Floor processing system as well as rapid butt-joint method for floor treating device and charging stand

A processing device and processing system technology, which is applied in the installation of electrical equipment, two-dimensional position/channel control, machine components, etc., can solve problems such as increasing charging docking time, and achieve extended working time, improve processing efficiency, and accurately and efficiently. Quick docking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

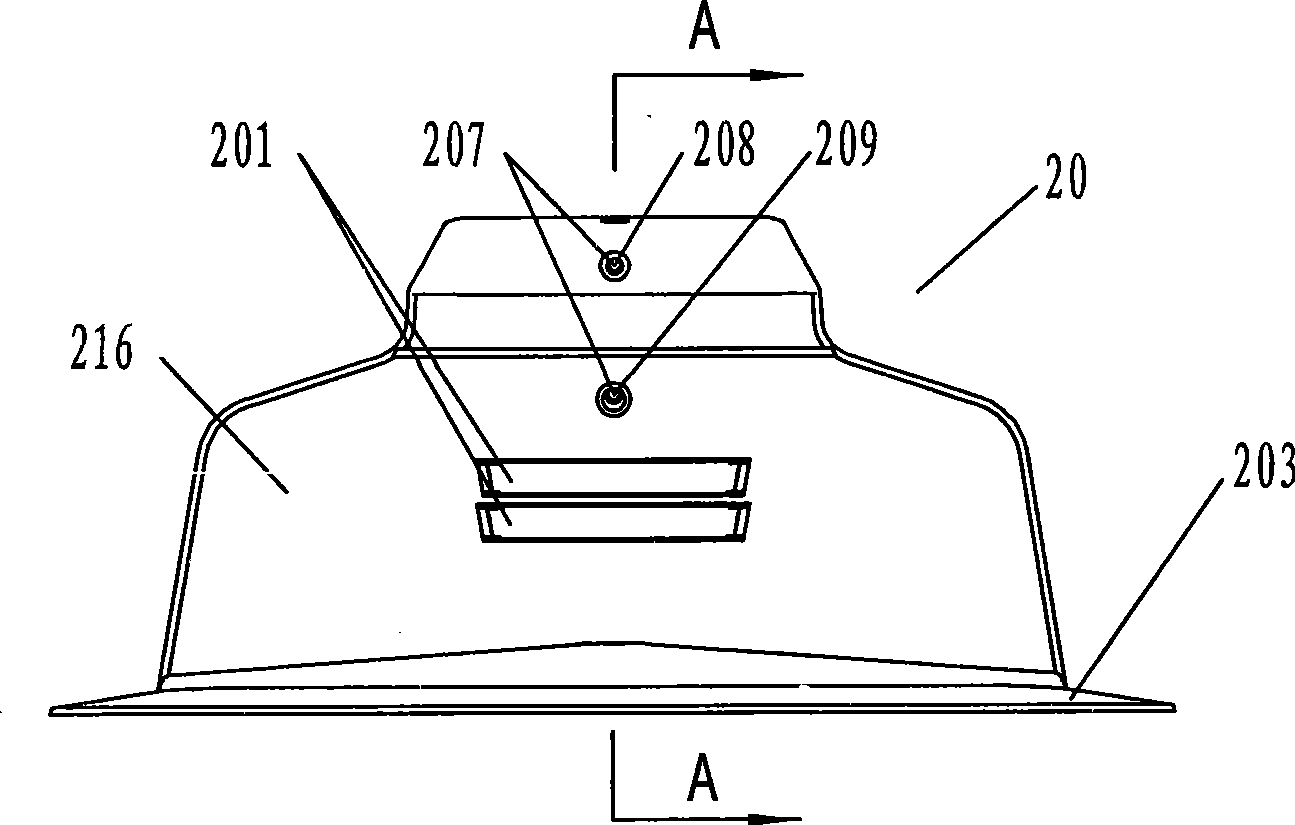

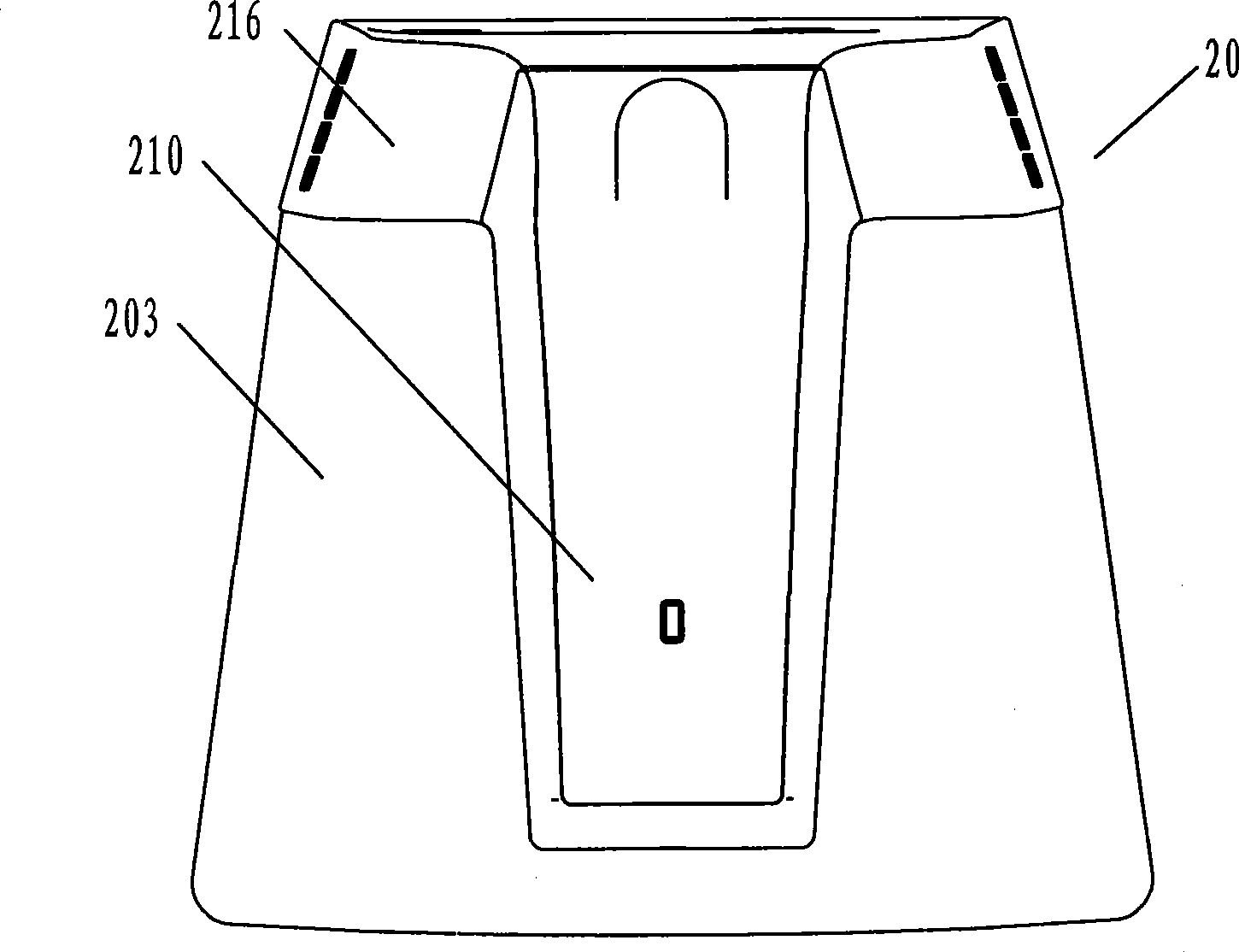

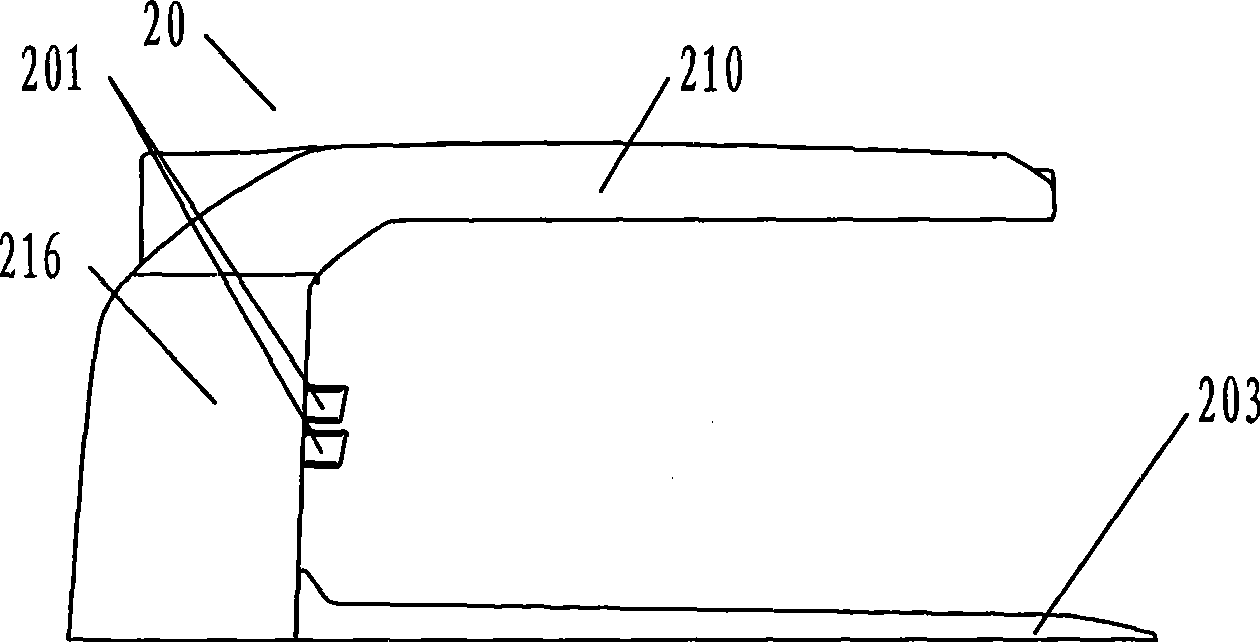

[0034] The invention discloses a ground treatment system, such as Figure 5As shown, a ground handling device 10 and a charging stand 20 are included. Same as the prior art, the ground treatment device 10 includes a casing 102, and a rechargeable energy supply unit (not shown in the figure) and a control unit (not shown in the figure) are arranged inside the casing 102 . The ground processing device 10 also includes a traveling mechanism, and two driving wheels 103 are respectively located on both sides of the ground processing device 10 and below the ground processing device 10, and each driving wheel 103 is respectively equipped with an electric motor (not shown) to drive . The electric motor is arranged inside the casing 102, and the energy is supplied by the energy supply unit, and the driving is controlled and driven by the control unit. The ground processing device 10 has a working mode and a charging mode. When the power of the energy supply unit is greater than or e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com