Pneumatic tire

A technology of pneumatic tires and tires, which is applied to tire parts, tire tread/tread pattern, transportation and packaging, etc., to achieve the effects of increasing ground contact area, improving snow removal performance, and improving driving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

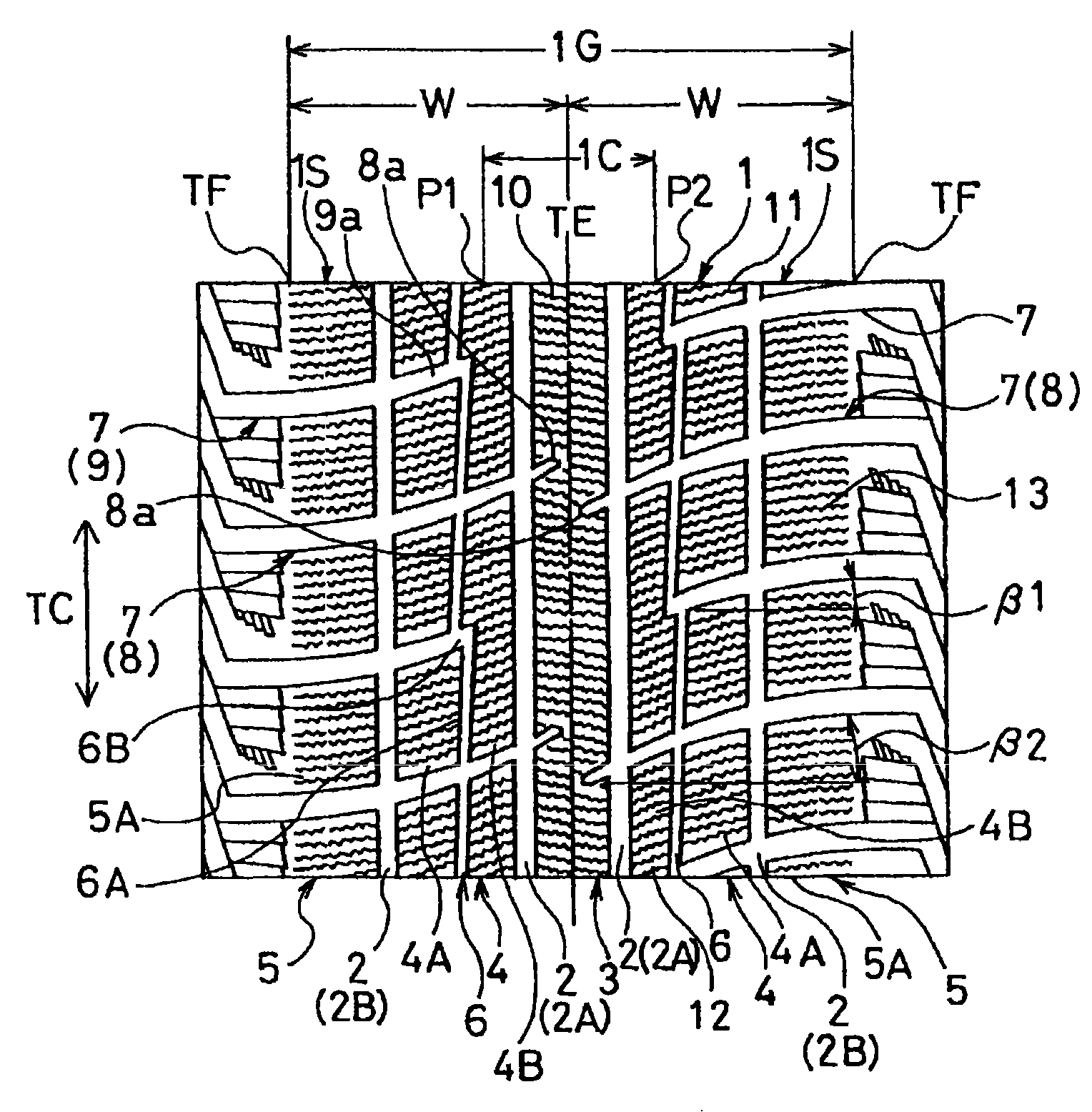

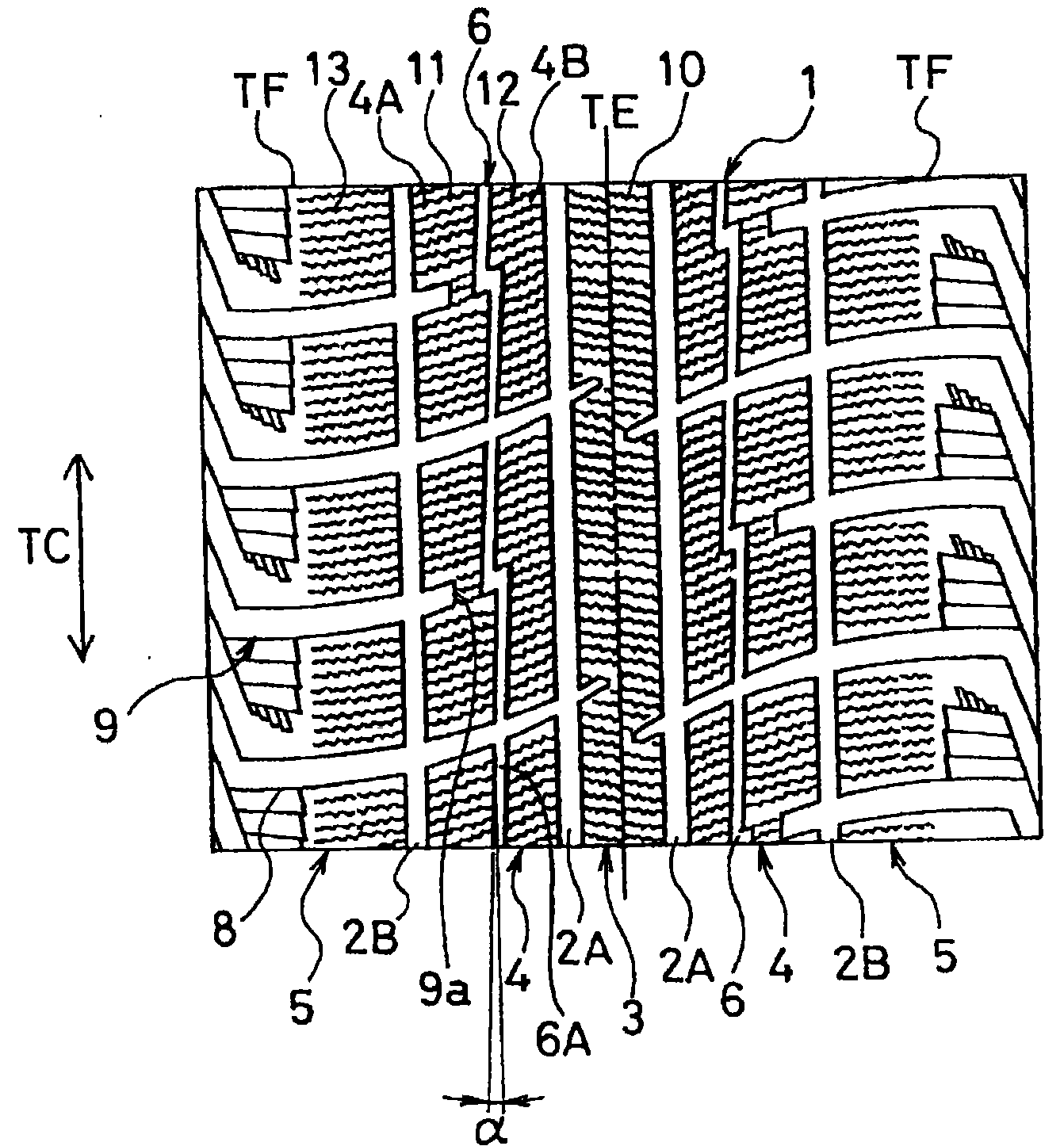

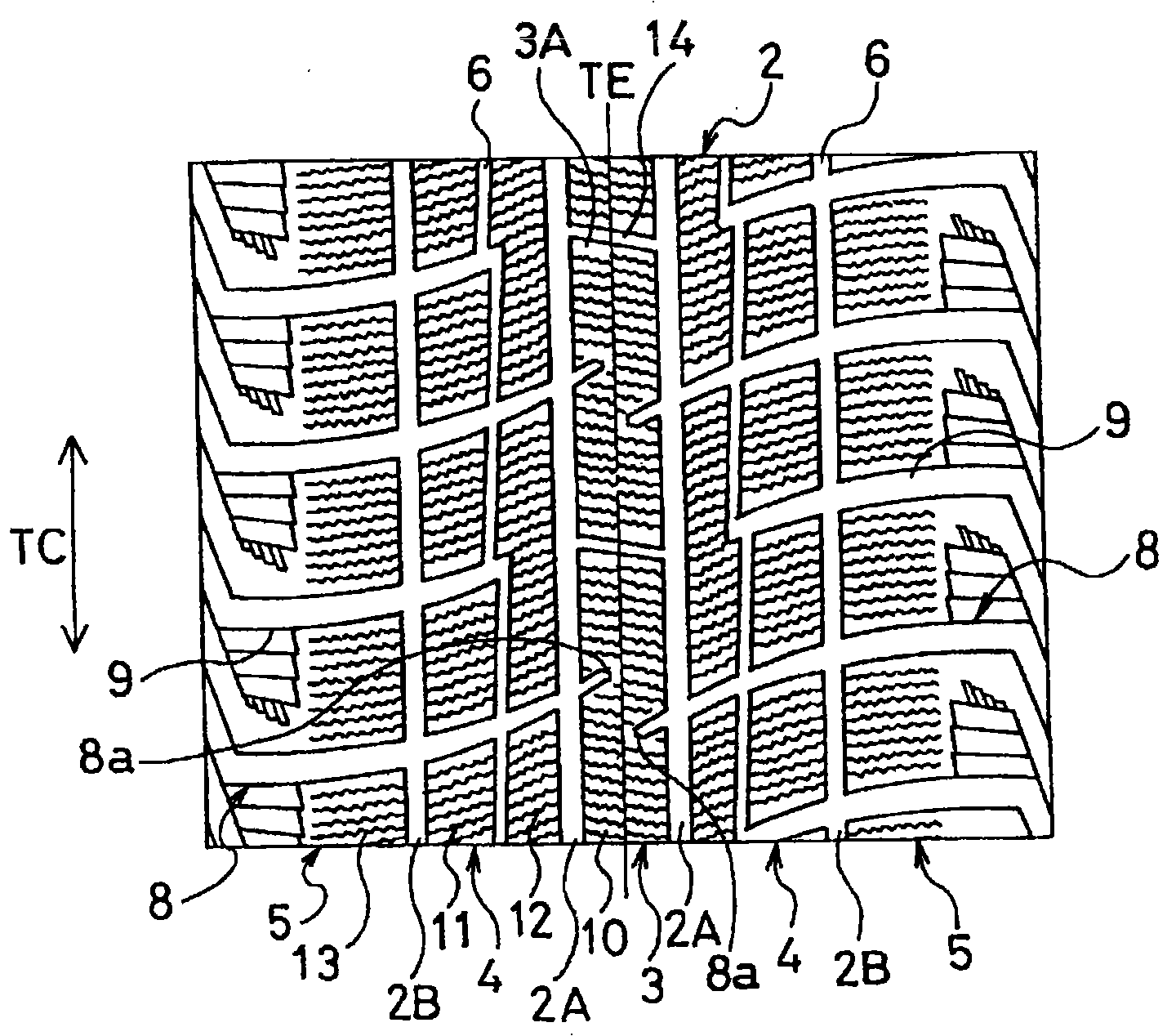

[0056] Tires 1 to 5 of the present invention (present Examples 1 to 5), comparative tires 1 to 4 (comparative examples 1 to 4), and conventional tires (conventional examples) were produced as test tires, respectively. The tire size of these tires is 215 / 60R16, and the tread pattern, the groove area ratio of the contact patch region, and the groove area ratio of the central region are shown in Table 1.

[0057] In the tires 1 to 5 of the present invention and the comparative tires 1 to 4, the angles β1 and β2 of the first lateral groove and the second lateral groove varied within the range of 0 to 37°, respectively. In addition, the inclination angles α of the first inclination portions of the sub grooves were each 5°.

[0058] These test tires were respectively assembled on rims with a rim size of 16×6.5J, and the air pressure was set to 230kPa, and mounted on front wheels with an ABS (anti-lock braking system, anti-lock braking system) displacement of 2500cc. On the driving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com