Rotor position estimation and correction method for permanent magnet synchronous generator

A generator rotor, permanent magnet synchronous technology, applied in the direction of controlling generators, electrical components, control systems, etc., can solve the problems affecting the reliability of the system, limiting the scope of use of the system, and the accuracy of the sensor is difficult to meet the requirements, and achieves good application prospects, Strong anti-interference ability, achieve simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below with reference to the accompanying drawings and examples. However, the invention is not limited to the examples given.

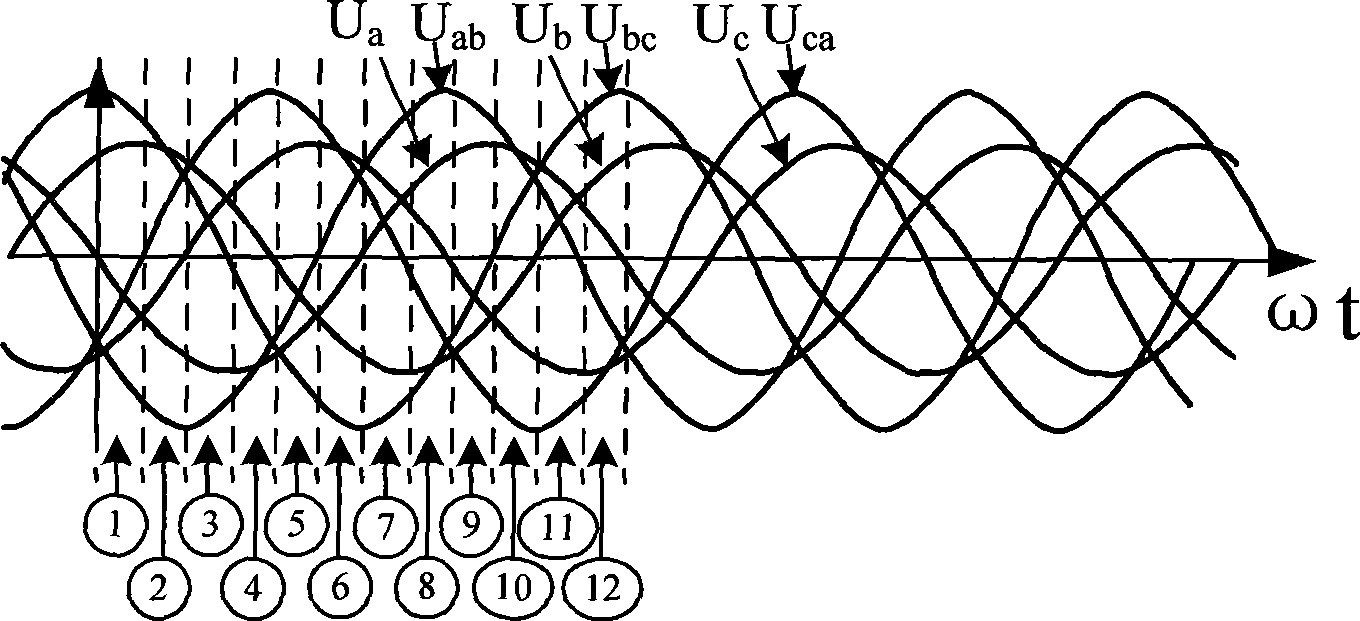

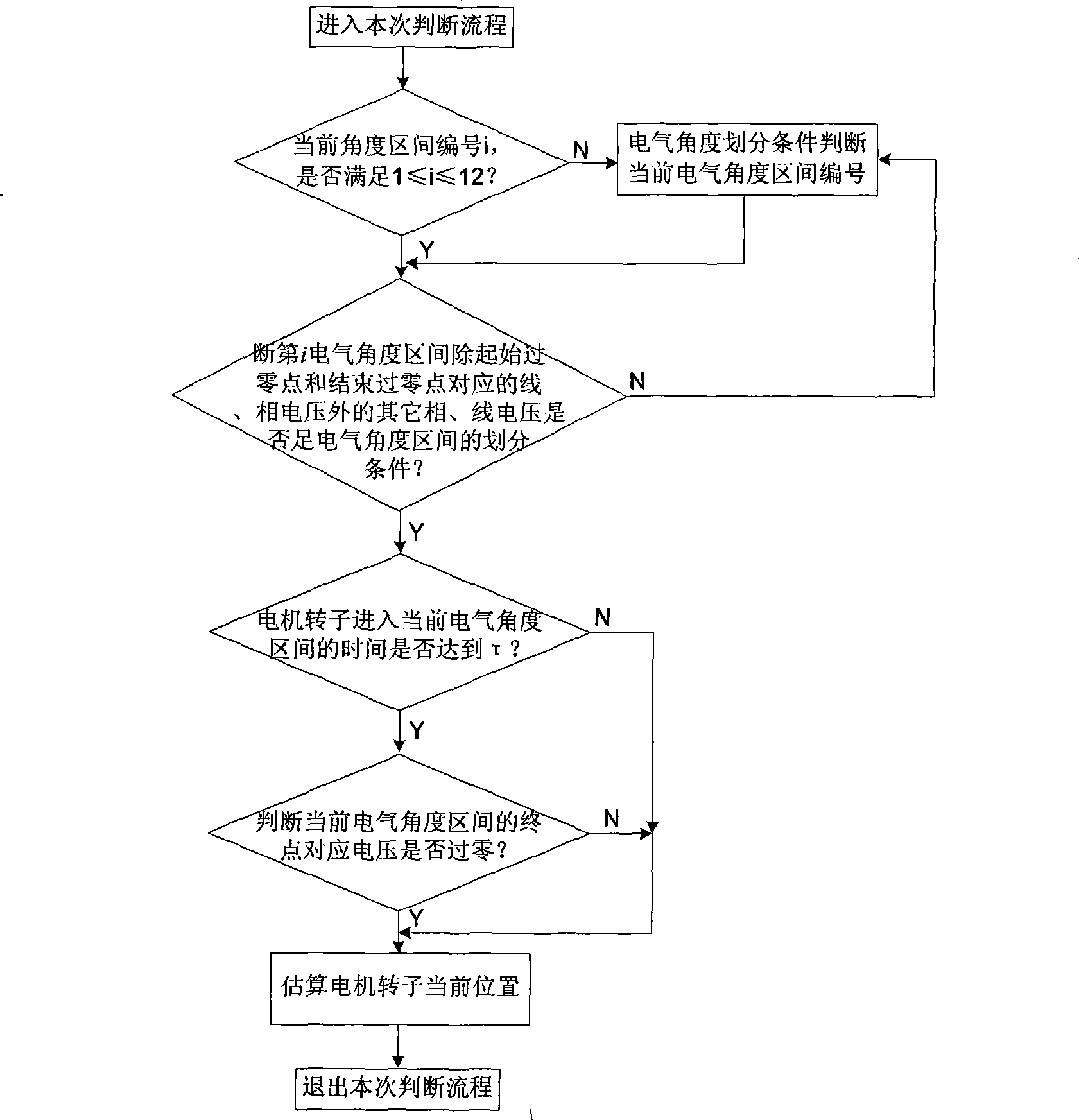

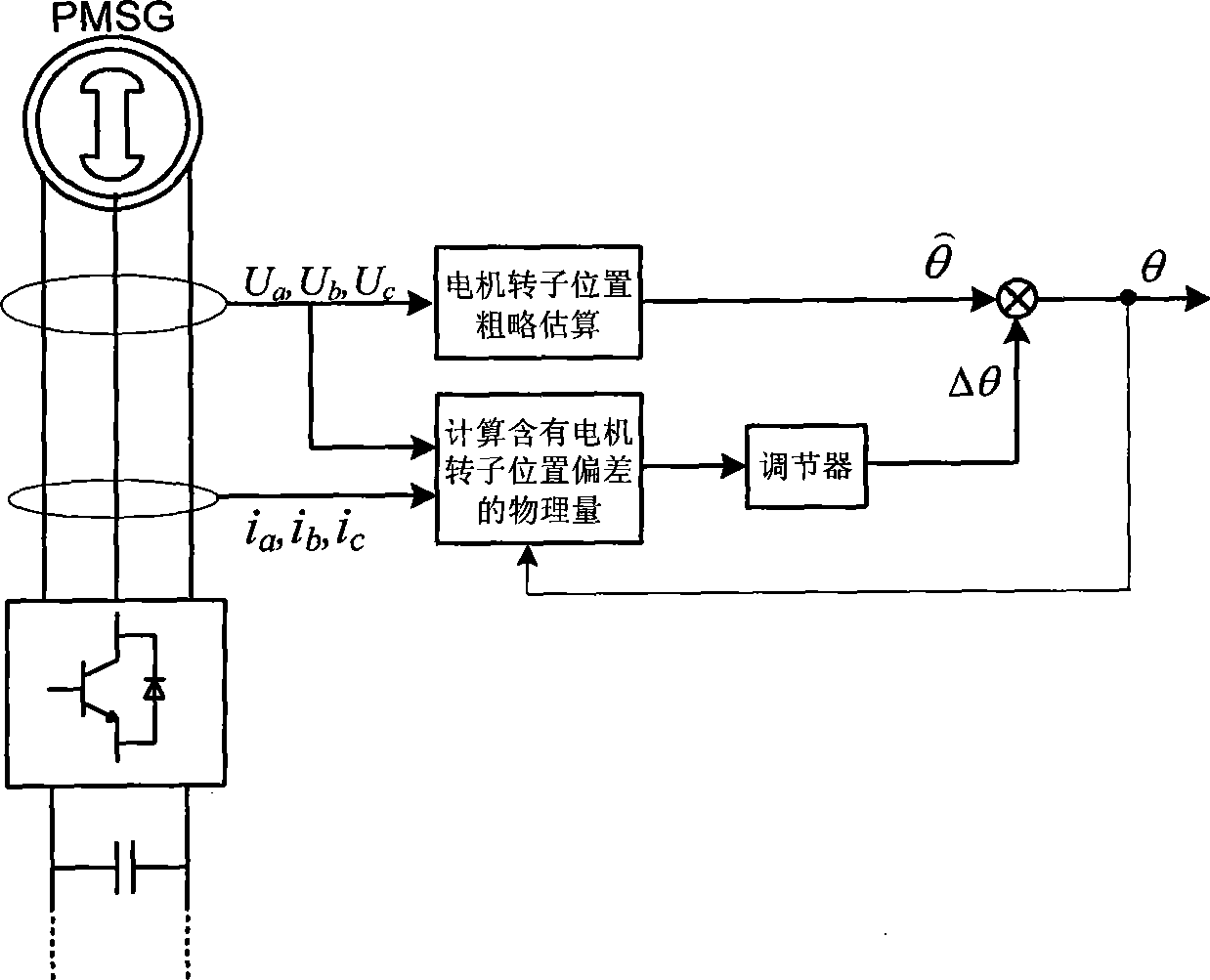

[0021] The invention is a method for estimating and correcting the rotor position of a permanent magnet synchronous generator. The method is to divide the 360° electrical angle of the motor rotor into 12 electrical angle intervals in sequence based on the zero-crossing points of the motor terminal phase voltage and the line voltage. (Such as figure 1 ), the 12 electrical angle intervals are sequentially recorded as the first to the twelfth electrical angle interval, and the starting point of the first electrical angle interval is 0° electrical angle of the motor, and each electrical angle The angle corresponding to the starting point of the angle interval is increased by 30° electrical angle in turn. The specific steps of this method are as follows, and the flow chart can be found in f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com