Anti-peeping brightening film and preparation method thereof

A technology of brightness enhancement film and privacy protection film, applied in the field of privacy protection brightness enhancement film and its preparation, can solve the problems of reducing the brightness of a liquid crystal display screen, reducing the light transmittance of the privacy protection film, unfavorable user observation, etc. Peep effect, shorten vulcanization time, avoid scratch effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

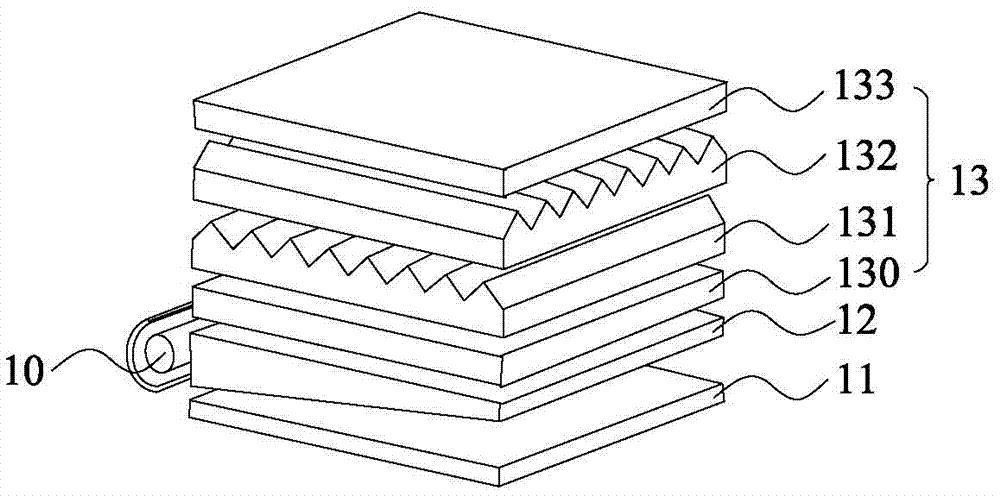

[0070] Such as figure 1 As shown, the backlight module of the prior art includes a backlight 10, a reflective film 11, a light guide plate 12 and an optical film group 13, wherein the optical film group 13 includes a lower diffusion film 130, a lower brightness enhancement film 131 , upper brightness enhancement film 132 , and upper diffusion film 133 .

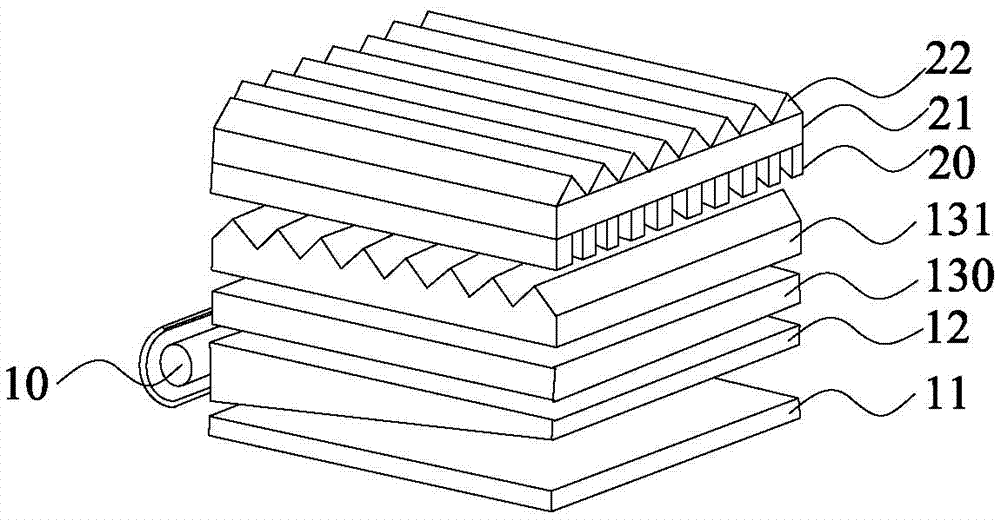

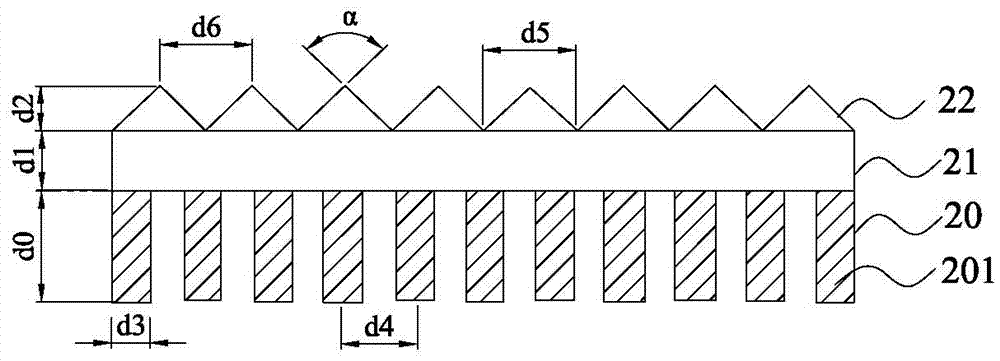

[0071] Such as Figure 2-3 As shown, the anti-peeping brightness enhancement film provided by the present invention can replace the upper brightness enhancement film 132 and the upper diffusion film 133 of the traditional backlight module. An anti-peeping brightness enhancement film of the present invention comprises a base material layer 21, a prism structure layer 22 and an anti-peeping film layer 20, the base material layer 21 comprises a first optical surface and a second optical surface, and the prism structure layer 22 is coated on the first optical surface, and the anti-peeping film layer 20 is coated on the second o...

Embodiment 2

[0100] Such as Figure 4-6 Shown, the difference between this embodiment and embodiment 1 is:

[0101] The raw material composition and parts by weight of the rib structure unit 201 are:

[0102] Acrylic resin 100 parts

[0103] Reflective material 5 parts

[0104] Described acrylic resin is polyester acrylic resin;

[0105] The reflective material is titanium dioxide, and the particle diameter of the titanium dioxide is 10 μm.

[0106] Further, the raw material composition and parts by weight of the prism structure layer 22 are:

[0107] Acrylic monomer 80 parts

[0108] Cross-linking agent 10 parts

[0109] Photoinitiator 10 parts

[0110] The acrylic acid monomer is 2-dioxyacrylate.

[0111] The crosslinking agent is trimethylolpropane triacrylate.

[0112] The photoinitiator is 2,4,6-trimethylbenzoyl diphenyl phosphorescence initiator.

[0113] Further, the height d0 of the rib-shaped structural units 201 is 50 μm, the width d3 is 125 μm, and the distance d4 betw...

Embodiment 3

[0120] Such as Figure 2-6 Shown, the difference between this embodiment and embodiment 1 is:

[0121] The raw material composition and parts by weight of the rib structure unit 201 are:

[0122] Acrylic resin 95 parts

[0123] Reflective material 10 parts

[0124] Described acrylic resin is epoxy acrylic resin;

[0125] The reflective material is silicon dioxide, and the diameter of the silicon dioxide particles is 2 μm.

[0126] Further, the composition and parts by weight of the prism structure layer 22 are:

[0127] Acrylic monomer 80 parts

[0128] Cross-linking agent 5 parts

[0129] Photoinitiator 17 parts

[0130] The acrylic acid monomer is 2,4,6-tribromophenoxyethyl acrylate.

[0131] The crosslinking agent is pentaerythritol triacrylate and trimethylolpropane triacrylate, and the mass ratio of the two is 1:1.

[0132] The photoinitiator is a double titanocene photoinitiator.

[0133] Further, the height d0 of the rib-shaped structural units 201 is 25 μm, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com