Backlight suitable for display devices

A technology of display device and backlight source, applied in the field of backlight source, can solve problems such as light loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

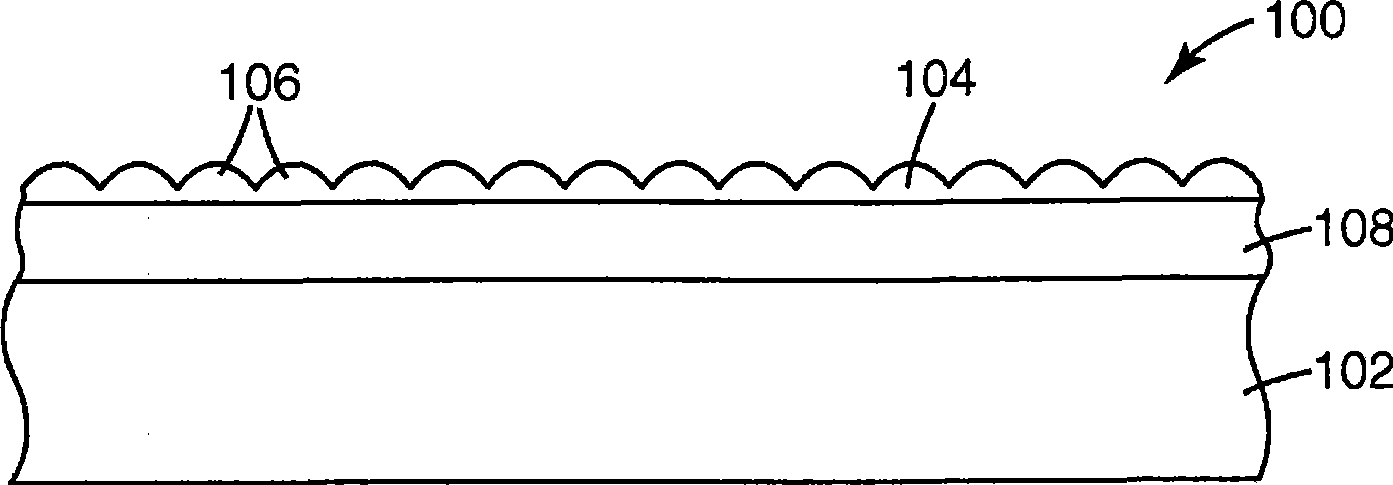

example 1

[0070] Image 6 and Figures 7A-7C It can be used to compare the bulbhiding capability of the new back reflector stack with the bulb hiding capability of available white diffusing back reflectors and available specular back reflectors. These figures were obtained using a Sharp 30" LCD TV, model No. LC-30HV4V with 10 bulbs. The original TV was equipped with 12 CCFL bulbs and a white back reflector. For the purposes of these examples, the back reflector device to modify. Image 6 Digital images were taken using a digital camera (Photometric Color CCD Light Measurement System from Radiant Imaging Co, (Duvall, Washington, USA)). The vertical lines show where the luminance distribution was obtained for three different back reflector regions, resulting in Figures 7A-7C .

[0071] With the original TV, the image of the CCFL bulb can be seen on the screen, which means that the brightness uniformity is poor, which is the case in Image 6 the leftmost part of and Figure 7A shown...

example 2

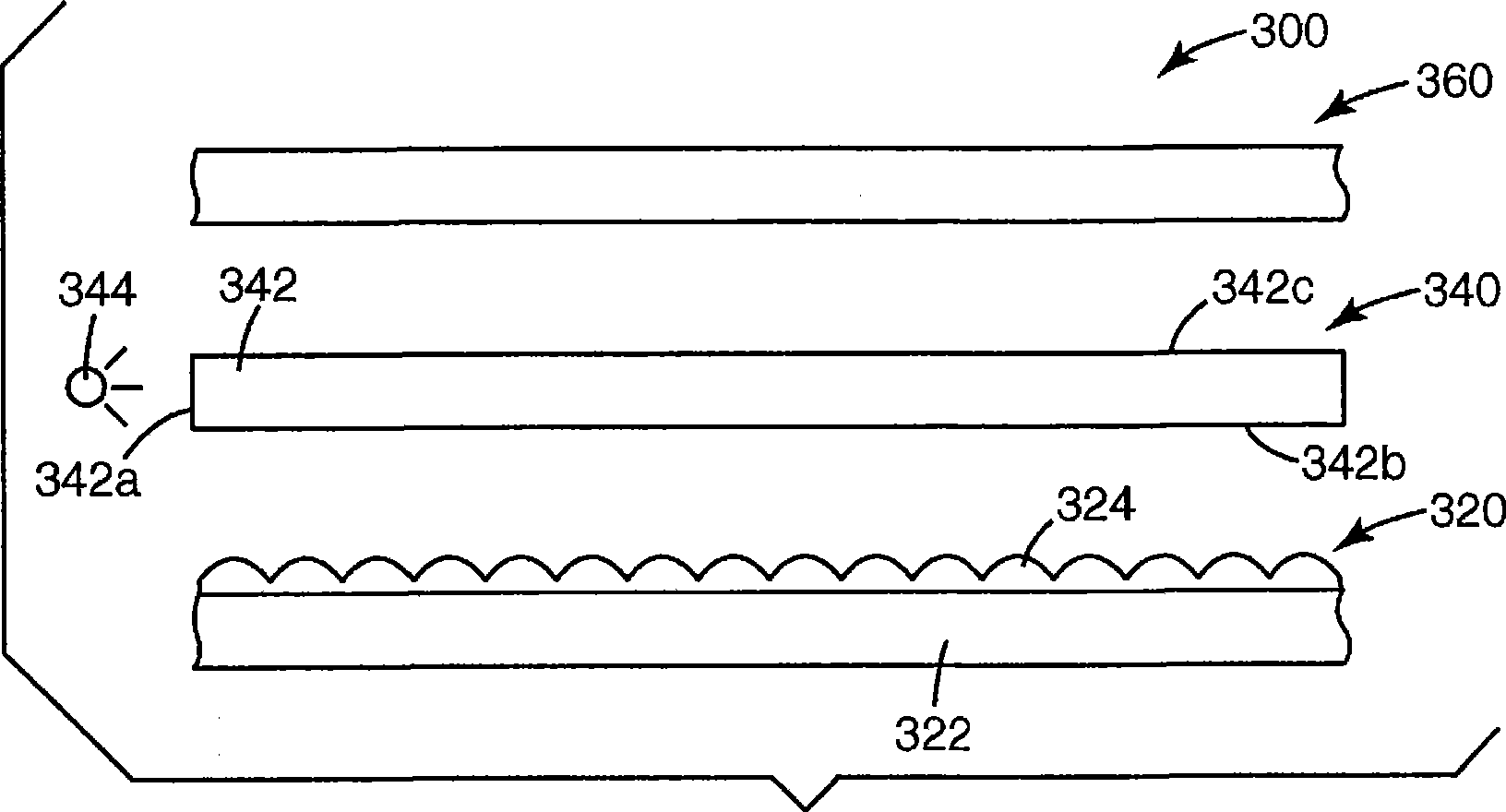

[0075] This example shows that exemplary reflector stacks in accordance with the present invention can improve brightness uniformity more effectively than conventional diffuse reflectors. The backlight in this example is a test bench with 35mm bulb pitch and 17mm cavity depth, which is close to a conventional 32" liquid crystal digital television (LCDTV) based on 12 bulbs. The top film includes a 2mm diffuser plate and is coated on DBEF with BEF prism on it (DTV).

[0076] With the exception of the exemplary reflector stack according to the present invention, which is the same as the reflector stack in Example 1, the output luminance uniformity of the diffusely reflective films including common diffuser films with different haze levels was tested in a test bench degree of improvement. Diffusion films with haze levels of 35%, 45% and 60% (measured by a Haze-gard Plus haze meter manufactured by BYK Gardner (Silver Spring, Maryland, USA)) were laminated to the ESR and tested in ...

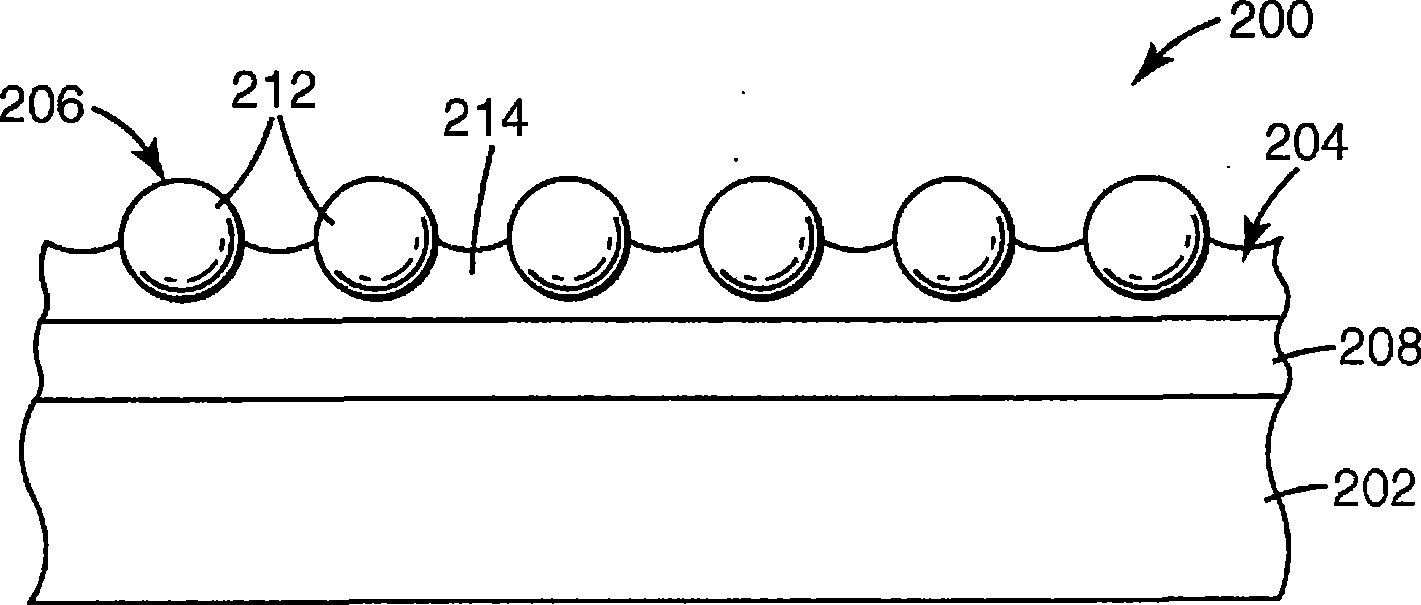

example 3

[0078] For this example, the clear layer was the same beaded diffuser used in Example 1 - a beaded diffuser "OPALUS BS-04" from Keiwa with a thickness of 140 μm on a 100 μm polyethylene terephthalate substrate, which The haze was measured to be 89.5% with a Haze-gard Plus haze meter from BYK Gardner (Silver Spring, Maryland, USA). The clear layer was laminated to the ESR film by using an Opt1 pressure sensitive adhesive (PSA).

[0079] Three test rigs with bulb pitches of 25mm, 30mm and 35mm were used. Different combinations of front films were used, including commercially available beaded diffusers (GD) suitable for LCD TVs, DBEF (D400), BEF, and DBEF with BEF. A standard white reflector and a back reflector stack according to the invention were used as back reflectors. Figure 9 and Figure 10 Test results are shown comparing the performance of a back reflector stack according to the present invention ("modified ESR") to that of a conventional white diffuse back reflector...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com