Device for separating liquids from gases

A gas and liquid technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of large installation space and increased complexity, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

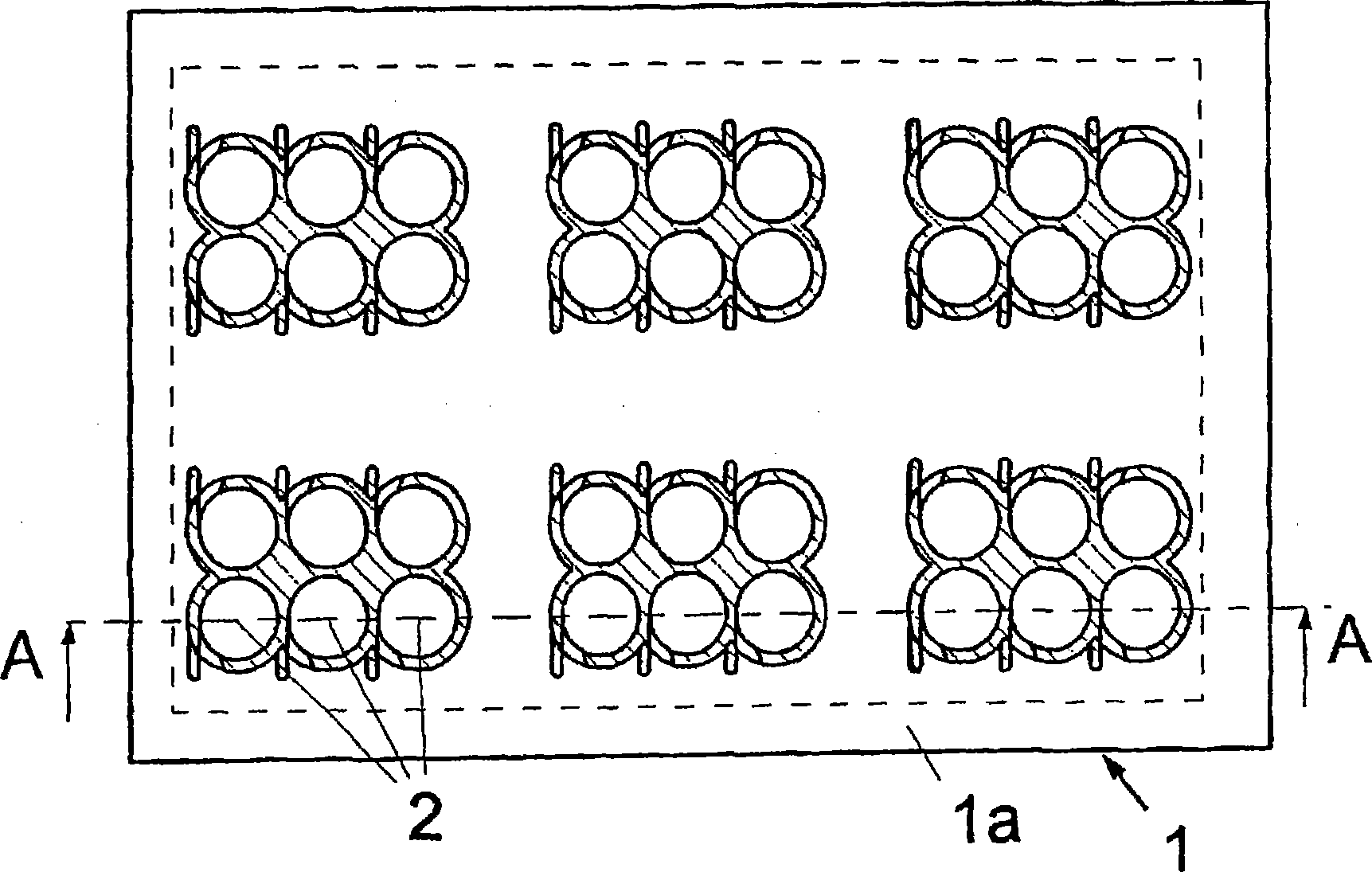

[0034] figure 1 The shown base 1 is designed as a plate-like plastic component with a large number of small integrally formed flow tubes 2 . The plate base 1 has a peripheral edge 1a. The base 1 has, for example, 30 to 40 flow tubes 2 arranged next to each other or in groups. The flow tube 2 has, for example, an inner diameter D of 5 mm and a length of 10 to 20 mm. exist figure 1 In the illustrated embodiment, six groups of six flow tubes 2 are provided.

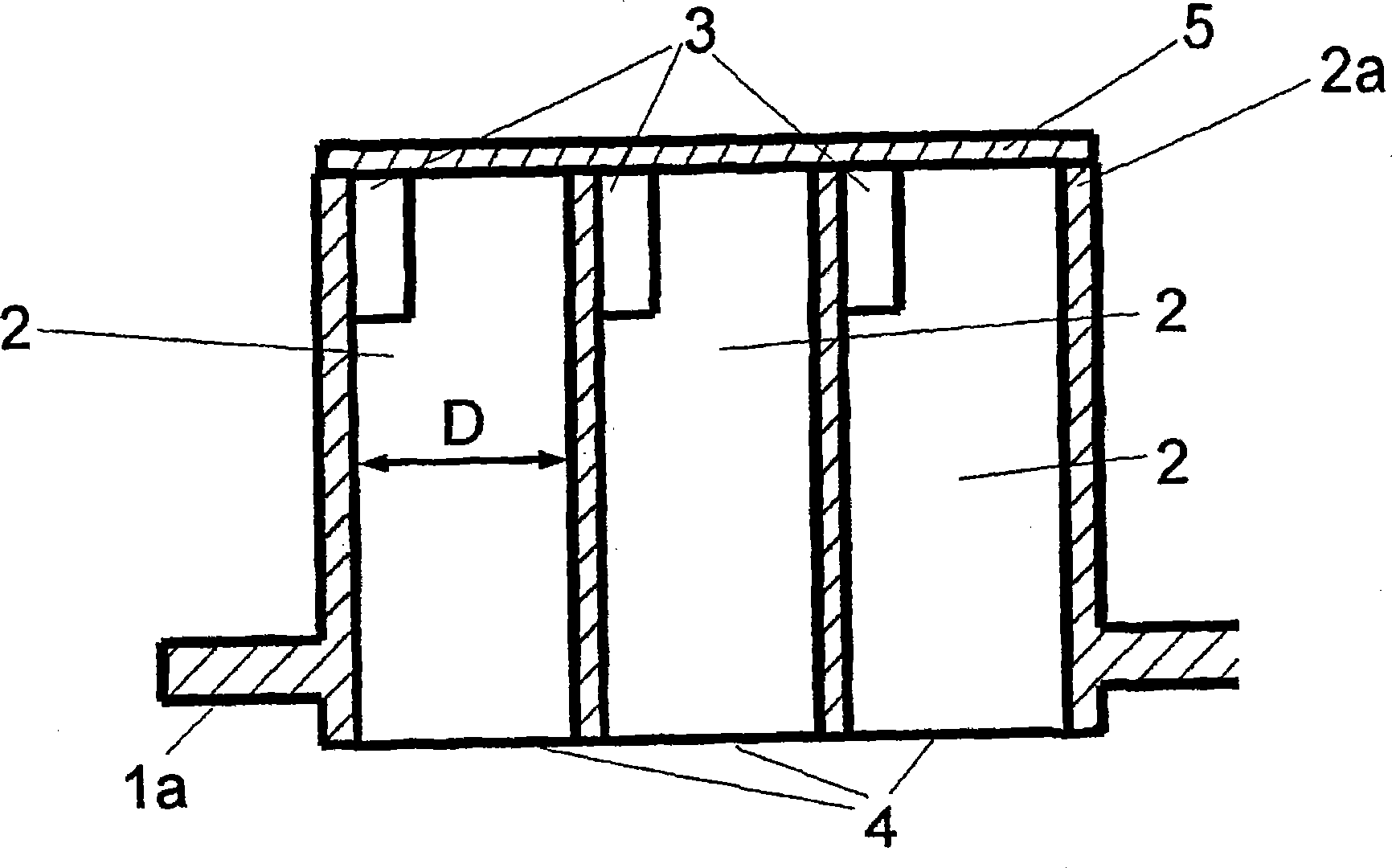

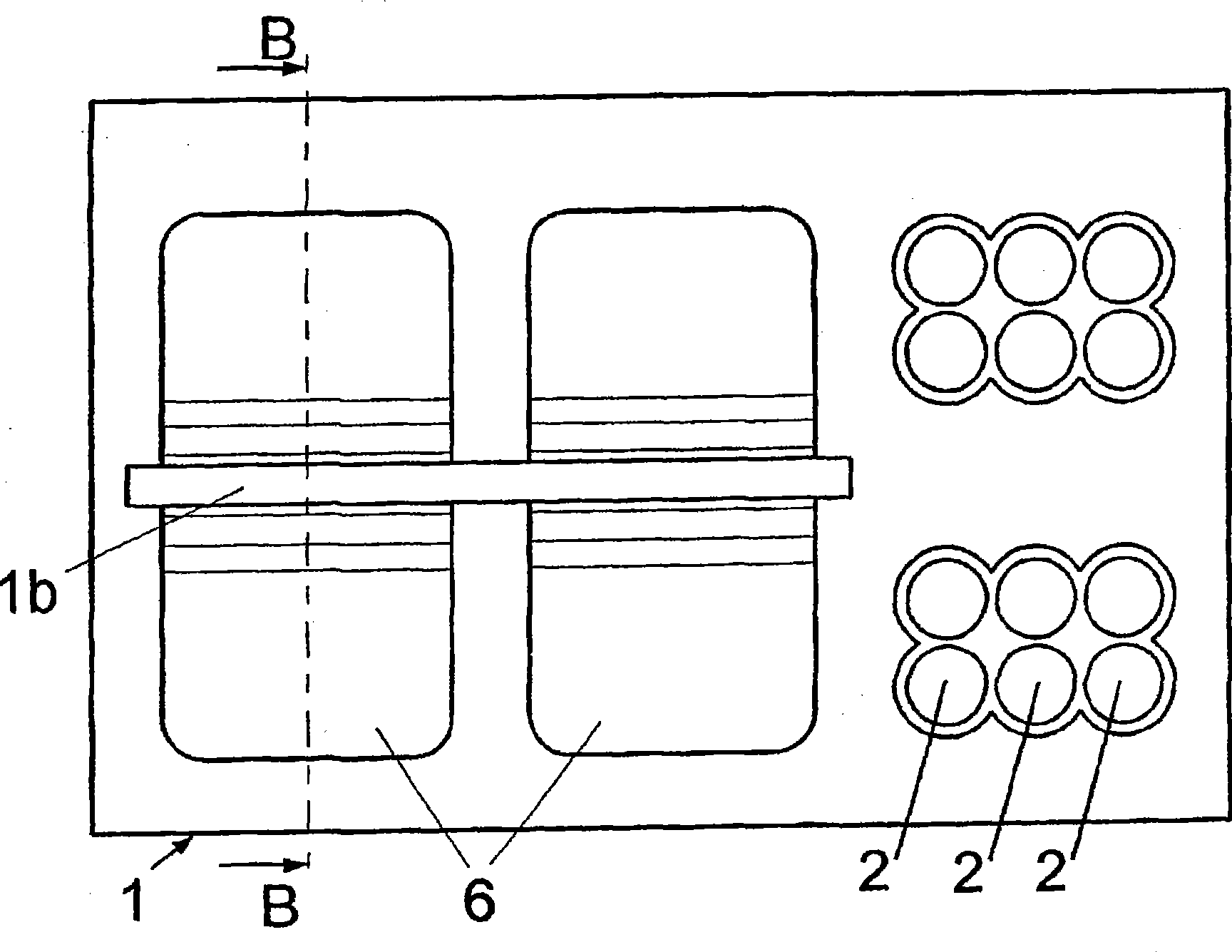

[0035] figure 2 A cross-section of a group with six flow tubes 2 is shown. Each flow tube 2 has a tangential feed gas inlet 3 and a gas outlet 4 through which clean gas and separated liquid flow out. The gas outlet 4 is almost on the same plane as the base 1 . Each flow tube 2 of equal length is closed at its end facing the gas inlet direction, at the front side 2a, by a cover plate 5 attached as shown in the exemplary embodiment. If the base 1 is made of plastic, the cover plate 5 can also be integrally molded to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com