Interactive treating process for advance treatment and recycle of waster water from oil production

A technology for advanced treatment of oil production wastewater, applied in biological water/sewage treatment, flotation water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of low quality chemicals, long process, large floor area, etc. Achieve the effect of controlling water treatment cost, efficient treatment and improving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

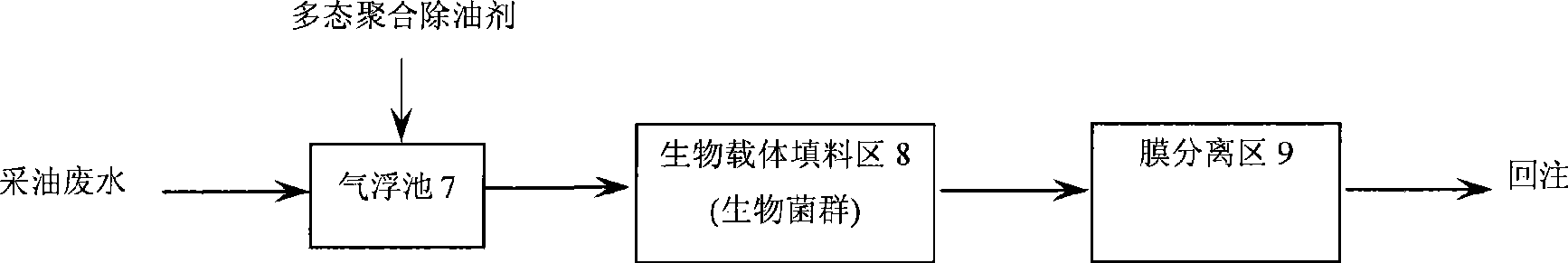

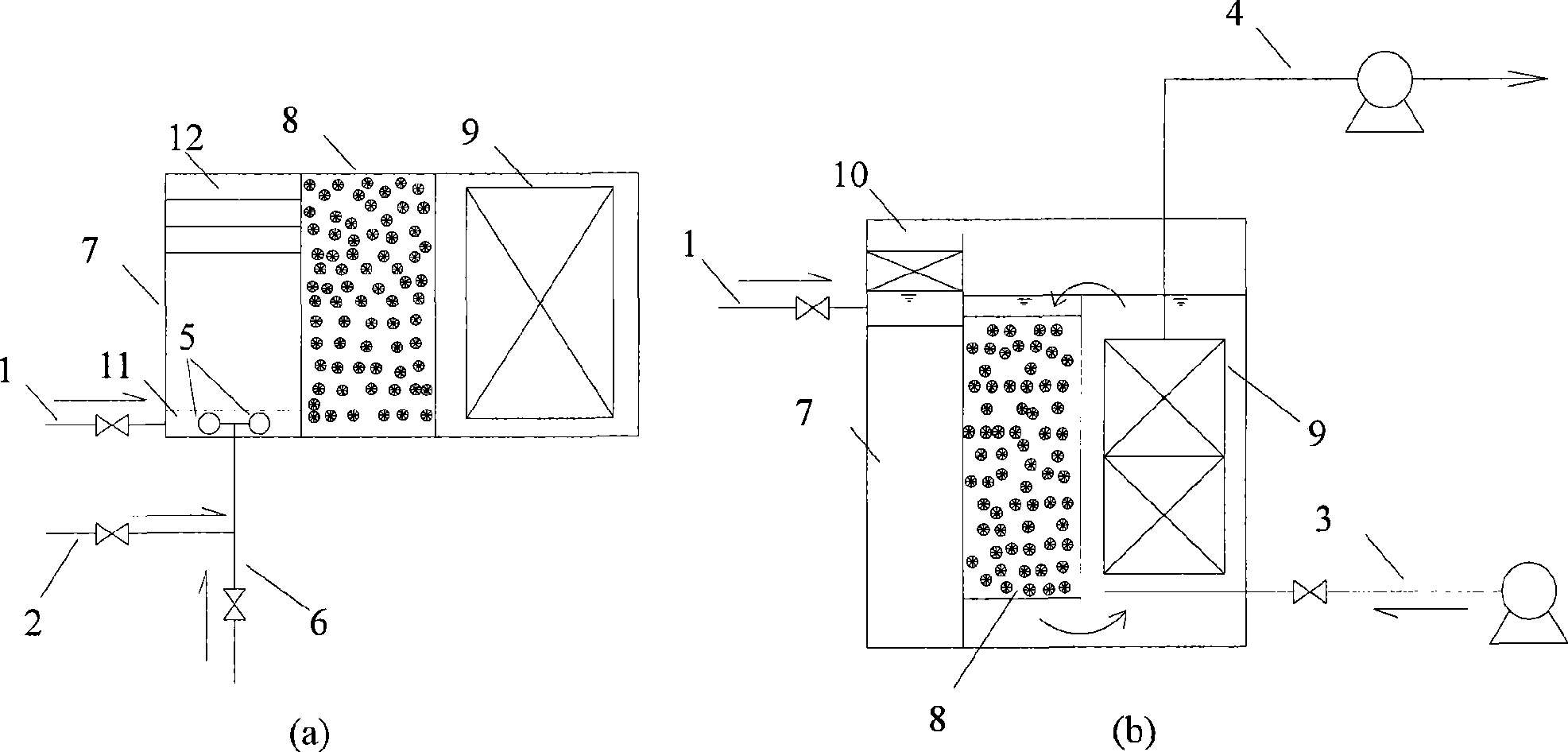

[0019] Example 1: The process of the present invention mainly consists of air flotation tank 7, biological carrier packing area 8, and membrane separation area 9 (which can be combined to form an integrated degradation and separation reactor) and other main processes, including water inlet pipe 1, degreasing agent injection The inlet 2, the air supply system 3, and the water outlet pipe 4, etc. The oil production wastewater enters the water distribution area 11 of the air flotation tank 7, and a dissolved air release device 5 is provided in the water distribution area 11 to release microbubbles under high pressure conditions. After the microbubbles adhere to the oily substances, they rise to the surface of the air floatation tank 7, and pass The oil scraper 10 removes the oil residue. The high-pressure dissolved gas pipeline 6 is provided with a degreaser injection port 2 at the same time, which is released by the dissolved gas release device 5 to the water distribution area 11 to...

Example Embodiment

[0021] Example 2

[0022] The process described in Example 1 is used to treat oil production wastewater. The daily output of oil production wastewater in an oil field is 1000 tons, and the wastewater quality is: petroleum 150-220mg / L; COD 800-1400mg / L; BOD 80-140mg / L; sulfide Substance 120-400mg / L; Volatile phenol 2-9.0mg / L. Waste water is treated by this treatment process (e.g. figure 1 Shown), under the condition that the overall hydraulic retention time of the equipment is 3.5h, and the dosage of polymorphic polymer degreasing agent is 20mg / L-inlet water, use figure 2 In the case of the structural arrangement shown, the total floor area of the water treatment structure is 48.6m 2 . The oil production wastewater of this oilfield is treated by this treatment process, and the treated water quality has reached the A1 standard (average air permeability of the injection layer) in the "Recommended Indexes and Analysis Methods for Water Injection Quality of Clastic Rock Reservoirs (...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap