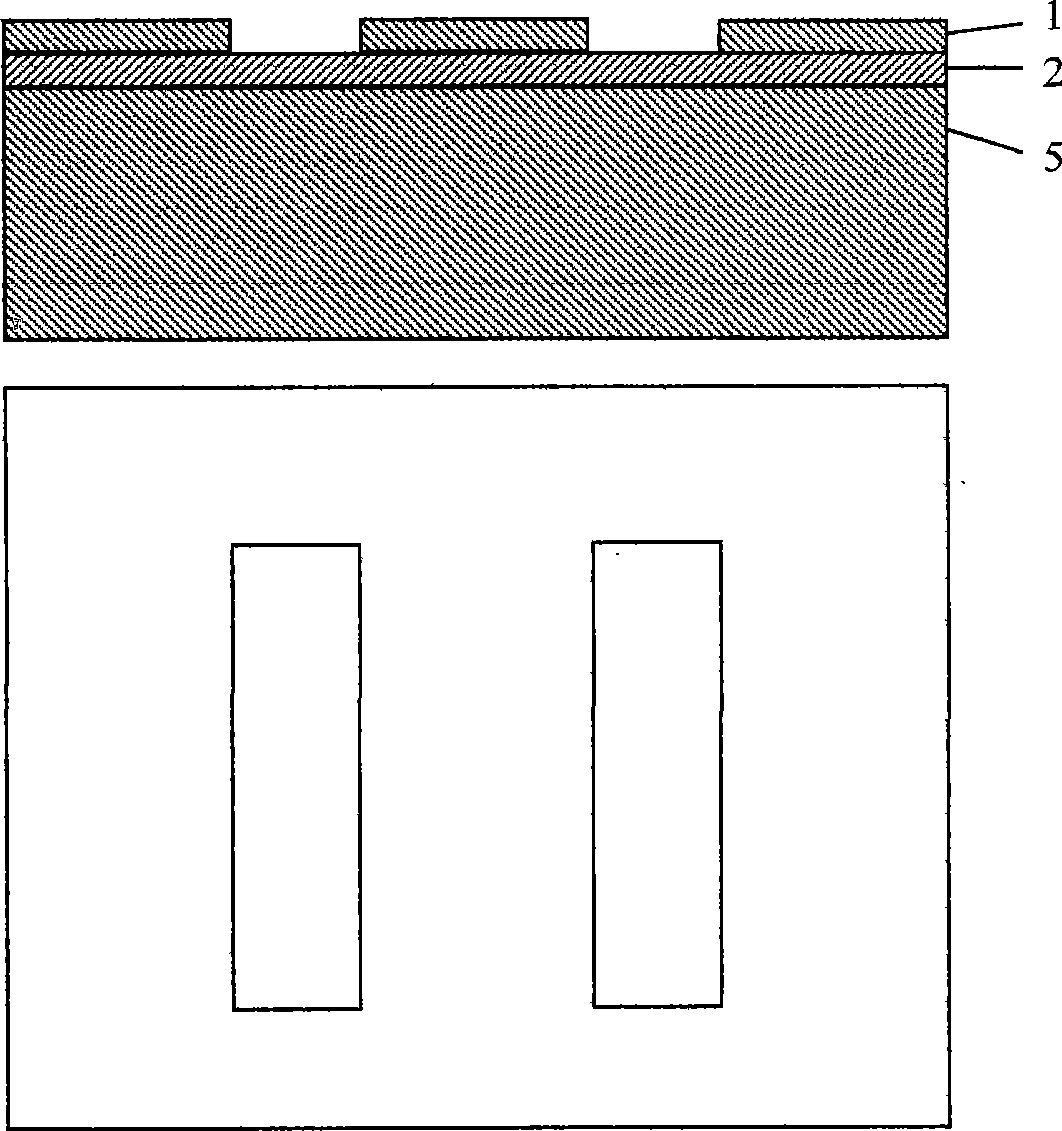

[0022] (2), photolithography of the top layer silicon etching groove: adopt the method of coating photoresist, after exposure, development, and finally corrode the unprotected part of photoresist, the window of top layer silicon is etched and formed (see figure 2 ). The etchant used is nitric acid (HNO 3 ), hydrofluoric acid (HF), acetic acid (CH 3 COOH) and deionized water in several proportions mixed solution.

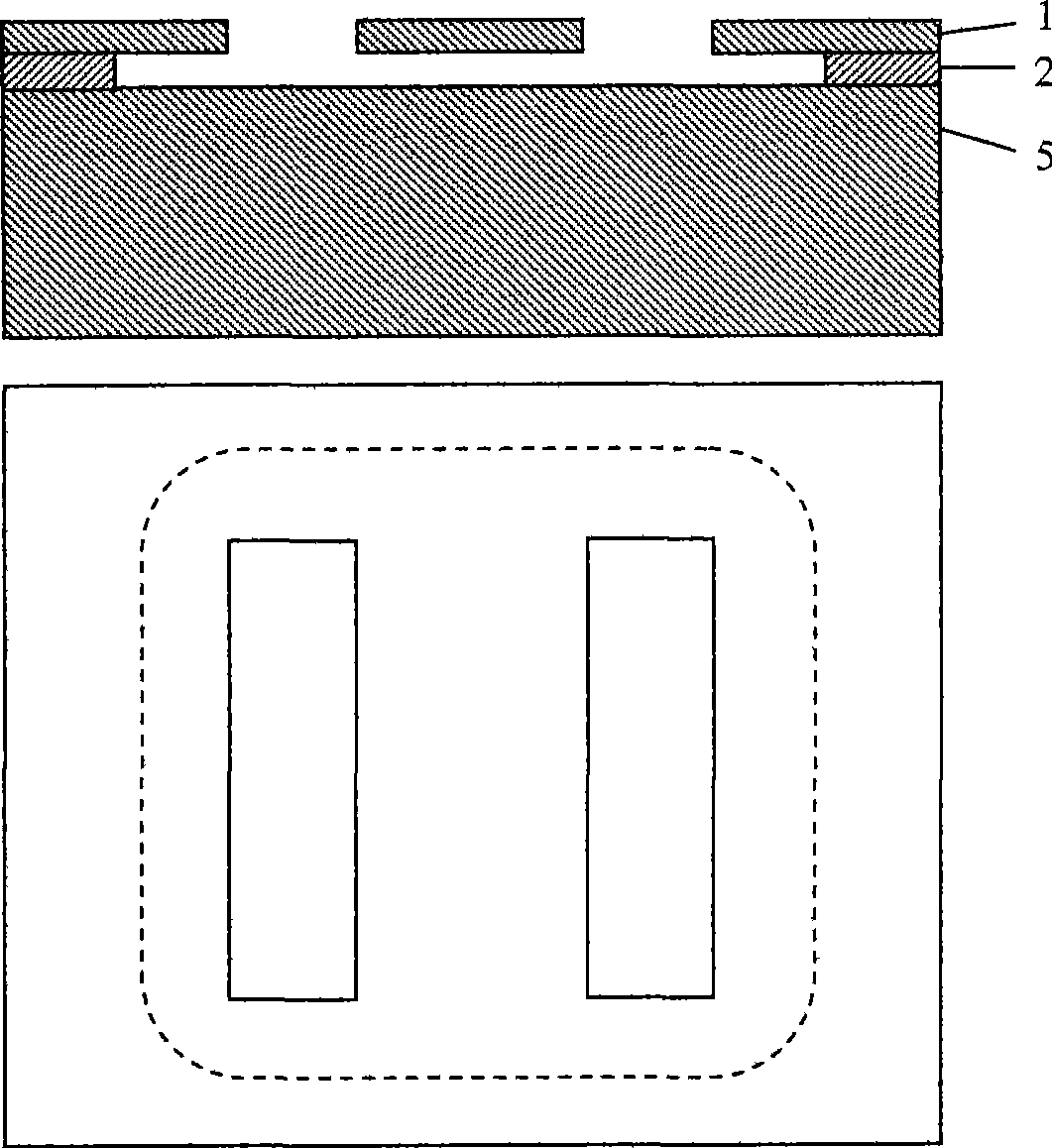

[0023] (3), SOI intermediate insulating layer S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap