Axial force self-balancing multiple stage centrifugal pump

A self-balancing, axial force technology, applied in radial flow pumps, pumps, pump devices, etc., can solve problems such as the inability to completely eliminate the balancing force, wear of the pump balancing mechanism, affecting the service life of the pump, etc., and prolong trouble-free operation. Time, avoid mechanical friction, reduce the effect of equipment maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

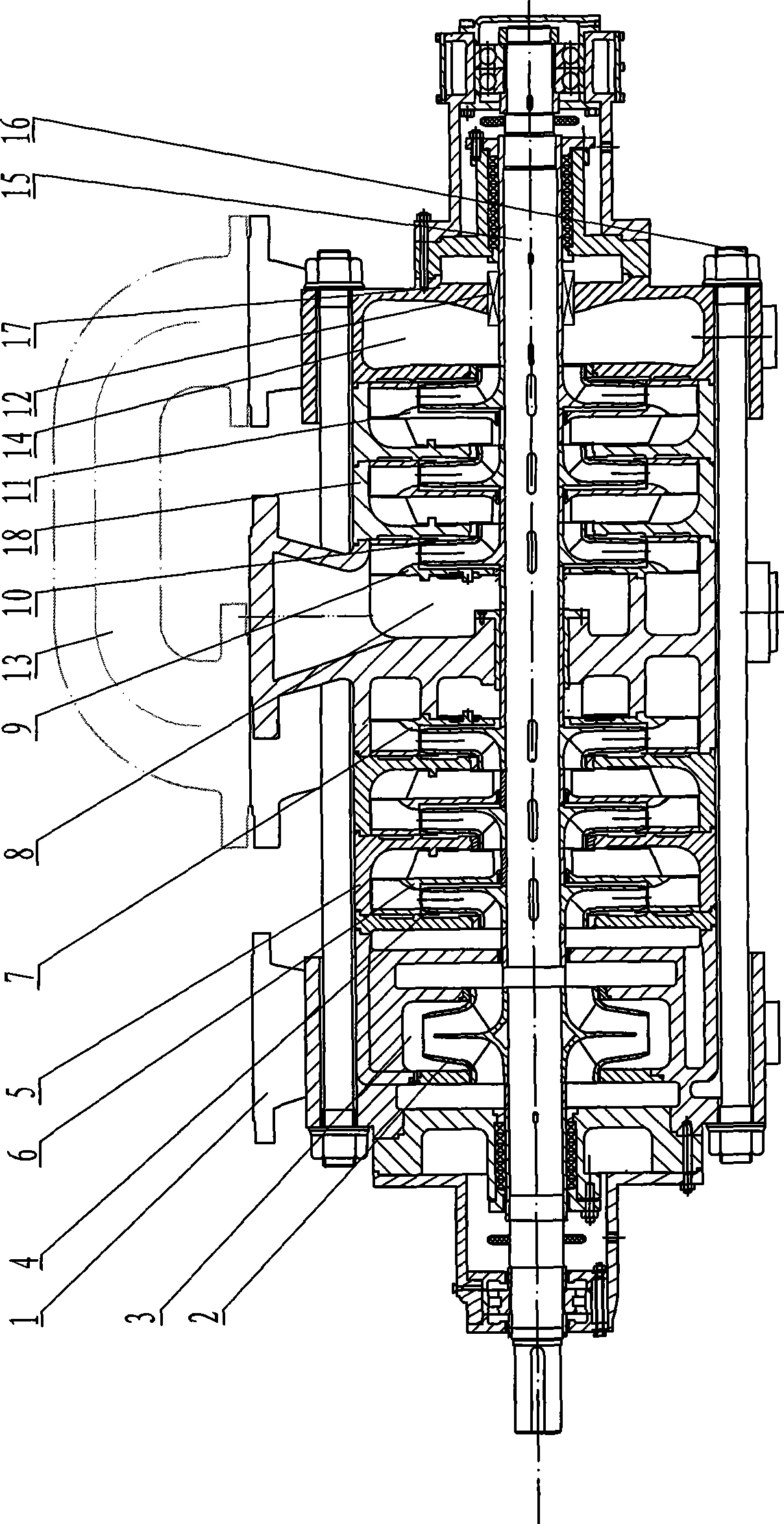

[0012] like figure 1 Among them, an axial force self-balancing multistage centrifugal pump includes a pump body 17 and tension bolts 16, the first-stage impeller 2 is installed in the front section 3 of the pump body 17 through a shaft 15, a plurality of left impellers 4 and a plurality of right The impellers 10 are symmetrically installed on the shaft 15, a plurality of left impellers 4 are installed in the front pump chamber 5, a plurality of right impellers 10 are installed in the rear pump chamber 18, the front section 3 communicates with the front pump chamber 5, and the front pump chamber 5 is replaced by The flow passage 13 communicates with the rear section 14 , the rear section 14 communicates with the rear pump chamber 18 , and the rear pump chamber 18 communicates with the discharge section 8 .

[0013] When the total number of impellers in the front pump chamber 5 and the rear pump chamber 18 was an odd number, the many first-stage impellers were the left impeller ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com