Method for filling sandwich layer thermal insulating material for deep cooling container and special filling apparatus

A technology of thermal insulation material and filling method, which is used in pressure vessels, fixed-capacity gas storage tanks, mechanical equipment, etc., to ensure the filling speed and uniformity, the retention time, and the ease of equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1, a method for filling the interlayer insulation material of a cryogenic container: mainly includes the following steps:

[0019] a. Fill the sealed filling material storage tank with nitrogen to discharge the air in it. For the humid environment, the tank should be heated to 140°C to ensure that the filling is dry.

[0020] b. Vacuumize the interlayer of the cryogenic container to 30-50pa.

[0021] c. In the state of continuous vacuuming, slowly open the valve on the pipeline connecting the filling material storage tank and the interlayer of the cryogenic container, keep the nitrogen pressure at 0.2Mpa, and the filling material fills the interlayer of the cryogenic container under the pressure of nitrogen.

[0022] d. When filling to 80% of the design density, close the connecting valve and increase the pressure of the filling material tank to 0.6MPa. At the same time, the interlayer of the cryogenic container is vacuumed to 5-15Pa. Quickly open the Unico...

Embodiment 2

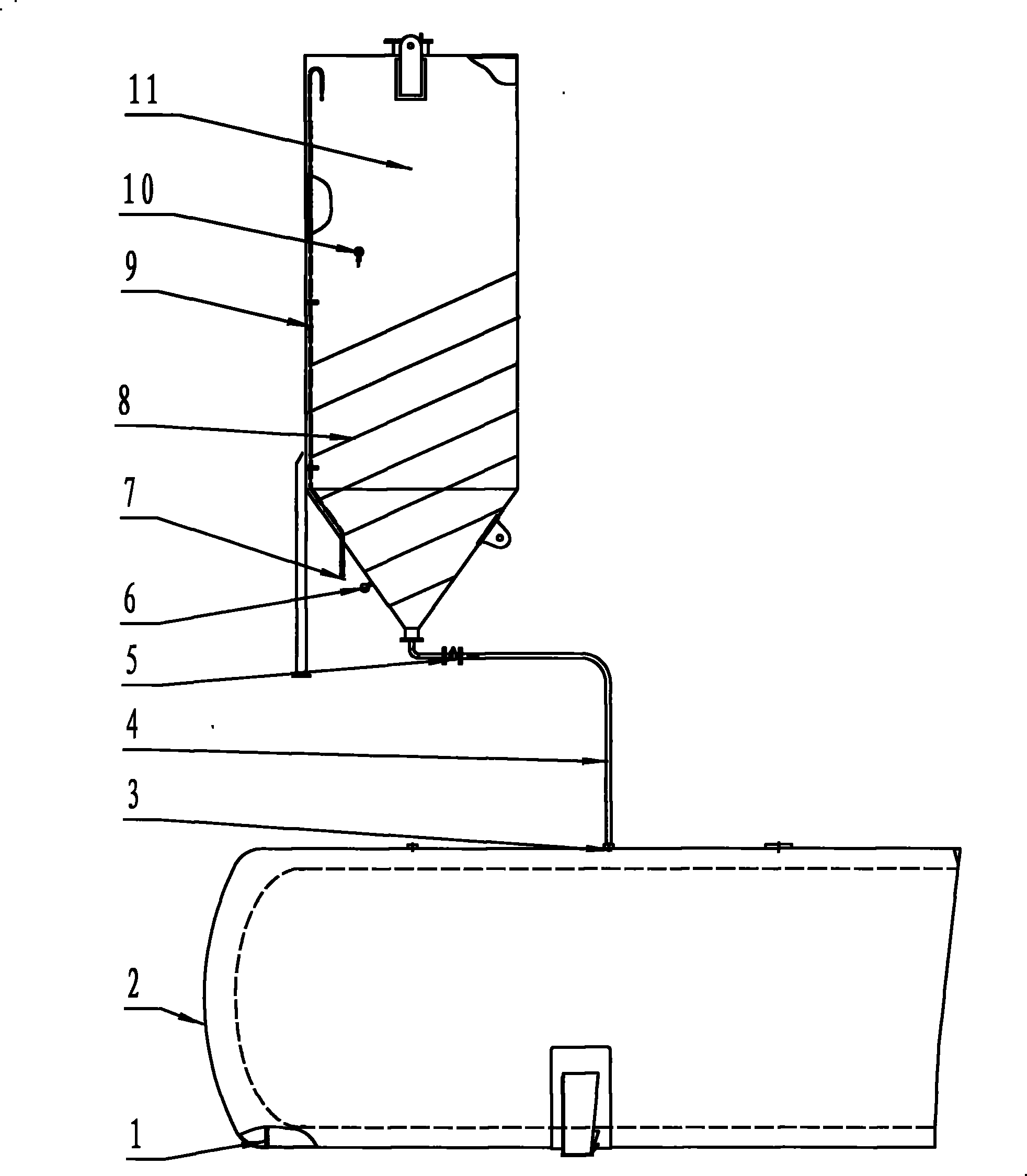

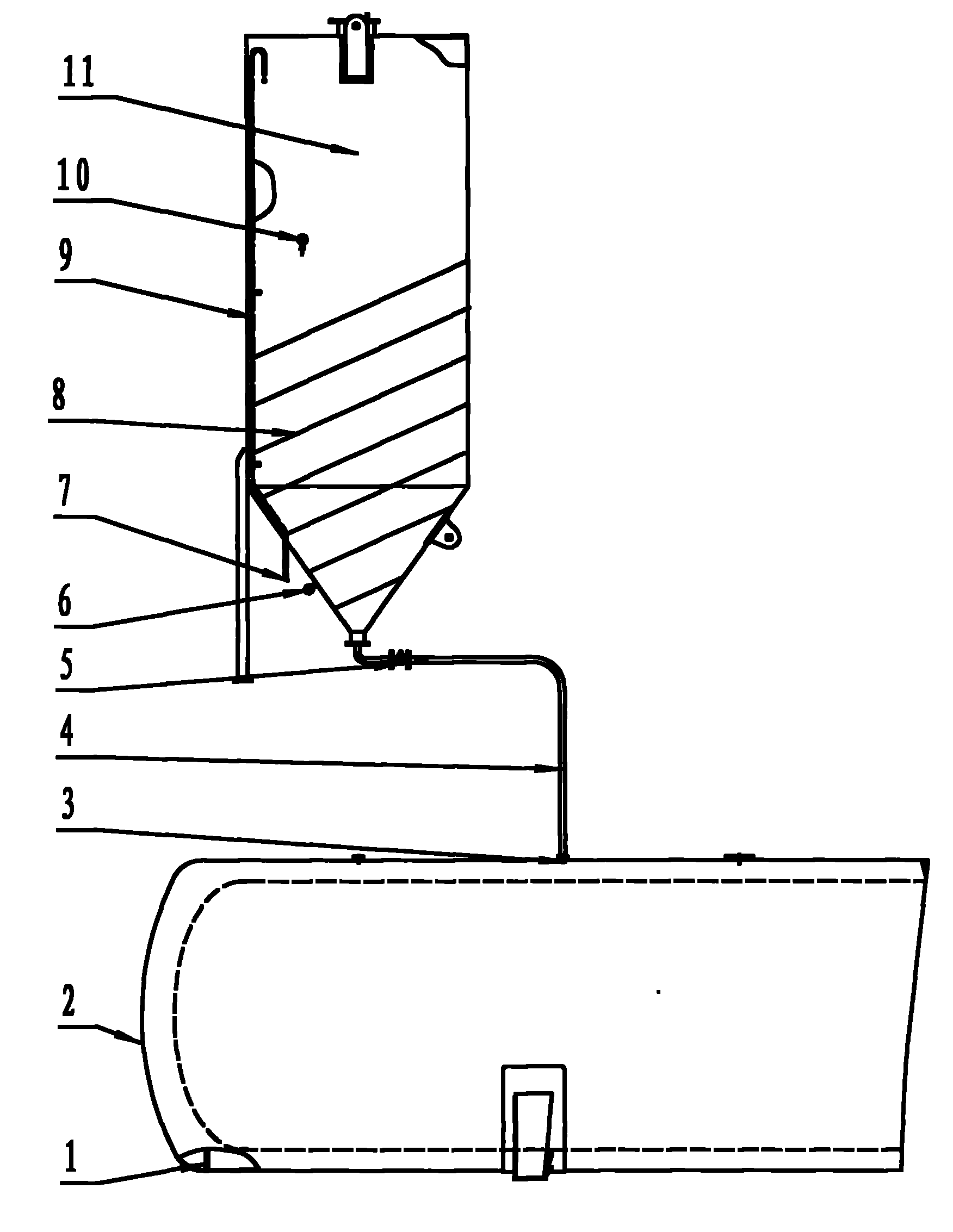

[0025] Embodiment 2, the special device used in the filling method of the interlayer insulation material of the cryogenic container, its structure is: a vertically installed filling material storage tank 11, the lower part is conical, and a pressure gauge 6 and a nitrogen inlet 7 are installed on the conical surface. The conveying pipe 9 goes upward along the tank body, and its outlet is on the top of the storage tank. The conical bottom end of the tank body is equipped with a filling material conveying pipe 4 connected to the filling material filling hole 3 of the cryogenic container 2. The conveying pipe is equipped with a quick-opening valve 5. The cryogenic container is provided with air extraction holes. When the environment is moderately large, first open the heating coil device 8, and then carry out the above filling work after the thermometer 10 shows that it rises to 140°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com